Novel high-performance waterproof roll and making method thereof

A waterproof membrane, high-performance technology, applied in the direction of chemical instruments and methods, coatings, building components, etc., can solve problems such as poor weather resistance, limit the application of membranes, and cannot meet the performance requirements of high-performance waterproof materials, and achieve expansion Application range, effect of optimizing waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

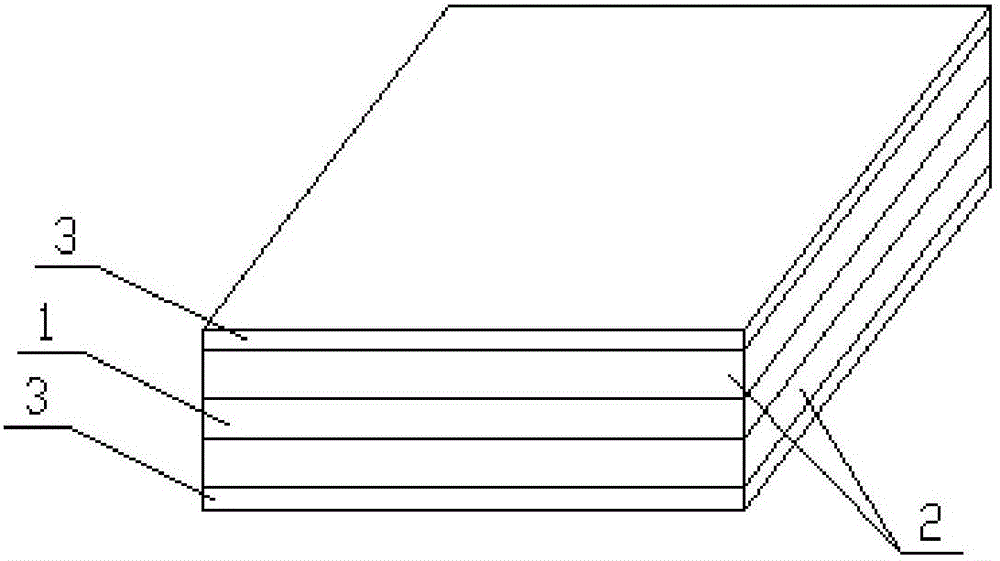

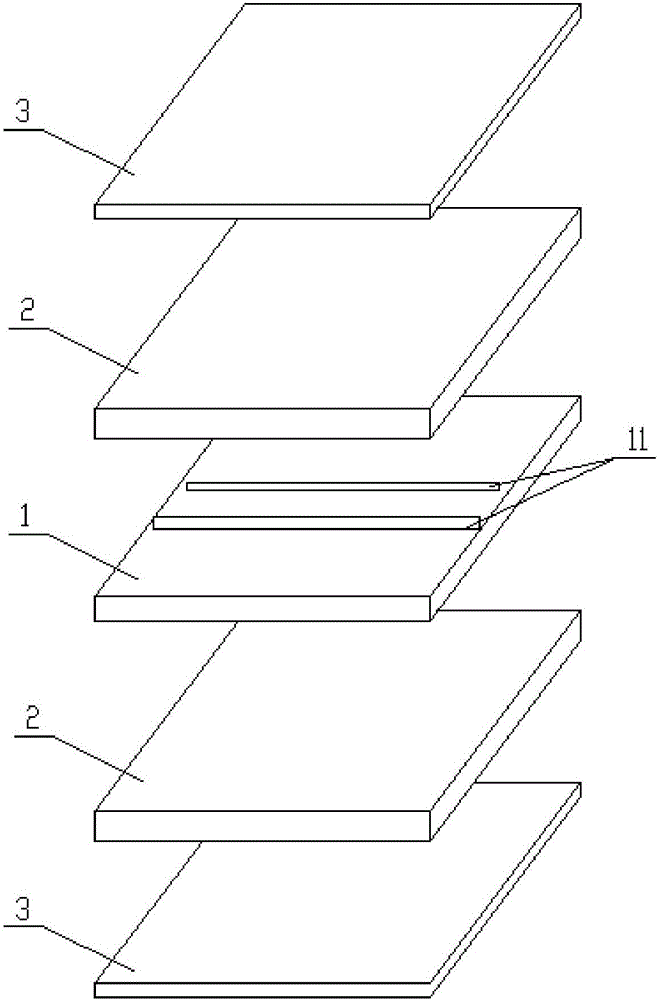

[0026] Such as figure 1 Shown, concrete technical scheme of the present invention is as follows:

[0027] A new type of high-performance waterproof membrane, including a base layer 1 and a modified layer 2; the base layer 1 is formed by coating a conductive nano-slurry on the surface of a base cloth, and the modified layer 2 is formed by using asphalt, modifiers, fillers, functional It is made by mixing functional film 3 and pre-dipping oil, and the functional film 3 is arranged on the surface of the modified layer 2.

[0028] The base cloth is made of polyester felt; the modified layer 2 is embedded with copper wires 11 .

[0029] The conductive nano-slurry is prepared by mixing resin, conductive nano-materials, additives, and co-solvents; calculated by weight fraction, the conductive nano-slurry is prepared according to the following formula:

[0030] Carbon nanotubes 2-5%, water-based acrylic resin 40-50%, conductive filler 10-30%, water 5-15%, ethylene glycol butyl ether...

Embodiment 2

[0039] Such as figure 1 Shown, concrete technical scheme of the present invention is as follows:

[0040] A new type of high-performance waterproof membrane, including a base layer 1 and a modified layer 2; the base layer 1 is formed by coating a conductive nano-slurry on the surface of a base cloth, and the modified layer 2 is formed by using asphalt, modifiers, fillers, functional It is made by mixing functional film 3 and pre-dipping oil, and the functional film 3 is arranged on the surface of the modified layer 2.

[0041] The base cloth is made of polyester felt; the modified layer 2 is embedded with copper wires.

[0042] The conductive nano-slurry is prepared by mixing resin, conductive nano-materials, additives, and co-solvents; calculated by weight fraction, the conductive nano-slurry is prepared according to the following formula:

[0043] Carbon nanotubes 2-5%, graphene 2-6%, water-based polyurethane resin 40-50%, conductive filler 8-30%, water 5-15%, ethylene gly...

Embodiment 3

[0052] A new type of high-performance waterproof membrane, including a base layer 1 and a modified layer 2; the base layer 1 is formed by coating a conductive nano-slurry on the surface of a base cloth, and the modified layer 2 is formed by using asphalt, modifiers, fillers, functional It is made by mixing functional film 3 and pre-dipping oil, and the functional film 3 is arranged on the surface of the modified layer 2.

[0053] The base cloth is made of polyester felt; the modified layer 2 is embedded with copper wires 11 .

[0054] The conductive nano-slurry is prepared by mixing resin, conductive nano-materials, additives, and co-solvents; calculated by weight fraction, the conductive nano-slurry is prepared according to the following formula:

[0055] Carbon nanotube 2-5%, graphene 2-6%, fullerene 2-4%, solvent-based acrylic resin 40-50%, conductive filler 8-35%, ethylene glycol butyl ether 5-20%, solvent Type additives (including leveling agent, defoamer, adhesion promo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com