Cold and high temperature resistant PVC cable material

A high temperature resistant, cable material technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as environmental and human health damage, and achieve safe electricity consumption, good stability, and good thermal capacitance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

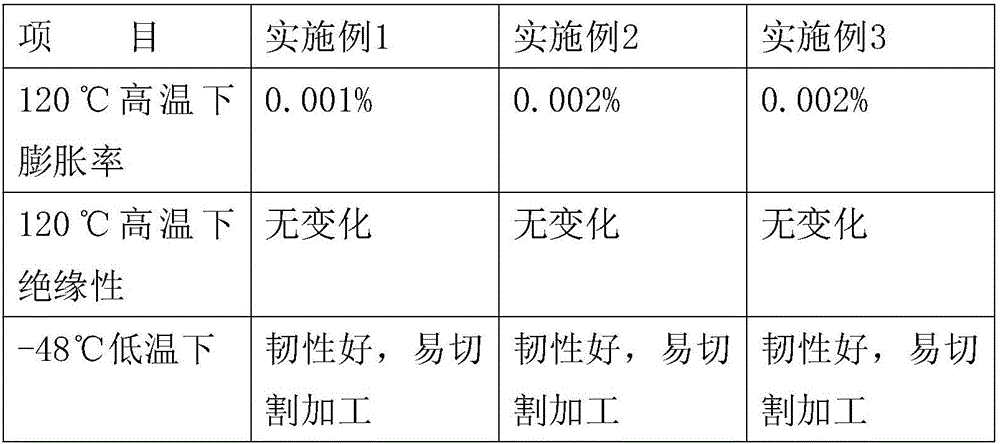

Examples

Embodiment 1

[0016] A cold-resistant and high-temperature-resistant PVC cable material, made of the following raw materials in parts by weight: 58 parts of polyvinyl chloride, 15 parts of high-density polypropylene, 4 parts of potassium sulfate, 4 parts of trioctyl trimellitate, calcium stearate 4 parts, 10 parts of malt oil, 10 parts of castor oil, 24 parts of calcium carbonate, 2 parts of bisphenol A, 15 parts of calcium hydroxide, 15 parts of potassium hydrogen phthalate, 6 parts of p-phenylenediamine, 18 parts of modified filler share;

[0017] The modified filler is made of the following raw materials in parts by weight: 7 parts of propylene glycol fatty acid ester, 7 parts of nano-alumina, 7 parts of epoxy resin, 18 parts of heptadecanoic acid, glyceryl laurate polyoxyethylene ether 18 parts, calcined clay 8 parts, lauryl trimethyl ammonium salt 6 parts, polyethylene terephthalate 6 parts, zirconia 7 parts, granite 7 parts, magnet 7 parts, methyl methacrylate 12 parts, 14 parts of x...

Embodiment 2

[0023] A cold-resistant and high-temperature-resistant PVC cable material, made of the following raw materials in parts by weight: 52 parts of polyvinyl chloride, 12 parts of high-density polypropylene, 3 parts of potassium sulfate, 3 parts of trioctyl trimellitate, calcium stearate 3 parts, 7.5 parts of malt oil, 7.5 parts of castor oil, 21 parts of calcium carbonate, 2 parts of bisphenol A, 10 parts of calcium hydroxide, 10 parts of potassium hydrogen phthalate, 4 parts of p-phenylenediamine, 15 parts of modified filler share;

[0024] The modified filler is made of the following raw materials in parts by weight: 5 parts of propylene glycol fatty acid ester, 5 parts of nano-alumina, 5 parts of epoxy resin, 13 parts of heptadecanoic acid, glyceryl laurate polyoxyethylene ether 13 parts, calcined clay 6 parts, lauryl trimethyl ammonium salt 4 parts, polyethylene terephthalate 4 parts, zirconia 7 parts, granite 7 parts, magnet 7 parts, methyl methacrylate 9 parts, 11 parts of ...

Embodiment 3

[0030] A cold-resistant and high-temperature resistant PVC cable material, made of the following raw materials in parts by weight: 65 parts of polyvinyl chloride, 18 parts of high-density polypropylene, 6 parts of potassium sulfate, 6 parts of trioctyl trimellitate, calcium stearate 6 parts, 13.5 parts of malt oil, 13.5 parts of castor oil, 27.5 parts of calcium carbonate, 3 parts of bisphenol A, 22 parts of calcium hydroxide, 22 parts of potassium hydrogen phthalate, 8 parts of p-phenylenediamine, 22 parts of modified filler share;

[0031] The modified filler is made of the following raw materials in parts by weight: 9 parts of propylene glycol fatty acid ester, 9 parts of nano-alumina, 9 parts of epoxy resin, 23 parts of heptadecanoic acid, glyceryl laurate polyoxyethylene ether 23 parts, calcined clay 9 parts, lauryl trimethyl ammonium salt 8 parts, polyethylene terephthalate 9 parts, zirconia 8 parts, granite 8 parts, magnet 8 parts, methyl methacrylate 16 parts, 16 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com