Method for manufacturing a charge dissipative surface layer

A surface layer, charge technology, applied in coatings, circuits, conductive materials, etc., can solve problems such as product difficulties with charge dissipation surface characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment IE

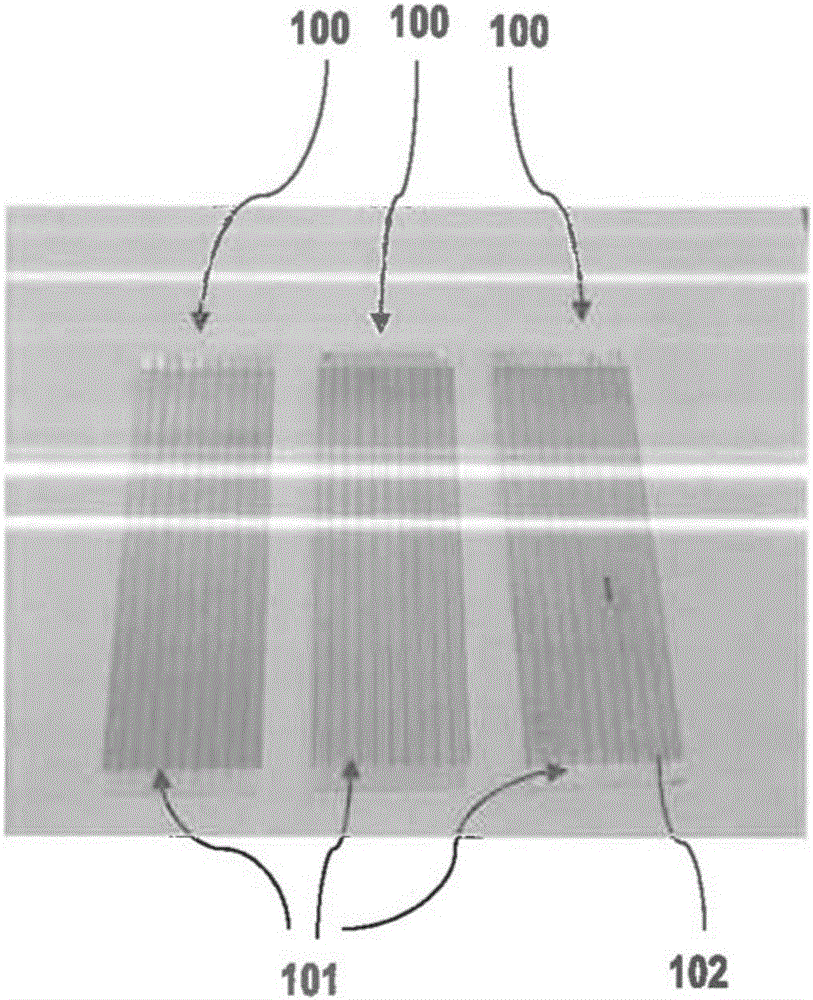

[0109] 50 standard FCCs of different sizes (105mm, 205mm) with the same standard as CE were treated with the following ion beam process:

[0110] Equipment: KVARC-700 high vacuum with rotating drum (0.5m wide, stainless steel)

[0111] Process conditions:

[0112] - Starting vacuum is about 3×10 -3 Pa; vacuum baked at 35°C for 2 hours before processing

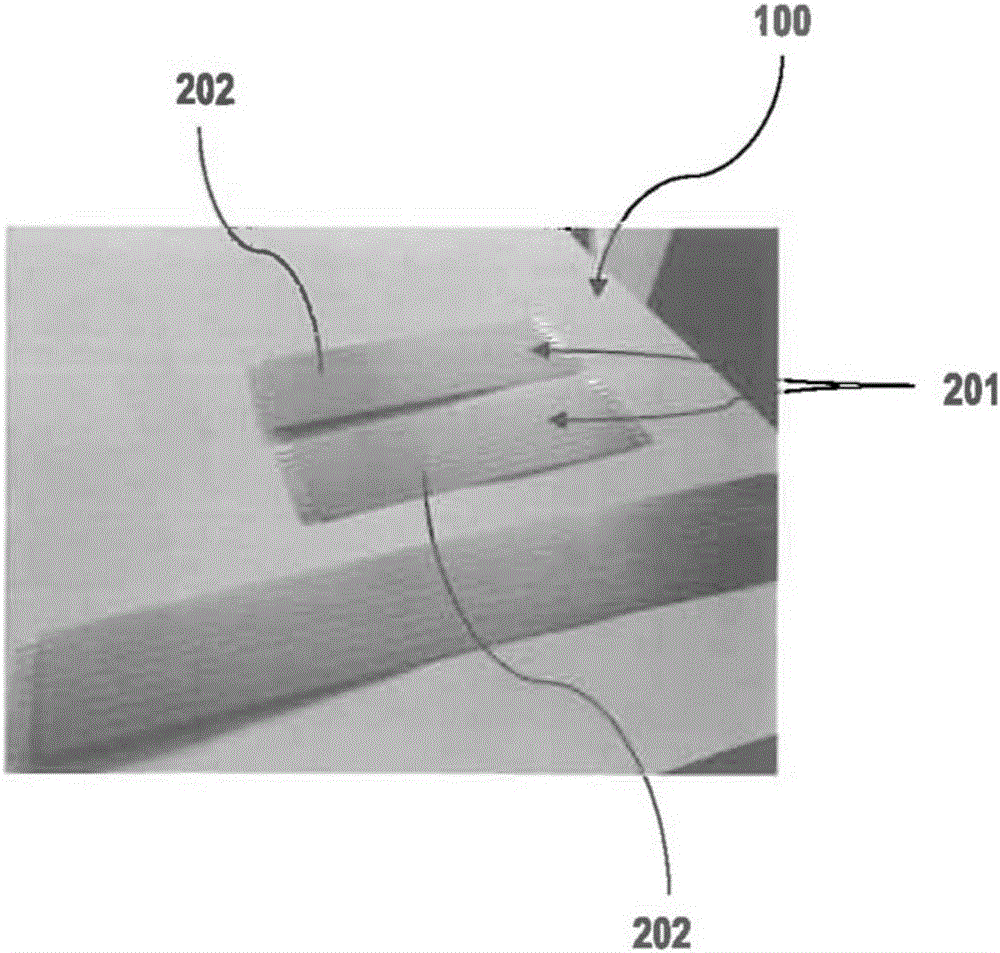

[0113] - using argon (92 volume %) and acetylene (C 2 h 2 , 8 vol%) mixture of linear ion beam sources

[0114] - Ion beam energy 2.5-3keV; ion beam current 195mA; bias on drum 150V

[0115] -Temperature <65°C; treatment duration 16 minutes

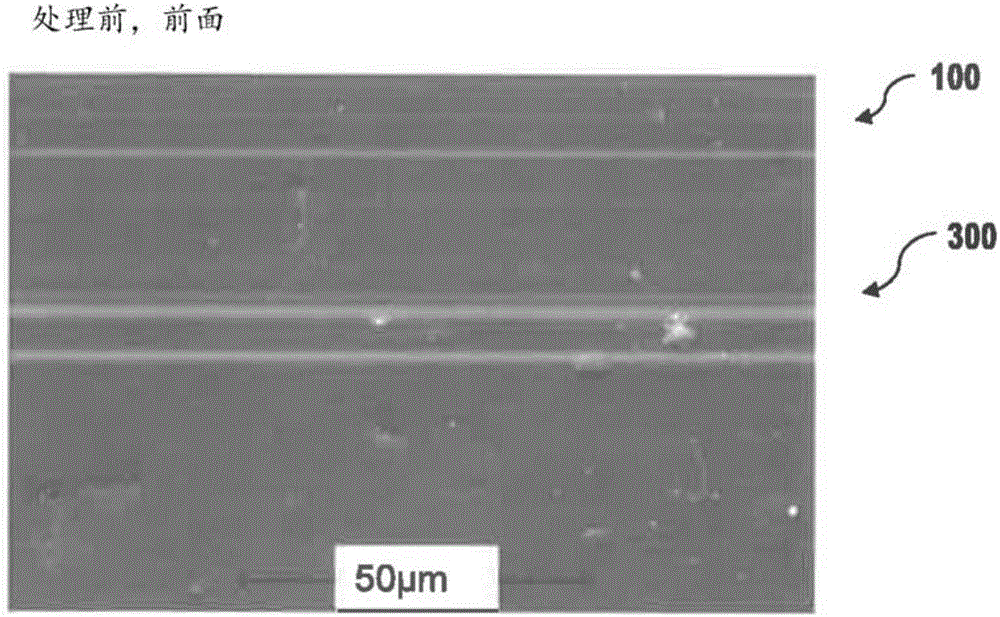

[0116] - Treat the second surface in a separate process using the same process conditions

[0117] -Fix the FCC to the drum and mask the copper ends and adjacent edges of the Kapton surface with polyimide pressure sensitive tape (CGSTAPE-8358, 1 inch) with silicone adhesive

[0118] Both sides of 50 FCCs were processed in several rounds of the process.

[0119] All bulk and surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com