Anti-corrosion sampler and manufacturing method thereof

A sampler and corrosion-resistant technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of non-compliance with environmental protection requirements, inconvenient use, high material cost, long service life, non-corrosion, surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

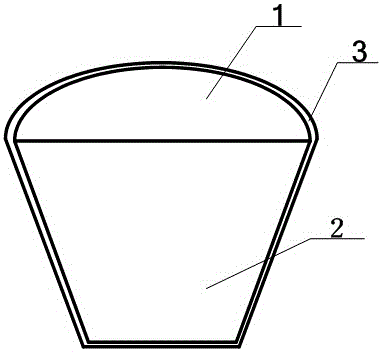

Image

Examples

Embodiment 1

[0049] A corrosion-resistant sampler, which is made up of the raw materials of the following components:

[0050] The percentage by weight of each component of the rod body of a corrosion-resistant sampler in this embodiment is as follows: Si: 0.40%, Mg: 0.64%, Cu: 0.02%, Fe: 0.23%, Sr: 0.03%, La: 0.14%, Nd: 0.18%, Zn: 0.03%, Ti: 0.05%, and the rest is Al.

[0051] Anti-corrosion paint group water-based epoxy emulsion 41-50 parts, dispersant 0.7-0.9 parts, defoamer 0.5-0.7 parts, leveling agent 0.5-0.7 parts, magnesium powder 10-25 parts, ultra-fine zinc phosphate powder 20-40 parts parts, 3 to 7 parts of dicumyl hydroperoxide, and 3 to 7 parts of deionized water; the water-based epoxy emulsion is composed of the following groups of raw materials: 400 to 450 parts of ECN9699 cresol formaldehyde epoxy resin, anion ring 18-25 parts of oxygen-based surfactant, 300-360 parts of deionized water.

[0052] Among them, the dispersant is preferably BYK191; the defoamer is preferably ...

Embodiment 2

[0054] In a preferred version, a corrosion-resistant sampler is made up of the raw materials of the following components:

[0055] Sampler: Si: 0.44%, Mg: 0.66%, Cu: 0.02%, Fe: 0.25%, Sr: 0.02%, La: 0.14%, Nd: 0.18%, Zn: 0.05%, Ti: 0.02%, and the rest are Al.

[0056] Anti-corrosion paint: 45 parts of water-based epoxy emulsion, 0.8 parts of dispersant, 0.6 parts of defoamer, 0.6 parts of leveling agent, 20 parts of magnesium powder, 35 parts of zinc powder, 5.5 parts of high methyl etherified melamine resin, 5.5 parts of deionized water The water-based epoxy emulsion is made up of the following groups of raw materials: 420 parts of ECN9699 cresol-formaldehyde epoxy resin, 20 parts of anionic epoxy-based surfactants, and 357 parts of deionized water.

Embodiment 3

[0058] In a preferred version, the anionic epoxy-based surfactant is made up of the raw materials of the following components:

[0059] 400 parts of GT6097 epoxy resin, 45 parts of propylene glycol methyl ether, 46.5 parts of p-aminobenzenesulfonic acid, 25.5 parts of DMEA, and 63 parts of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com