A kind of preparation method and application of tempo block polymer

A technology of block polymers and materials, applied in the field of preparation of TEMPO-containing block polymers, can solve the problems of difficulty in achieving catalytic activity of supported catalysts, poor hydrophilicity of carriers, etc., achieve large load capacity, realize recycling and save energy The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

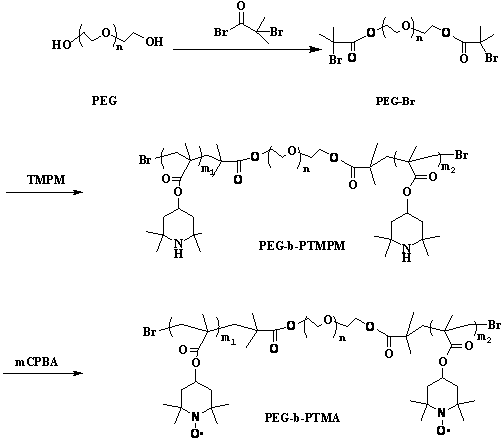

[0026] 1. Preparation of Block Polymer PEG-PTMA Containing TEMPO

[0027] (1) Dissolve 20g of PEG (molecular weight 20000, denoted as PEG20000) in 40mL CH 2 Cl 2 Add it into a 100mL three-neck flask equipped with a thermometer, magnetic stirring rotor, and constant pressure separatory funnel, then add 4.065mmol TEA, and put it in an ice bath; when the temperature of the reaction system drops to 0°C, 4.185mmol BiB and 20mL CH 2 Cl 2 The formed mixed solution was slowly added dropwise into the reaction kettle through a constant pressure separatory funnel, and the dropping time was 40 minutes; after the dropwise addition was completed, it was reacted at room temperature for 24 hours; 1mol / L hydrochloric acid and saturated sodium bicarbonate solution were added to the reaction solution , saturated sodium chloride solution, stirred and washed, separated after standing, added anhydrous magnesium sulfate to the organic phase to absorb excess water, precipitated with ether, filtere...

Embodiment 2

[0034] 1. Preparation of Block Polymer PEG-PTMA Containing TEMPO

[0035] (1) Dissolve 24g of PEG (molecular weight 6000, denoted as PEG6000) in 40mL CH 2 Cl 2 Add it into a 100mL three-neck flask equipped with a thermometer, magnetic stirring rotor, and constant pressure separatory funnel, then add 16.3mmol TEA, and put it in an ice bath; when the temperature of the reaction system drops to 0°C, 16.74mmol BiB and 20mL CH 2 Cl 2 The formed mixed solution was slowly added dropwise into the reaction kettle through a constant pressure separatory funnel, and the dropping time was 45 minutes; after the dropwise addition was completed, it was reacted at room temperature for 24 hours; , saturated sodium chloride solution, stirred and washed, separated after standing, added anhydrous magnesium sulfate to the organic phase to absorb excess water, precipitated with ether, filtered, and vacuum-dried the precipitate at 40°C for 12 hours to obtain a macromolecular trigger Agent PEG6000...

Embodiment 3

[0042] 1. Preparation of Block Polymer PEG-PTMA Containing TEMPO

[0043] (1) Dissolve 20g of PEG (molecular weight 4000, denoted as PEG4000) in 40mL CH 2 Cl 2 Add it into a 100mL three-neck flask equipped with a thermometer, magnetic stirring rotor, and constant pressure separatory funnel, then add 20.3mmol TEA, and put it in an ice bath; when the temperature of the reaction system drops to 0°C, 20.9mmol BiB and 20mL CH 2 Cl 2 The formed mixed solution was slowly added dropwise into the reaction kettle through a constant pressure separatory funnel, and the dropping time was 50 minutes; after the dropwise addition was completed, it was reacted at room temperature for 24 hours; , saturated sodium chloride solution, stirred and washed, separated after standing, added anhydrous magnesium sulfate to the organic phase to absorb excess water, precipitated with ether, filtered, and vacuum-dried the precipitate at 40°C for 12 hours to obtain a macromolecular trigger Agent PEG4000-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com