Method and device for producing high-strength and high-conductivity graphene copper-based powder material

A powder material, copper-based technology, applied in the field of preparation of new functional powder materials, can solve the problems of inability to solve the dispersion and compatibility of two-phase materials, great influence on the quality of later products, unsuitable for large-scale production, etc. , to achieve the effects of excellent electrical/thermal conductivity and mechanical properties, good light transmittance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

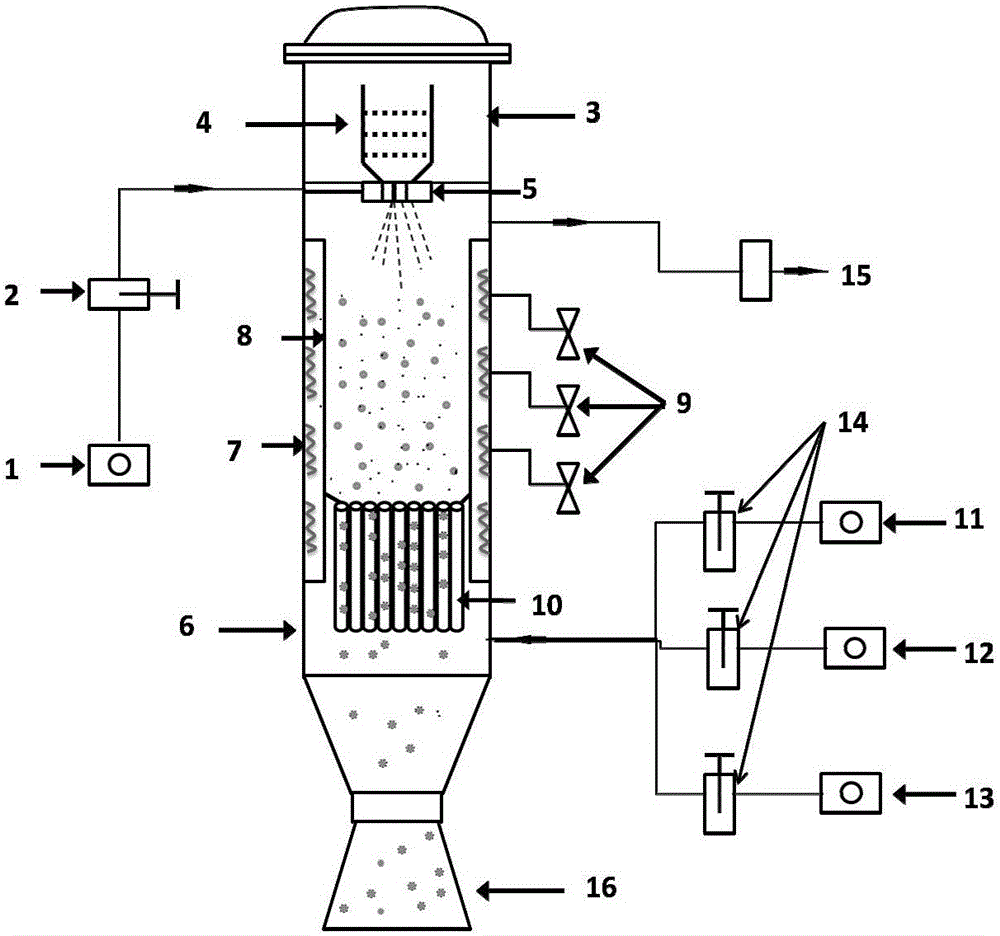

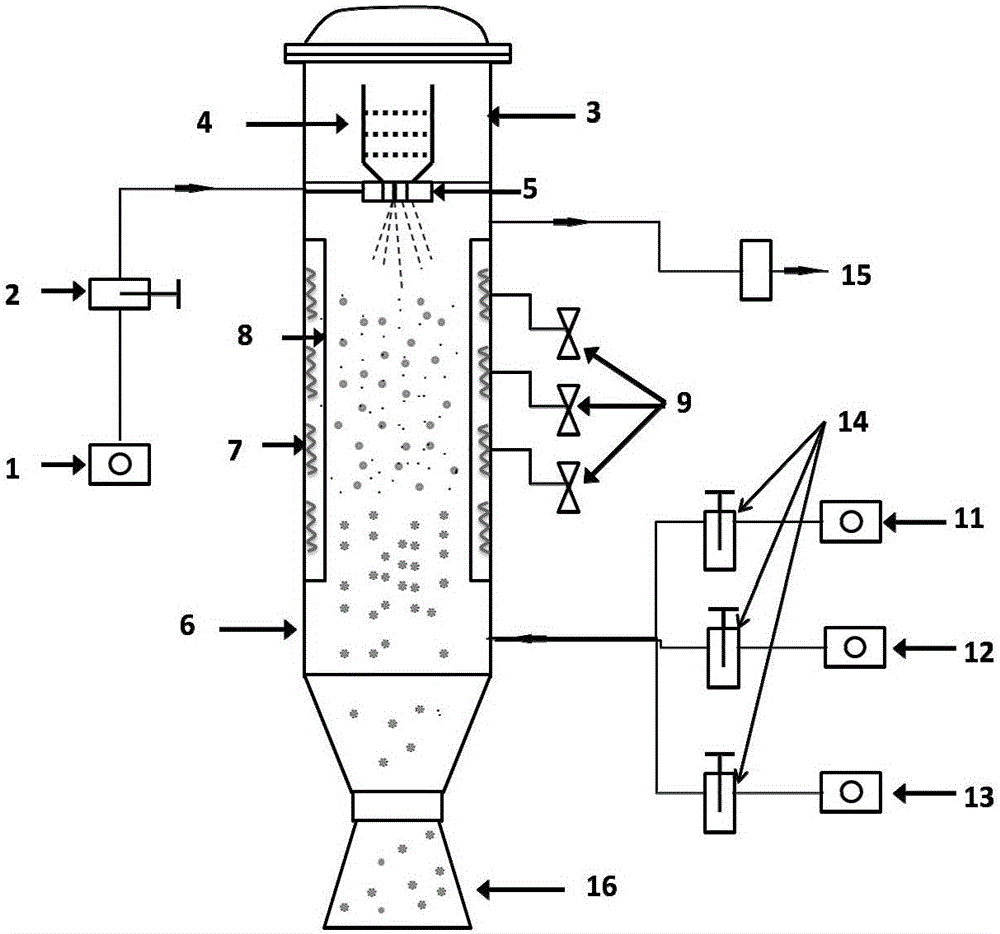

[0043] Such as figure 1 As shown, the device for producing high-strength and high-conductivity graphene copper-based powder materials provided by this embodiment includes a gas atomization powder making device, an air inlet device, a gas scrubbing device 15, a step-by-step temperature control device and a material speed reduction device 10 ;

[0044] Wherein, the gas atomization powder making device includes a high-pressure gas source system and a smelting chamber 3, an atomization chamber 6, and a collector 16 connected sequentially from top to bottom, and a crucible 4 is arranged inside the smelting chamber 3, and the crucible 4 A nozzle 5 for spraying liquid into the atomization chamber 6 is provided at the bottom, the high-pressure gas source system includes a high-pressure inert gas source 1 and a high-pressure inert gas source pressure regulating valve 2 for controlling the high-pressure inert gas source 1, and the high-pressure gas source system The inert gas source 1 ...

Embodiment 2

[0050] Such as figure 1 As shown, firstly, the air in the atomization chamber 6 and the collector 16 is drawn out through the gas scrubber 15; secondly, the argon gas source 13 and its pressure regulating valve 14 are opened to replenish the air in the atomization chamber 6 and the collector 16. Pure argon; the 3rd, repeat above-mentioned steps no less than three times, the air replacement in atomizing chamber 6 and collector 16 is clean; select methane) and its corresponding pressure regulating valve 14 to keep hydrogen entering the atomization chamber 6 with a flow of 300 sccm and methane at a flow rate of 20 sccm, and maintain the dynamic balance of the mixed gas through the scrubber 15; The 5kg copper material in 4 is heated to 1100°C for melting, and at the same time, the heating controller 9 is turned on to heat the resistance wire 6 to realize the temperature gradient of 1080°C, 950°C and 850°C from top to bottom of the heat radiation plate 8 and the atomization chamber...

Embodiment 3

[0053] The air pressure of the high-pressure inert gas source is different from the air flow and the diameter flow of the nozzle metal liquid, and the size of the gas atomized metal particles produced will also be different. Therefore, in order to obtain copper powder of different sizes, the air pressure and flow rate of the inert gas source can be adjusted. And choose different nozzle metal liquid diameter. If the basic steps described in Example 2 are adopted, the difference is that the high-pressure inert gas source 1 and the high-pressure inert gas source pressure regulating valve 2 are opened, and the gas pressure of 0.7MPa and 2m 3 The gas flow rate per minute enters the nozzle 5 with a diameter of 4mm of molten metal, sprays the molten high-temperature liquid copper into the atomization chamber 6, and obtains a graphene copper-based powder composite material with a larger particle equivalent diameter.

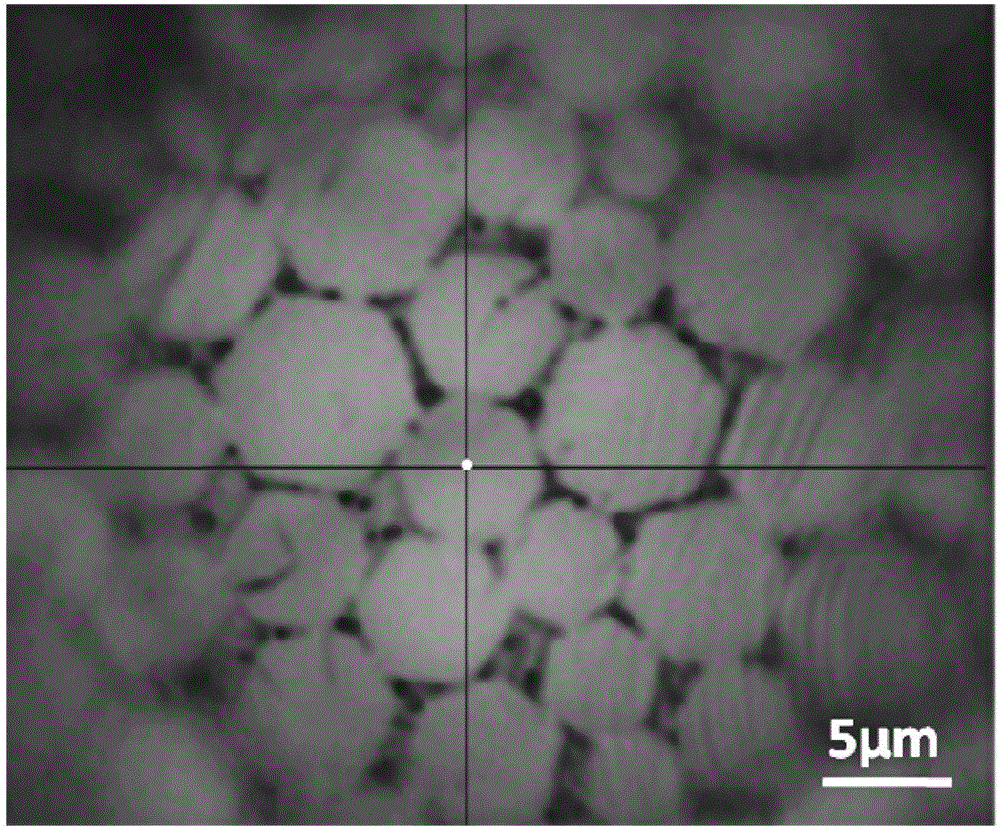

[0054] Gained graphene copper-based powder composite material Raman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com