A kind of preparation method and application of ultra-high cross-linked layered microporous polymer

A microporous polymer and ultra-high cross-linking technology, applied in the field of materials science, can solve the problems of polyaniline instability, easy agglomeration volume, expansion, etc., achieve good rate performance and cycle performance, solve volume expansion, and high degree of crystallization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing an ultra-highly cross-linked layered microporous polymer, comprising the steps of:

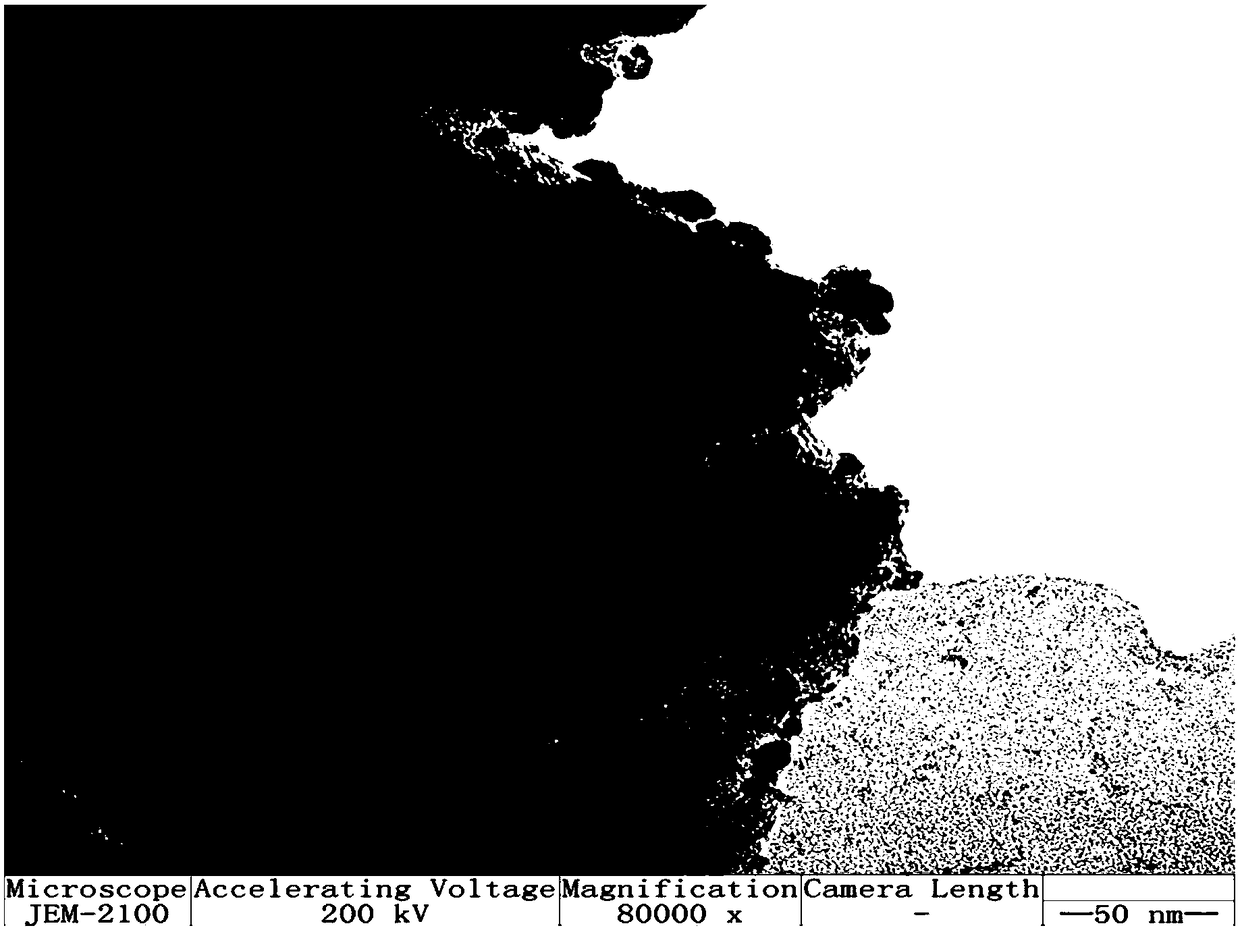

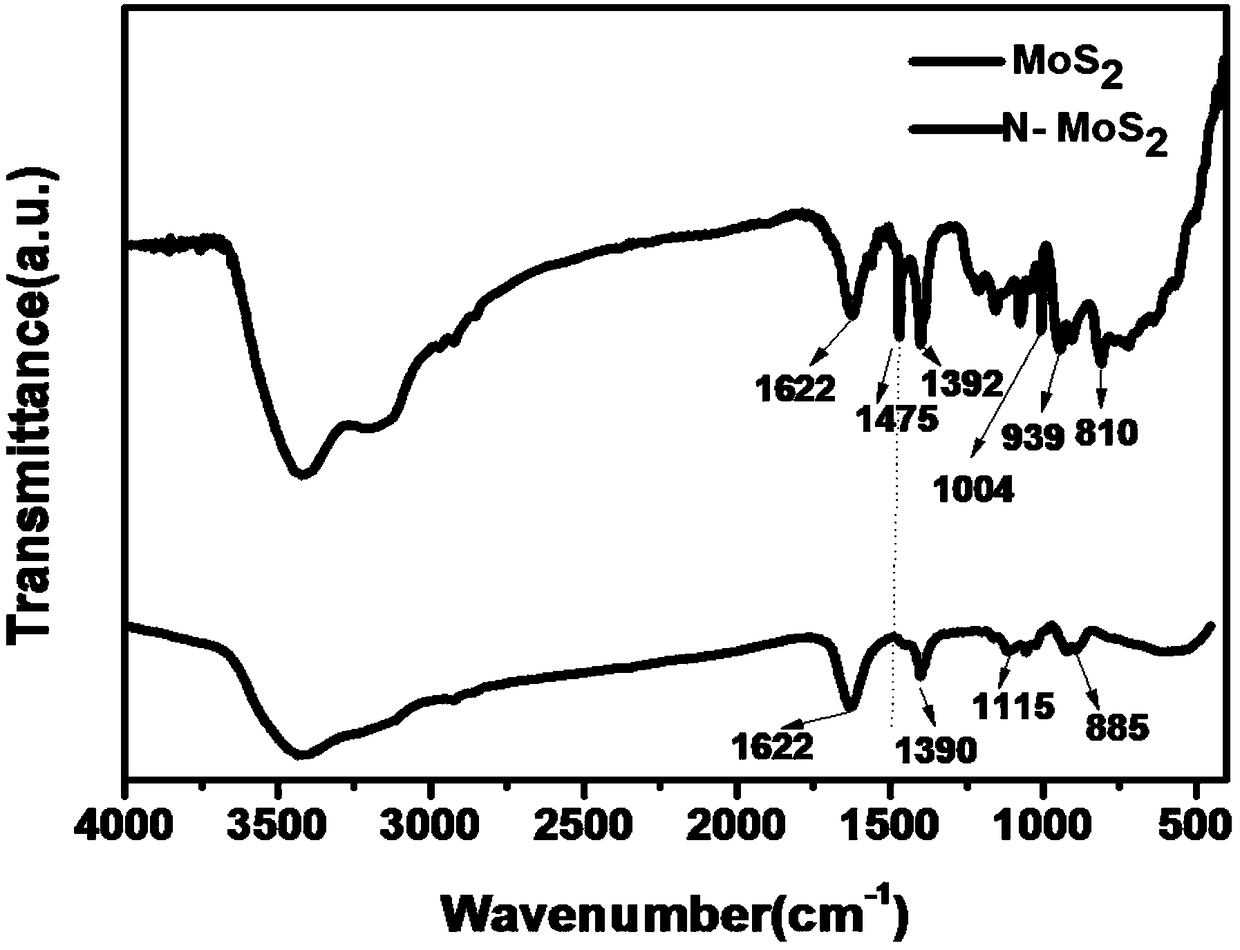

[0037] (1) Preparation of flaky molybdenum disulfide: at room temperature, add 15ml of deionized water, 15ml of ethanol, and 2ml of oleic acid into a 50ml beaker in turn, mix well and then slowly add 1.6g of sodium oleate and 1.0g of molybdenum NaCl, 0.9g thiourea, stirred for 5-10min, then ultrasonicated for 30-40min until the solution was completely clarified, adjusted the pH of the above solution to about 1.0 with the prepared 2.0M hydrochloric acid, the solution gradually changed from milky white to dark green, and finally turns black. The solution prepared above was moved into a 50ml polytetrafluoroethylene-lined stainless steel hydrothermal kettle, reacted at 180 degrees Celsius for 24 hours, cooled to room temperature naturally, filtered, washed four times with deionized water and pure ethanol, and the The filtered product was vacuum-dried at 60°C for 8 ho...

Embodiment 2

[0044] A method for preparing an ultra-highly cross-linked layered microporous polymer, specifically comprising the steps of:

[0045] (1) Preparation of flaky molybdenum disulfide: at room temperature, add 15ml of deionized water, 15ml of ethanol, and 2ml of oleic acid into a 50ml beaker in turn, mix well and then slowly add 1.6g of sodium oleate and 1.0g of molybdenum NaCl, 0.9g thiourea, stirred for 5-10min, then ultrasonicated for 30-40min until the solution was completely clarified, adjusted the pH of the above solution to about 1.0 with the prepared 2.0M hydrochloric acid, the solution gradually changed from milky white to dark green, and finally turns black. The solution prepared above was moved into a 50ml polytetrafluoroethylene-lined stainless steel hydrothermal kettle, reacted at 180 degrees Celsius for 24 hours, cooled to room temperature naturally, filtered, washed four times with deionized water and pure ethanol, and the The filtered product was vacuum-dried at ...

Embodiment 3

[0052] A method for preparing an ultra-highly cross-linked layered microporous polymer, specifically comprising the steps of:

[0053] (1) Preparation of flaky molybdenum disulfide: at room temperature, add 15ml of deionized water, 15ml of ethanol, and 2ml of oleic acid into a 50ml beaker in turn, mix well and then slowly add 1.6g of sodium oleate and 1.0g of molybdenum NaCl, 0.9g thiourea, stirred for 5-10min, then ultrasonicated for 30-40min until the solution was completely clarified, adjusted the pH of the above solution to about 1.0 with the prepared 2.0M hydrochloric acid, the solution gradually changed from milky white to dark green, and finally turns black. The solution prepared above was moved into a 50ml polytetrafluoroethylene-lined stainless steel hydrothermal kettle, reacted at 180 degrees Celsius for 24 hours, cooled to room temperature naturally, filtered, washed four times with deionized water and pure ethanol, and the The filtered product was vacuum-dried at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com