Petrochemical acidic tail gas treatment system

A technology of acid tail gas and treatment system, which is applied in the direction of gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of high investment, tail gas emission, environmental pollution, etc., and achieve the effect of reducing investment and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

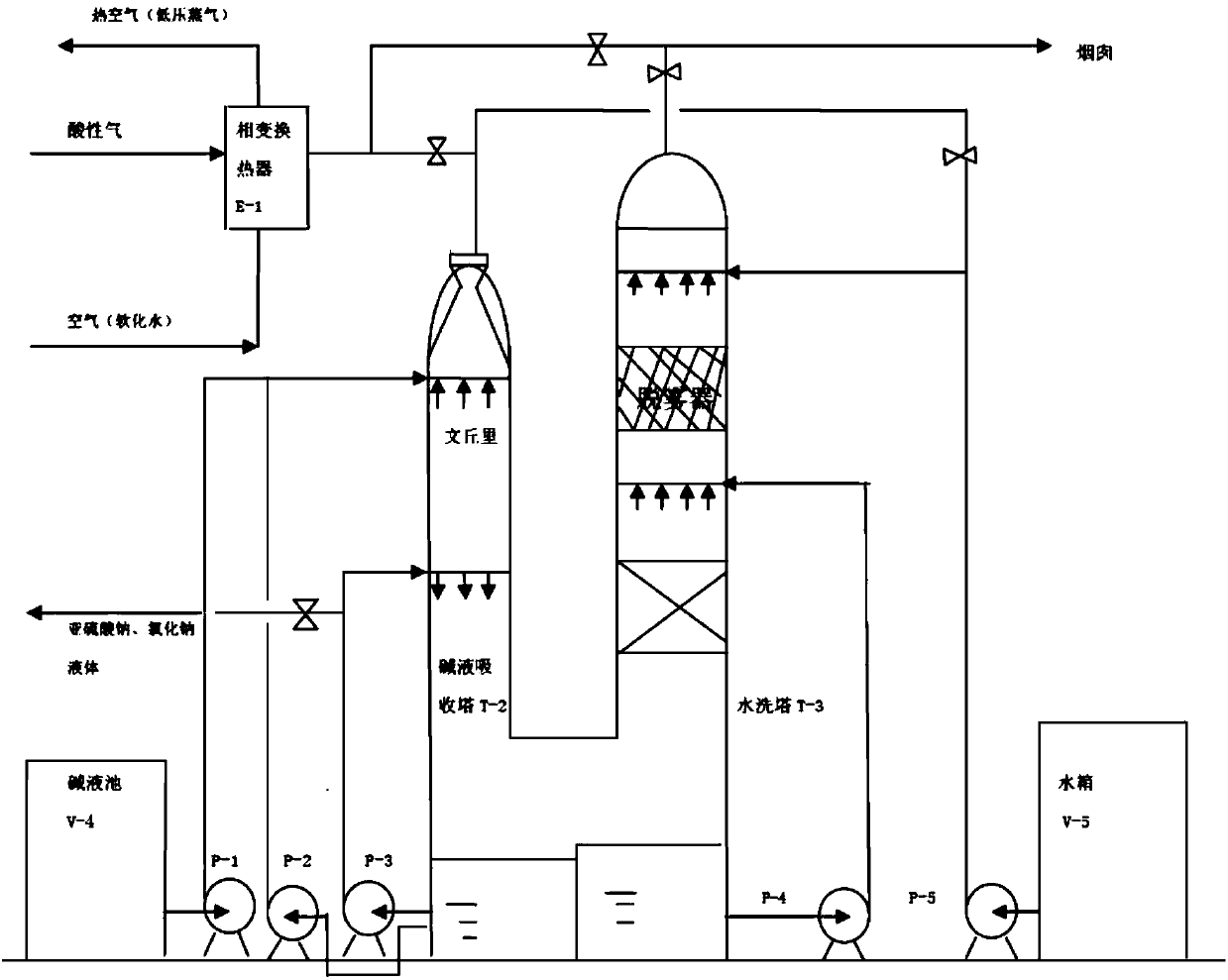

[0012] The petrochemical acid tail gas treatment system of the present invention, its preferred embodiment is:

[0013] Including heat exchanger, lye absorption tower, water washing tower, lye pool, lye pump, alkali washing liquid circulation pump, water washing liquid circulation pump, process water pump and water tank;

[0014] Described lye absorption tower links to each other with the bottom of water washing tower, and the bottom of described lye absorption tower is provided with alkali washing liquid storage area, and the bottom of described water washing tower is provided with water washing liquid storage area, and described alkali washing liquid storage area It is lower than the water washing liquid storage area, and the water washing liquid storage area is provided with an overflow port towards the alkaline washing liquid storage area;

[0015] The alkali washing liquid storage area is connected to the alkali liquid absorption tower through the alkali washing liquid ci...

specific Embodiment

[0068] Such as figure 1 As shown, the acid tail gas is the middle and high temperature exhaust gas containing chlorine and sulfur discharged from petrochemical and coal chemical production equipment, in which the content of hydrogen chloride is 0.3-0.5v%, the content of sulfur dioxide is 0.03-0.04v%, and the content of chlorine is 0.05-0.08v %. The tail gas containing chlorine and sulfur in the heat medium is heated to 80 degrees by the phase change heat exchanger E-1, and then enters from the top of the Venturi lye absorption tower 2, and the softened water in the cold medium is heat-exchanged to generate 0.4MPa steam. Sending device or Air for the instruments inside the device.

[0069] The lye pump P-1 extracts the NaOH aqueous solution with a mass fraction of 12% from the lye pool V-4 to the lye absorption tower T-2 bottom that contains sodium sulfite and sodium chloride and is transported by the alkali washing liquid circulation pump P-2. The liquid is mixed and sent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com