Semipermeable membrane support body and preparing method therefor

A semi-permeable membrane and support technology, applied in the field of semi-permeable membrane support and its preparation, can solve the problems of penetration and achieve the effect of preventing penetration and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

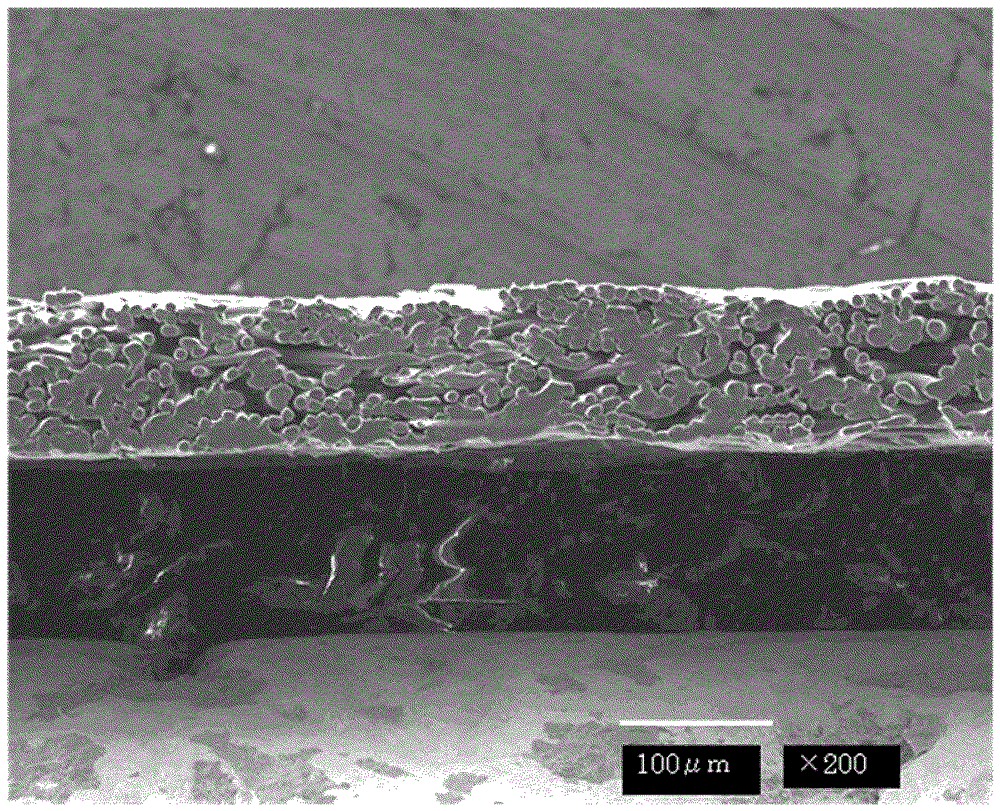

[0070] The method for producing the semipermeable membrane support of the present invention will be described. After the semipermeable membrane support body of the present invention prepares a sheet by a wet sheet-making method, the sheet is hot-pressed by a hot roller.

[0071] In the wet papermaking method, at least the main synthetic fiber and the binder synthetic fiber are uniformly dispersed in water, and then the final fiber concentration is adjusted to 0.01~0.50% by mass after sieving (removing foreign matter, lumps, etc.) The slurry was taken out with a paper machine to obtain wet paper. In order to make the dispersibility of the fiber uniform, dispersants, defoamers, hydrophilic agents, antistatic agents, polymer adhesives, release agents, antibacterial agents, bactericides and other drugs can also be added in the process.

[0072] As the papermaking method, for example, papermaking methods such as fourdrinier, cylinder, and inclined wire can be used. A papermaking ...

Embodiment 1-1

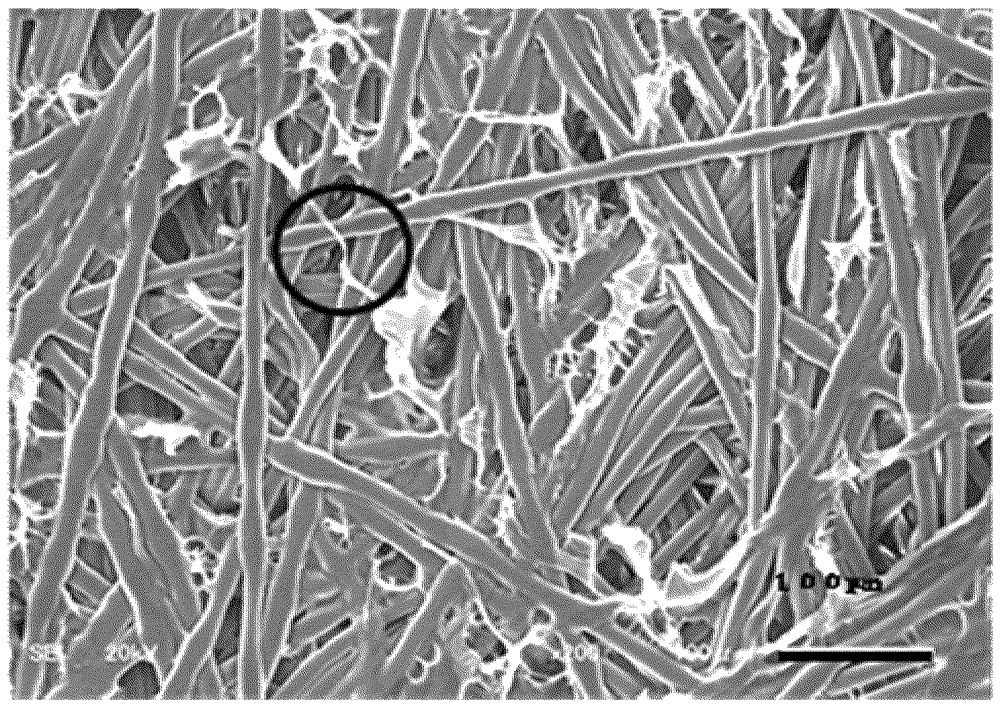

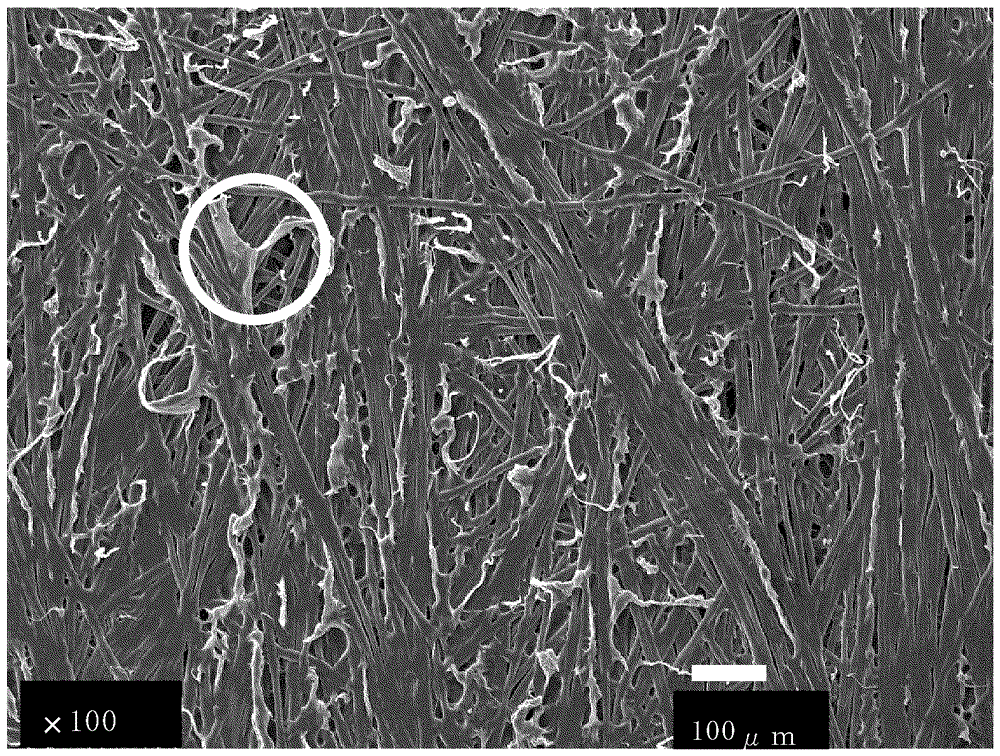

[0087] Main synthetic fiber (stretched polyester fiber, diameter 12.5 μm, fiber length 5 mm), binder synthetic fiber (undrawn polyester fiber, diameter 10.5 μm, The fiber length is 5 mm and the melting point is 260°C) is mixed and dispersed in water, and wet paper is formed with a cylinder paper machine, and then hot-pressed and dried with a Yankee dryer with a surface temperature of 130°C to obtain the weight per unit area 80g / m 2 Sheet.

[0088] Using the first-stage calendering device combined with a heated metal roll and a resin roll, the obtained sheet is hot-pressed under the conditions of a surface temperature of the heated metal roll of 215°C, a pressure of 1000 N / cm, and a processing speed of 30 m / min. Processing, using a second-stage calendering device combining a resin roll and a heated metal roll in such a way that the surface of the sheet that has been in contact with the heated metal roll is continuously in contact with the resin roll, the surface temperature of...

Embodiment 1-2

[0090] A semipermeable membrane support was obtained in the same manner as in Example 1-1, except that the temperatures of the first-stage heating metal roll and the second-stage heating metal roll were changed to 220°C and 220°C, respectively. In addition, let the surface which contacts a heating metal roll first be a coating surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com