Method for modifying wood and bamboo wood through biopolymer-chitosan

A technology of chitosan modification and biopolymer, which is applied in the direction of humidity control wood, impregnated wood, wood impregnation, etc., can solve the problems of reduced wood strength, low solubility, environmental pollution, etc., to improve dimensional stability and hardness, The effect of preventing moisture absorption and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

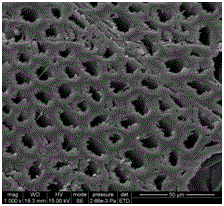

Image

Examples

Embodiment 1

[0026] Take poplar wood with a specification of 50mm×50mm×30mm (length×width×thickness) as the base material, vacuum-dry it at 102±3°C for 24 hours, then take out the poplar wood specimen for humidity control, and adjust the moisture content of the specimen to 9% in a sealed desiccator.

[0027] Take by weighing the 1-ethyl-3 methyl imidazolium chloride ionic liquid of 10g, then weigh chitosan 0.2g by 2% of its mass ratio and add in the 1-ethyl-3 methyl imidazolium chloride ionic liquid, then Stir evenly in a water bath at 90°C for 30 minutes until the chitosan mixed solution is completely dissolved into a light yellow transparent liquid, then stop heating and stirring, then take the completely dissolved chitosan solution out of the water bath and cool to room temperature After that, put it into a water bath at 40°C, and put the poplar wood specimen after the humidity adjustment treatment into the chitosan solution. Dipping, the total immersion time is 25 minutes, finally tak...

Embodiment 2

[0029] Take poplar wood with a specification of 50mm×50mm×30mm (length×width×thickness) as the base material, vacuum-dry it at 102±3°C for 24 hours, then take out the poplar wood specimen for humidity control, and adjust the moisture content of the specimen to 8% in a sealed desiccator.

[0030] Take by weighing the 1-ethyl-3 methyl imidazolium chloride ionic liquid of 10g, then weigh chitosan 0.5g by 5% of its mass ratio and add in the 1-ethyl-3 methyl imidazolium chloride ionic liquid, then Stir evenly in a water bath at 75°C for 20 minutes until the chitosan mixed solution is completely dissolved into a light yellow transparent liquid, then stop heating and stirring, then take the completely dissolved chitosan solution out of the water bath and cool to room temperature After that, put it into a water bath at 75°C, and put the poplar wood specimen after the humidity adjustment treatment into the chitosan solution. Dipping, the total immersion time is 20 minutes, finally tak...

Embodiment 3

[0032] Take poplar wood with a specification of 50mm×50mm×30mm (length×width×thickness) as the base material, vacuum-dry it at 102±3°C for 24 hours, then take out the poplar wood specimen for humidity control, and adjust the moisture content of the specimen to After 10%, put it in a sealed desiccator.

[0033]Take by weighing the 1-ethyl-3 methyl imidazolium chloride ionic liquid of 10g, then weigh chitosan 0.8 g by 8% of its mass ratio and add in the 1-ethyl-3 methyl imidazolium chloride ionic liquid, then Stir evenly in a water bath at 95°C for 35 minutes until the chitosan mixture solution is completely dissolved into a light yellow transparent liquid, then stop heating and stirring, then take the completely dissolved chitosan solution out of the water bath and cool to room temperature After that, put it into a water bath at 45°C, and put the poplar wood specimen after the humidity adjustment treatment into the chitosan solution. After soaking for 5 minutes, change the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com