A kind of nickel-cobalt double hydroxide/nico2s4 composite nanomaterial, its preparation method and its application as supercapacitor electrode material

A technology of composite nanomaterials and double hydroxides, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology, etc., can solve the problems of low capacitance and energy density, achieve good electrochemical performance, and operate Simple, easy-to-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

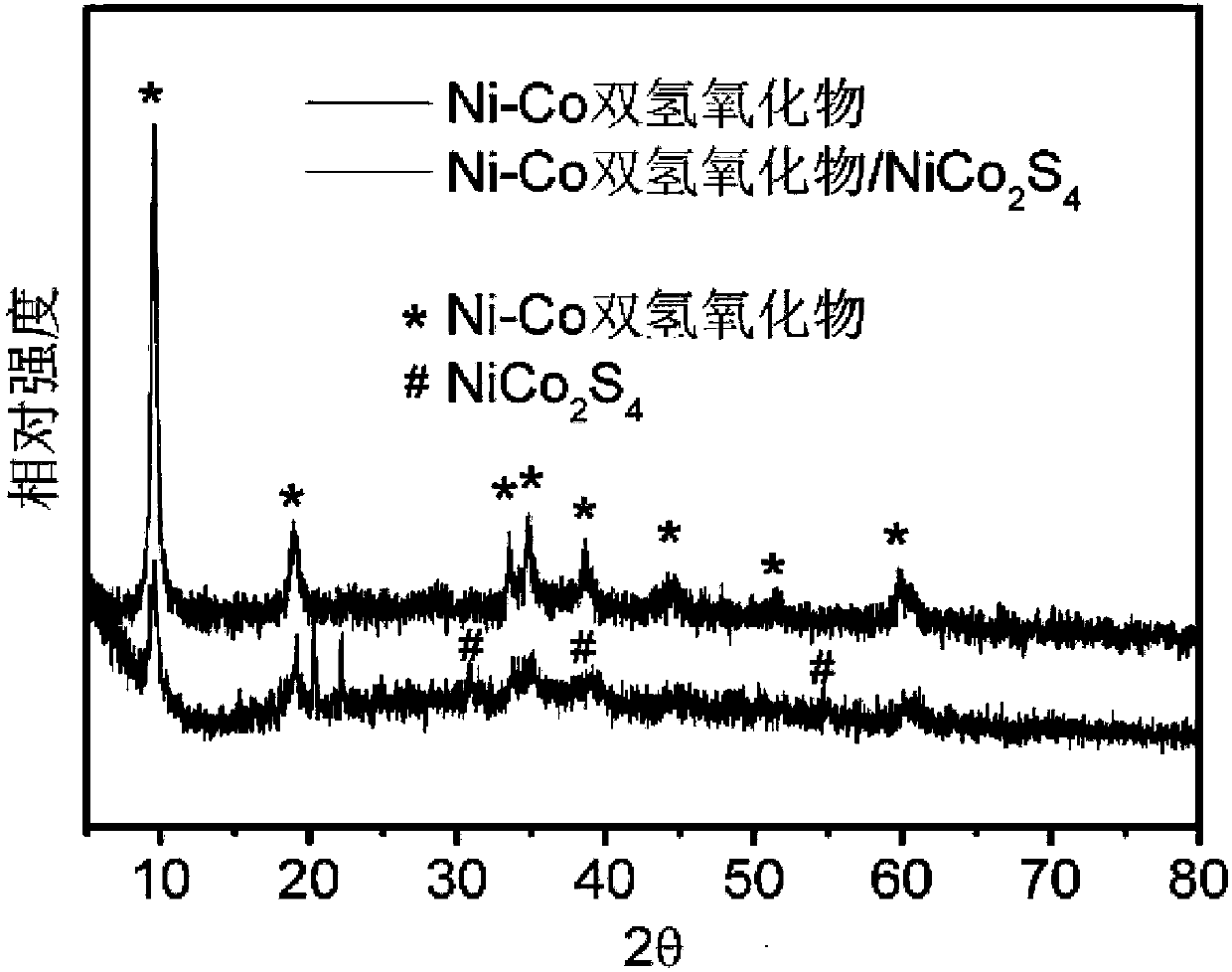

[0033] A nickel-cobalt double hydroxide / NiCo 2 S 4 A method for preparing a composite nanomaterial, comprising the steps of:

[0034] A, cobalt chloride hexahydrate, nickel chloride hexahydrate and hexamethylenetetramine are dissolved in 50mL water respectively, the concentration of cobalt salt in the solution is 0.08 mole / liter, the concentration of nickel salt is 0.04 mole / liter, six The concentration of methylenetetramine is 0.24 mol / liter. A small piece of clean nickel foam (2cm×3cm) is immersed in the mixed solution and reacted for 8 hours at 100°C. After cooling, take out the nickel foam sheet, wash it, dry it, and prepare it. A nickel foam sheet loaded with nickel-cobalt double hydroxide nanosheets was obtained;

[0035] B, put the nickel-cobalt double hydroxide nanosheet foam nickel sheet that step A made into the autoclave, add 25mL 0.17 mol / liter thioacetamide solution in the autoclave, seal the autoclave, and heat To 107°C, react for 10 hours. After the reaction...

Embodiment 2

[0039] A kind of nickel-cobalt double hydroxide / NiCo 2 S 4 The preparation method of nanocomposite material, comprises the following steps:

[0040] A. Dissolve cobalt nitrate hexahydrate, nickel nitrate hexahydrate and hexamethylenetetramine in 50mL water respectively, the concentration of cobalt salt in the solution is 0.02 mol / liter, the concentration of nickel salt is 0.01 mol / liter, hexamethylene The concentration of base tetramine is 0.06 mol / liter. A small piece of clean nickel foam (2cm×3cm) is immersed in the mixed solution and reacted at 140°C for 4 hours. After cooling, take out the foam nickel piece, wash it, and dry it to obtain a loaded Nickel foam sheets with nickel-cobalt double hydroxide nanosheets;

[0041] B. Put the nickel-cobalt double hydroxide nanosheet foam nickel sheet loaded in step A into an autoclave, add 25 mL of 0.1 mol / liter thioacetamide solution in the autoclave, seal the autoclave, and heat to 110°C, and reacted for 5 hours. After the reac...

Embodiment 3

[0043] A kind of nickel-cobalt double hydroxide / NiCo 2 S 4 The preparation method of nanocomposite material, comprises the following steps:

[0044] A. Dissolve cobalt acetate tetrahydrate, nickel acetate tetrahydrate and hexamethylenetetramine in 50mL of water respectively, the concentration of cobalt salt in the solution is 0.2 mole / liter, the concentration of nickel salt is 0.1 mole / liter, hexamethylene The concentration of base tetramine is 0.6 mol / liter. A small piece of clean foamed nickel (2cm×3cm) is immersed in the mixed solution and reacted for 10 hours at 100°C. After cooling, take out the foamed nickel piece, wash it, and dry it to obtain a load. Nickel foam sheets with nickel-cobalt double hydroxide nanosheets;

[0045] B. Put the foamed nickel sheets loaded with nickel-cobalt double hydroxide nanosheets prepared in step A into an autoclave, add 25mL of 1 mol / liter sodium sulfide solution in the autoclave, and heat the autoclave to 105 °C, react for 10 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com