Method for preparing bacterial cellulose/NBSK (Northern Bleached Softwood Kraft) aerogel spheres under assistance of cation solution

A technology based on bacterial cellulose and cations, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as the collapse of spherical airgel structures, achieve the effect of reducing structure collapse and improving the production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

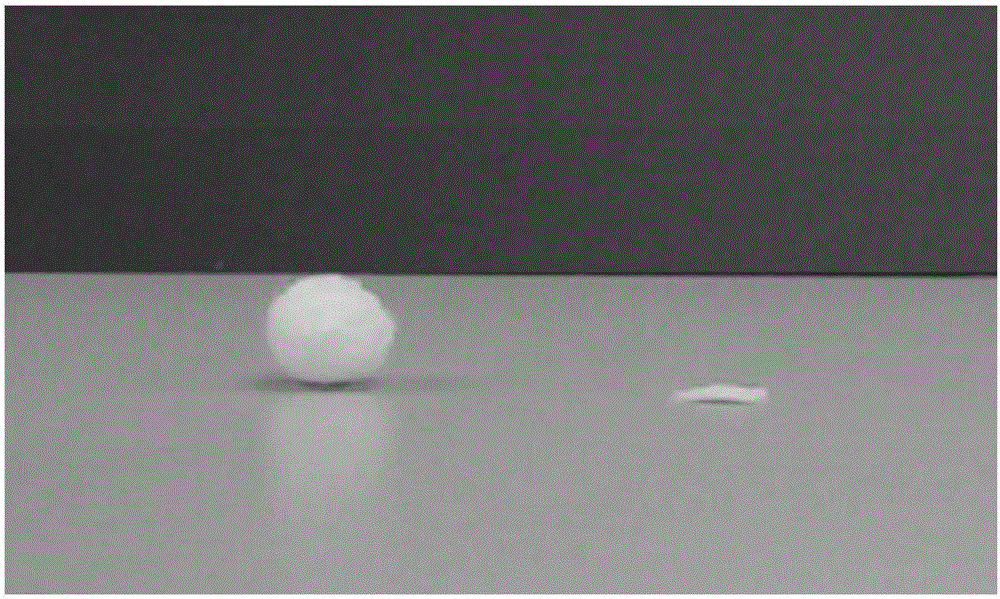

Image

Examples

Embodiment 1

[0038]Acetobacter xylinum was inoculated in 30mL of liquid seed medium (medium composition: fructose 50g / L, peptone 5g / L, yeast extract 5g / L, sodium monohydrogen phosphate 2.6g / L, anhydrous citric acid 1.15g / L L), cultured statically for 48 hours in an incubator at 32°C. Take a 250mL Erlenmeyer flask with a sponge stopper, add 1.25g NBSK fiber, 100mL liquid fermentation medium (the same composition as the seed medium), adjust the pH to 6.0 (the adjustment reagents are 0.1mol / L hydrochloric acid and 0.1mol / L Sodium hydroxide), sterilized at 121°C for 50min (198.64kPa). After the culture medium was cooled, 25 mL of Acetobacter xylinum seed liquid was added, and placed in a shaker with a rotation speed of 150 rpm and a temperature of 32 ° C for 72 hours to obtain bacterial cellulose / NBSK hydrogel balls. The prepared hydrogel spheres were treated with 0.1 mol / L sodium hydroxide solution in a shaker at a temperature of 80° C. and a rotation speed of 100 rpm. Rinse the hydrogel sp...

Embodiment 2

[0040] Acetobacter xylinum was inoculated in 30mL of liquid seed medium (medium composition: fructose 50g / L, peptone 5g / L, yeast extract 5g / L, sodium monohydrogen phosphate 2.6g / L, anhydrous citric acid 1.15g / L L), cultured statically for 48 hours in an incubator at 32°C. Take a 150mL Erlenmeyer flask with a sponge stopper, add 0.9g NBSK, 75mL liquid fermentation medium (the same composition as the seed medium), and adjust the pH value to 6.5 (the adjustment reagents are 0.1mol / L hydrochloric acid and 0.1mol / L Sodium hydroxide), sterilized at 121°C for 50min (198.64kPa). After the medium was cooled, 25 mL of Acetobacter xylinum seed liquid was added, and placed in a shaker with a rotation speed of 200 rpm and a temperature of 32 ° C for 72 hours to obtain bacterial cellulose / NBSK hydrogel balls. The prepared hydrogel spheres were treated with 0.1 mol / L sodium hydroxide solution in a shaker at a temperature of 80° C. and a rotation speed of 100 rpm. Rinse the hydrogel spheres...

Embodiment 3

[0042] Acetobacter xylinum was inoculated in 30mL of liquid seed medium (medium composition: fructose 50g / L, peptone 5g / L, yeast extract 5g / L, sodium monohydrogen phosphate 2.6g / L, anhydrous citric acid 1.15g / L L), cultured statically for 48 hours in an incubator at 32°C. Take a 250mL Erlenmeyer flask with a sponge stopper, add 1.25g NBSK fiber, 100mL liquid fermentation medium (the same composition as the seed medium), and adjust the pH value to 7.0 (adjusting reagents are 0.1mol / L hydrochloric acid and 0.1mol / L Sodium hydroxide), sterilized at 121°C for 50min (198.64kPa). After the culture medium was cooled, 25 mL of Acetobacter xylinum seed liquid was added, and placed in a shaker with a rotation speed of 150 rpm and a temperature of 32 ° C for 72 hours to obtain bacterial cellulose / NBSK hydrogel balls. The prepared hydrogel spheres were treated with 0.1 mol / L sodium hydroxide solution in a shaker at a temperature of 80° C. and a rotation speed of 100 rpm. Rinse the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com