Pure barley pregnant sow feed and production method thereof

A technology for pregnant sows and feed, applied in the field of pure barley-type pregnant sow feed and its production, can solve the problems of damaging the normal shape and function of intestinal mucosa, reducing the intestinal absorption capacity of nutrients, and low feed conversion efficiency, etc. Achieve good reproductive performance, reduce feed costs, and ensure normal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

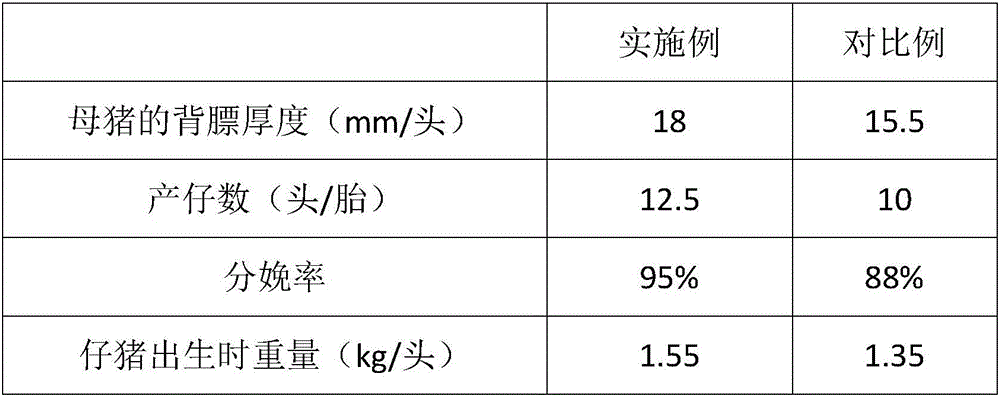

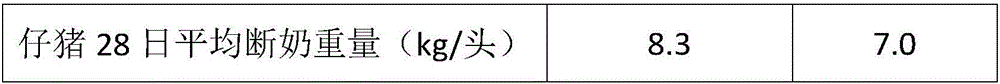

Examples

Embodiment 1

[0024] A pure barley-type feed for pregnant sows, which is composed of the following raw materials: 38.83kg of peeled naked barley, 15kg of hulled barley, 8kg of puffed soybean meal, 10kg of wheat bran, 10kg of wheat subflour, 6kg of sugar beet granule meal, 3kg of No. 3 flour, corn Distiller's grains (DDGS) 3kg, soybean oil 2kg, multivitamins 0.2kg, mineral elements 0.3kg, β-glucanase 0.02kg, xylanase 0.01kg, compound enzyme 0.04kg, 70% L-lysine hydrochloride 0.40kg, 98% L-threonine 0.1kg, 98.5% L-tryptophan 0.02kg, 60% choline chloride 0.15kg, baking soda 0.05kg, salt 0.38kg, stone powder 1kg and calcium monohydrogen phosphate 1.5kg .

Embodiment 2

[0026] A pure barley-type feed for pregnant sows, which is composed of the following raw materials: 47.83kg of peeled naked barley, 15kg of hulled barley, 6kg of puffed soybean meal, 5kg of wheat bran, 5kg of wheat subflour, 6kg of sugar beet granule meal, 5kg of No. 3 flour, corn Distiller's grains (DDGS) 3kg, soybean oil 3kg, multivitamins 0.2kg, mineral elements 0.3kg, β-glucanase 0.02kg, xylanase 0.01kg, compound enzyme 0.04kg, 70% L-lysine hydrochloride 0.40kg, 98% L-threonine 0.1kg, 98.5% L-tryptophan 0.02kg, 60% choline chloride 0.15kg, baking soda 0.05kg, salt 0.38kg, stone powder 1kg and calcium monohydrogen phosphate 1.5kg .

Embodiment 3

[0028] A pure barley-type feed for pregnant sows, which is composed of the following raw materials: 42.83kg of peeled naked barley, 15kg of hulled barley, 7kg of puffed soybean meal, 6kg of wheat bran, 8kg of wheat subflour, 6kg of sugar beet granule meal, 5kg of No. 3 flour, corn Distiller's grains (DDGS) 3kg, soybean oil 3kg, multivitamins 0.2kg, mineral elements 0.3kg, β-glucanase 0.02kg, xylanase 0.01kg, compound enzyme 0.04kg, 70% L-lysine hydrochloride 0.40kg, 98% L-threonine 0.1kg, 98.5% L-tryptophan 0.02kg, 60% choline chloride 0.15kg, baking soda 0.05kg, salt 0.38kg, stone powder 1kg and calcium monohydrogen phosphate 1.5kg .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com