A cationic solution-assisted method for preparing bacterial cellulose/nbsk airgel balls

A technology of bacterial cellulose and cations, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve problems such as the collapse of spherical airgel structures, achieve the effect of reducing structure collapse and increasing production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

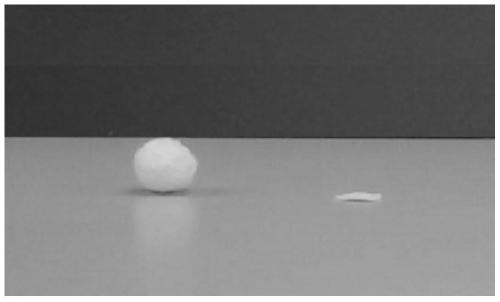

Image

Examples

Embodiment 1

[0038]Acetobacter xylinum was inoculated in 30mL of liquid seed medium (medium composition: fructose 50g / L, peptone 5g / L, yeast extract 5g / L, sodium monohydrogen phosphate 2.6g / L, anhydrous citric acid 1.15g / L L), cultured statically for 48 hours in an incubator at 32°C. Take a 250mL Erlenmeyer flask with a sponge stopper, add 1.25g NBSK fiber, 100mL liquid fermentation medium (the same composition as the seed medium), adjust the pH to 6.0 (the adjustment reagents are 0.1mol / L hydrochloric acid and 0.1mol / L Sodium hydroxide), sterilized at 121°C for 50min (198.64kPa). After the culture medium was cooled, 25 mL of Acetobacter xylinum seed liquid was added, and placed in a shaker with a rotation speed of 150 rpm and a temperature of 32 ° C for 72 hours to obtain bacterial cellulose / NBSK hydrogel balls. The prepared hydrogel spheres were treated with 0.1 mol / L sodium hydroxide solution in a shaker at a temperature of 80° C. and a rotation speed of 100 rpm. Rinse the hydrogel sp...

Embodiment 2

[0040] Acetobacter xylinum was inoculated in 30mL of liquid seed medium (medium composition: fructose 50g / L, peptone 5g / L, yeast extract 5g / L, sodium monohydrogen phosphate 2.6g / L, anhydrous citric acid 1.15g / L L), cultured statically for 48 hours in an incubator at 32°C. Take a 150mL Erlenmeyer flask with a sponge stopper, add 0.9g NBSK, 75mL liquid fermentation medium (the same composition as the seed medium), and adjust the pH value to 6.5 (the adjustment reagents are 0.1mol / L hydrochloric acid and 0.1mol / L Sodium hydroxide), sterilized at 121°C for 50min (198.64kPa). After the medium was cooled, 25 mL of Acetobacter xylinum seed liquid was added, and placed in a shaker with a rotation speed of 200 rpm and a temperature of 32 ° C for 72 hours to obtain bacterial cellulose / NBSK hydrogel balls. The prepared hydrogel spheres were treated with 0.1 mol / L sodium hydroxide solution in a shaker at a temperature of 80° C. and a rotation speed of 100 rpm. Rinse the hydrogel spheres...

Embodiment 3

[0042] Acetobacter xylinum was inoculated in 30mL of liquid seed medium (medium composition: fructose 50g / L, peptone 5g / L, yeast extract 5g / L, sodium monohydrogen phosphate 2.6g / L, anhydrous citric acid 1.15g / L L), cultured statically for 48 hours in an incubator at 32°C. Take a 250mL Erlenmeyer flask with a sponge stopper, add 1.25g NBSK fiber, 100mL liquid fermentation medium (the same composition as the seed medium), and adjust the pH value to 7.0 (adjusting reagents are 0.1mol / L hydrochloric acid and 0.1mol / L Sodium hydroxide), sterilized at 121°C for 50min (198.64kPa). After the culture medium was cooled, 25 mL of Acetobacter xylinum seed liquid was added, and placed in a shaker with a rotation speed of 150 rpm and a temperature of 32 ° C for 72 hours to obtain bacterial cellulose / NBSK hydrogel balls. The prepared hydrogel spheres were treated with 0.1 mol / L sodium hydroxide solution in a shaker at a temperature of 80° C. and a rotation speed of 100 rpm. Rinse the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com