Yangpaopao aerobic detergent gel

A gel, alcohol polyoxyethylene ether sodium sulfate technology, applied in the field of daily chemicals, can solve the problems of increased environmental load, poor water solubility at room temperature, and reduced fabric color and hand feel, and achieves long shelf life, stable properties, and deodorization. The effect of strong dirt ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

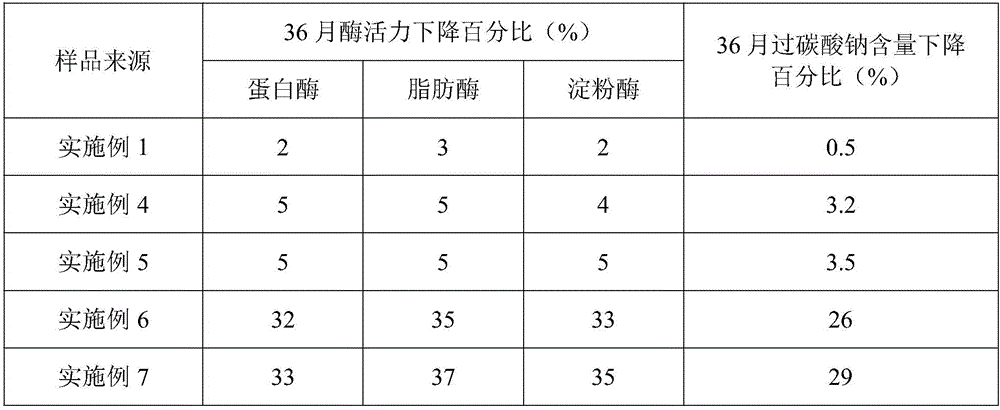

Examples

Embodiment 1

[0019] Example 1: Preparation of Aerobic Laundry Gel

[0020] Raw material weight ratio:

[0021] Surfactant Fatty Alcohol Ethoxylate Sodium Sulfate, 50 parts; Stain Dissolver Ethylene Glycol, 6 parts; Protease, 2 parts; Lipase, 2 parts; Amylase, 2 parts; Water Softener, Sodium Polyphosphate, 5 parts; active oxygen functional additive sodium percarbonate, 7 parts; lauric acid, 10 parts; oleic acid, 10 parts; also includes preservatives methyl paraben and ethyl paraben, a total of 7 parts, methyl paraben The ratio by weight to ethyl paraben is 6:1.

[0022] Preparation:

[0023] Step S1, uniformly mixing the surfactant, stain dissolving agent, lauric acid, oleic acid and preservative;

[0024] Step S2, adding water softener and active oxygen functional additive while stirring slowly;

[0025] Step S3, adding protease, lipase and amylase while stirring slowly, subpackaging and packaging.

Embodiment 2

[0026] Embodiment 2: the preparation of aerobic laundry gel

[0027] Raw material weight ratio:

[0028] Surfactant Sodium Alcohol Ethoxylate Sulfate, 45 parts; Stain Dissolver Ethylene Glycol, 5 parts; Protease, 1 part; Lipase, 1 part; Amylase, 1 part; Water Softener, Sodium Polyphosphate, 4 parts; active oxygen functional additive sodium percarbonate, 6 parts; lauric acid, 5 parts; oleic acid, 5 parts; also includes preservatives methyl paraben and ethyl paraben, a total of 6 parts, methyl paraben The ratio by weight to ethyl paraben is 5:1.

[0029] Preparation:

[0030] Step S1, uniformly mixing the surfactant, stain dissolving agent, lauric acid, oleic acid and preservative;

[0031] Step S2, adding water softener and active oxygen functional additive while stirring slowly;

[0032] Step S3, adding protease, lipase and amylase while stirring slowly, subpackaging and packaging.

Embodiment 3

[0033] Embodiment 3: the preparation of aerobic laundry gel

[0034] Raw material weight ratio:

[0035] Surfactant Sodium Alcohol Ethoxylate Sulfate, 55 parts; Stain Dissolver Ethylene Glycol, 7 parts; Protease, 3 parts; Lipase, 3 parts; Amylase, 3 parts; Water Softener, Sodium Polyphosphate, 6 parts; active oxygen functional additive sodium percarbonate, 8 parts; lauric acid, 15 parts; oleic acid, 15 parts; also includes preservatives methylparaben and ethylparaben, a total of 8 parts, methylparaben The ratio by weight to ethyl paraben is 7:1.

[0036] Preparation:

[0037] Step S1, uniformly mixing the surfactant, stain dissolving agent, lauric acid, oleic acid and preservative;

[0038] Step S2, adding water softener and active oxygen functional additive while stirring slowly;

[0039] Step S3, adding protease, lipase and amylase while stirring slowly, subpackaging and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com