Preparation method of monodisperse hollow mesoporous silica nanoparticle

A technology of mesoporous silica and nano-microspheres, applied in the direction of silica, silicon oxide, chemical instruments and methods, etc., can solve the problems of hollow mesoporous silica with rough surface, poor sphericity, and uneven scale , to achieve the effect of high sphericity, uniform scale and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

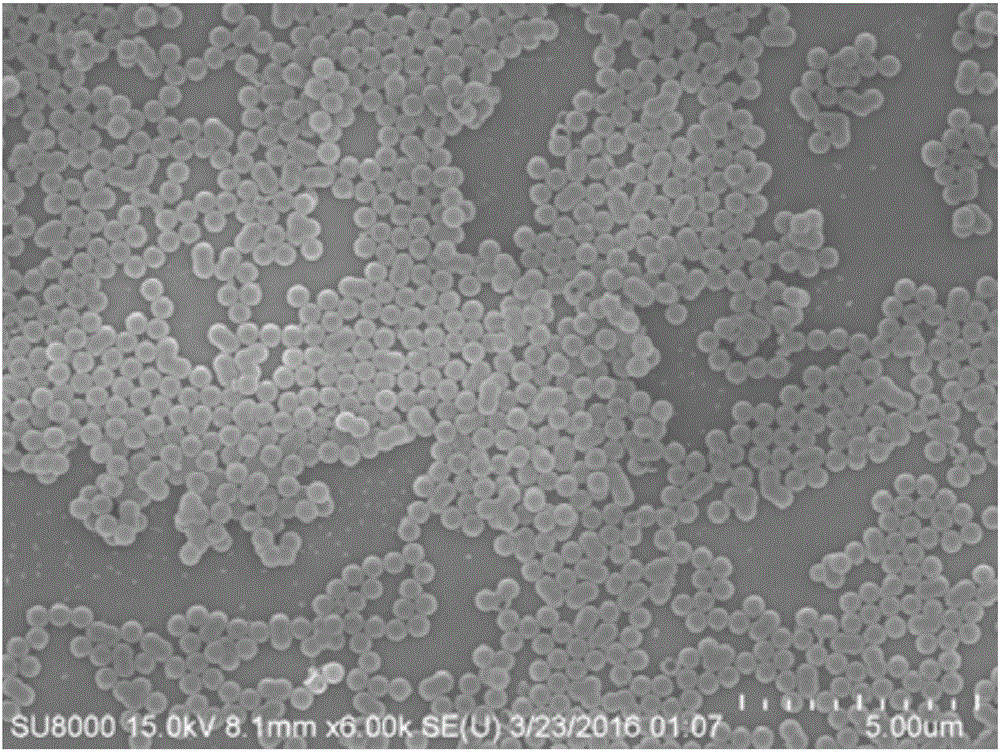

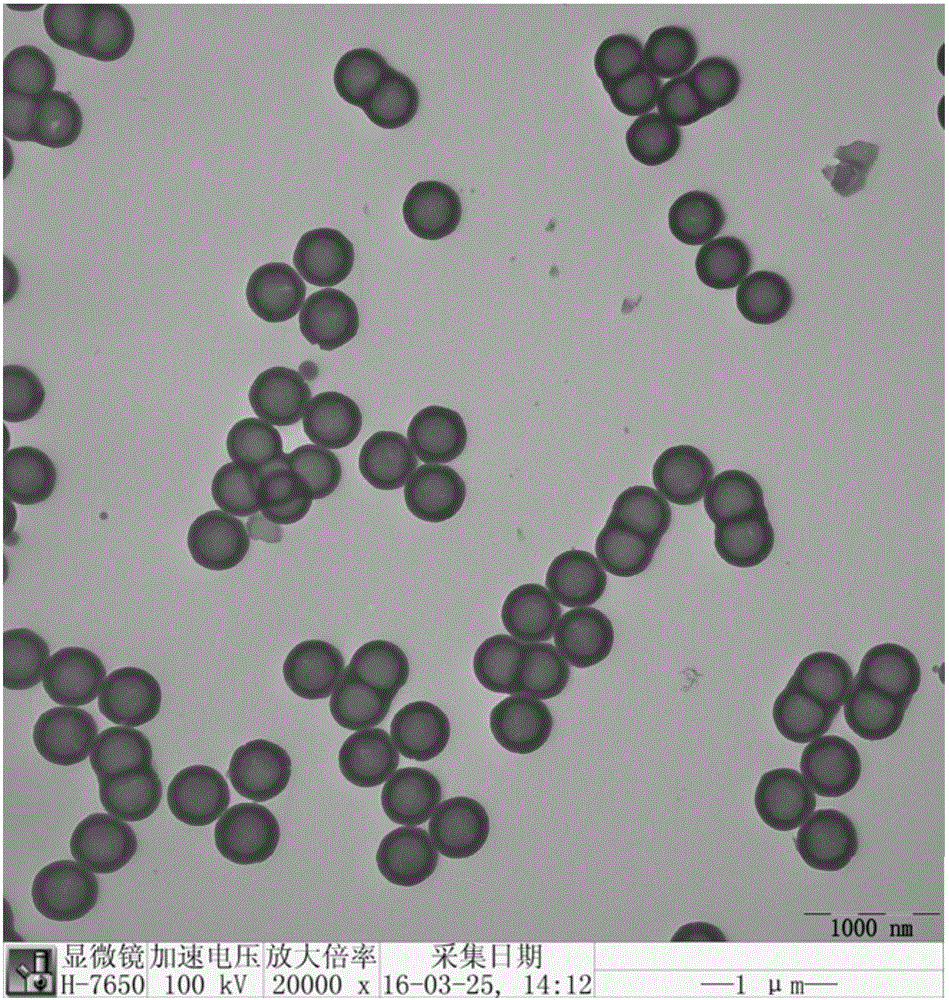

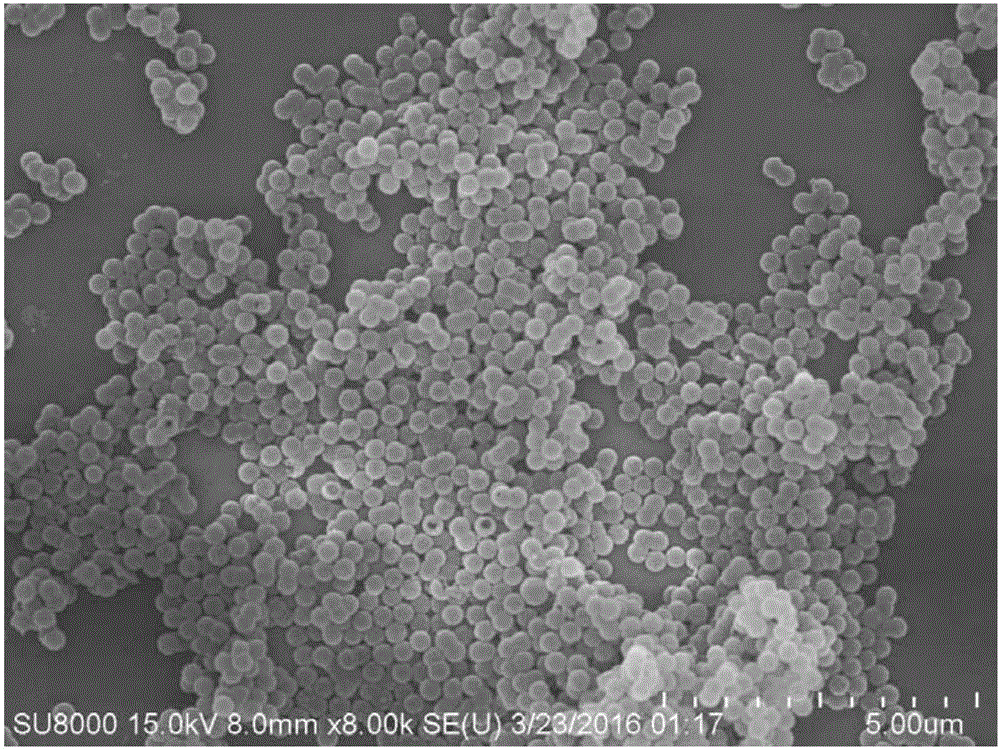

[0017] Embodiment 1: The preparation method of monodisperse hollow mesoporous silica nano-microspheres in this embodiment is carried out according to the following steps:

[0018] 1. Dissolve cetyltrimethylammonium bromide in ethanol aqueous solution, the ratio of cetyltrimethylammonium bromide to ethanol aqueous solution is 0.05-0.09g: 48mL, ethanol and ethanol in ethanol aqueous solution The volume ratio of water is 1:2, add polystyrene microspheres with a particle size of 200nm-700nm, the mass ratio of polystyrene microspheres to cetyltrimethylammonium bromide is 3:7, and then add ammonia water , the ratio of ammonia water to cetyltrimethylammonium bromide is 70-100mL: 7g, after stirring for 30min, add tetraethyl orthosilicate dropwise, the volume ratio of tetraethyl orthosilicate and ammonia water is 0.5-1.5: 8.5 , stirred and reacted for 18 hours, centrifuged, then washed 3 times with deionized water, washed 3 times with ethanol, and centrifuged;

[0019] 2. Dry the prec...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of ammonia water in step 1 is 25%-28%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the ratio of cetyltrimethylammonium bromide to ethanol in step 1 is 0.07g:48mL. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com