Resource comprehensive utilization for salty mud

A technology of resource utilization and salt mud, applied in the field of comprehensive utilization of salt mud, can solve the problems of increasing production cost, environmental pollution, large output and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

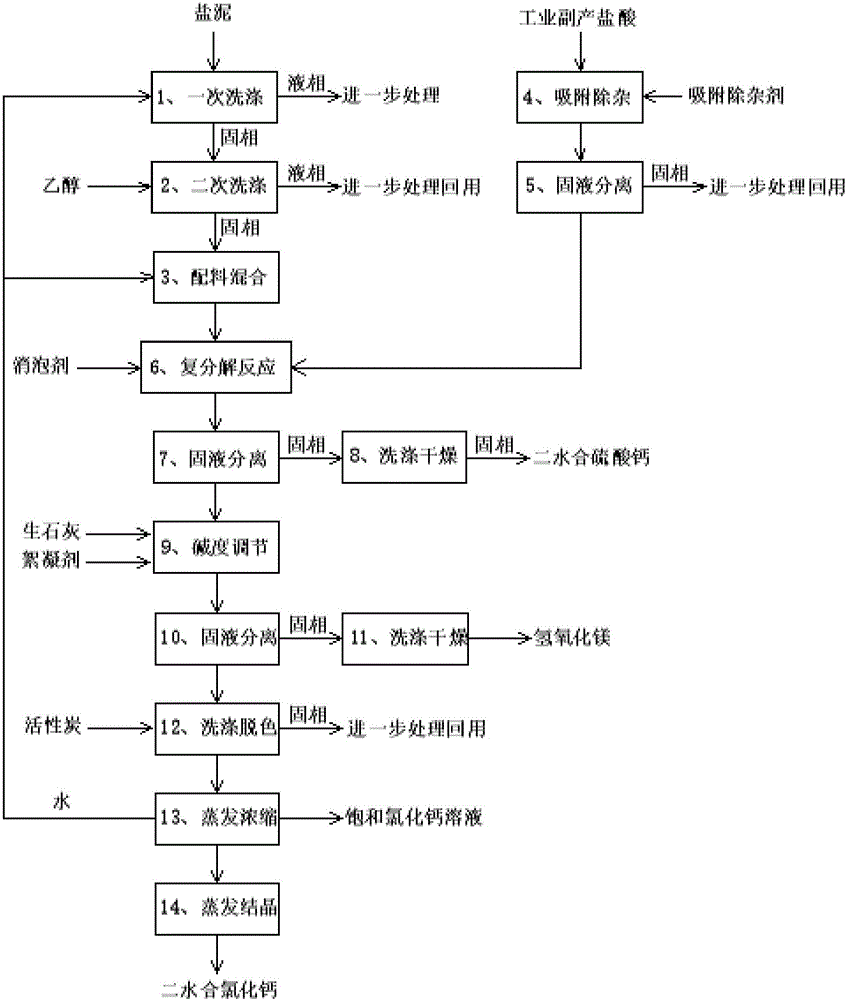

[0034] A method for resourceful comprehensive treatment of salt mud, which uses salt mud and industrial by-product hydrochloric acid as raw materials to prepare three types of products: calcium sulfate dihydrate, magnesium hydroxide, and calcium chloride dihydrate through reaction and separation

[0035] (1) One-time washing: the raw salt mud and water are mixed at a volume ratio of 1:2 for washing, washed once with water, and then vacuum drum dehydrated.

[0036] (2) Second washing: After the first washing and dehydration, the salt mud and ethanol are mixed at a volume ratio of 1:1 for the second washing, and the sub-water is washed once, and then the plate and frame filter is used to remove the ethanol, and the ethanol is further collected for reuse.

[0037] (3) Mixing of ingredients: Add the salt mud and water obtained in the previous step into the reactor at a volume ratio of 1:1 for ingredient mixing.

[0038] (4) Adsorption and impurity removal: add 3% macroporous adsor...

Embodiment approach 2

[0050] A comprehensive resource utilization method for salt mud, which uses salt mud and industrial by-product hydrochloric acid as raw materials to prepare three types of products: calcium sulfate dihydrate, magnesium hydroxide, and calcium chloride dihydrate through reaction and separation

[0051] (1) One-time washing: The raw salt mud and water are mixed at a volume ratio of 1:2.5 for washing, washed twice with water, and then vacuum drum dehydrated.

[0052] (2) Second washing: After the first washing and dehydration, the salt mud and ethanol are mixed at a volume ratio of 1:1.2 for the second washing, and the sub-water is washed once, and then the ethanol is removed by plate and frame pressure filtration, and the ethanol is further collected for reuse.

[0053] (3) Batch mixing: Add the salt mud and water obtained in the previous step into the reactor at a volume ratio of 1:1.1 for batch mixing.

[0054] (4) Adsorption and impurity removal: add diatomite accounting for 2...

Embodiment approach 3

[0066] A resource comprehensive utilization method of salt mud uses salt mud and industrial by-product hydrochloric acid as raw materials to prepare three types of products: calcium sulfate dihydrate, magnesium hydroxide and calcium chloride dihydrate through reaction and separation.

[0067] (1) One-time washing: the raw salt mud and water are mixed at a volume ratio of 1:3 for washing, washed once with water, and then vacuum drum dehydrated.

[0068] (2) Secondary washing: After the primary washing and dehydration, the salt mud and ethanol are mixed at a volume ratio of 1:1.5 for secondary washing, and the secondary water is washed twice, and then the ethanol is removed by plate and frame pressure filtration, and the ethanol is further collected for reuse.

[0069] (3) Batch mixing: Add the salt mud and water obtained in the previous step into the reactor at a volume ratio of 1:1.2 for batch mixing.

[0070] (4) Adsorption and impurity removal: add 2% macroporous adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com