Industrial wastewater treatment system for thermal power plant

A technology for industrial wastewater and treatment systems, applied in the directions of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. Complicated structure, limited treatment effect, etc., to achieve the effect of adapting to a wide range of water quality, reducing the number of auxiliary valves and piping systems, and maintaining good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

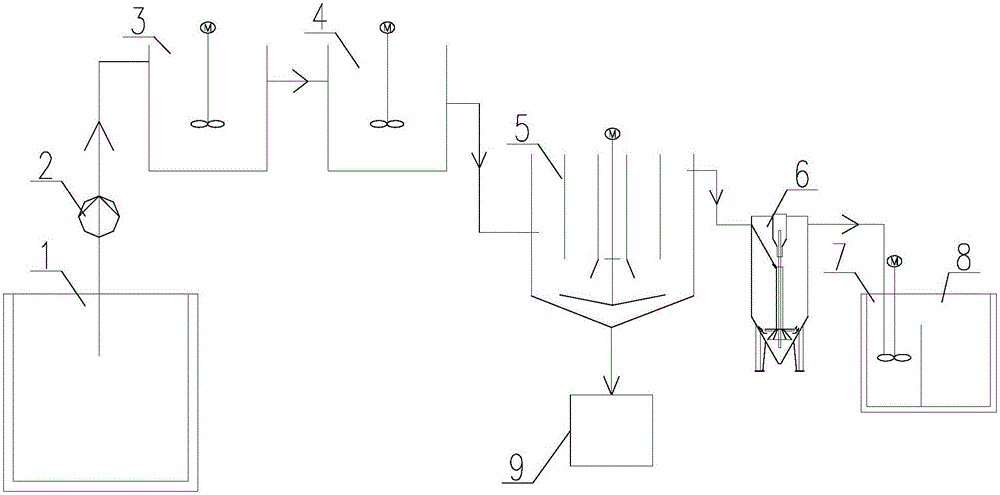

[0019] Embodiment 1 of the present invention: as figure 1 , figure 2 and image 3 Shown, a kind of thermal power plant industrial waste water treatment system is characterized in that, comprises successively connected waste water storage tank 1, waste water delivery pump 2, pH adjustment tank 3, reaction tank 4, solid contact clarifier 5, high-efficiency quicksand filter 6. The bottom of the neutralization tank 7 and the drainage tank 8, and the solid contact clarifier 5 is connected with a sludge treatment system 9.

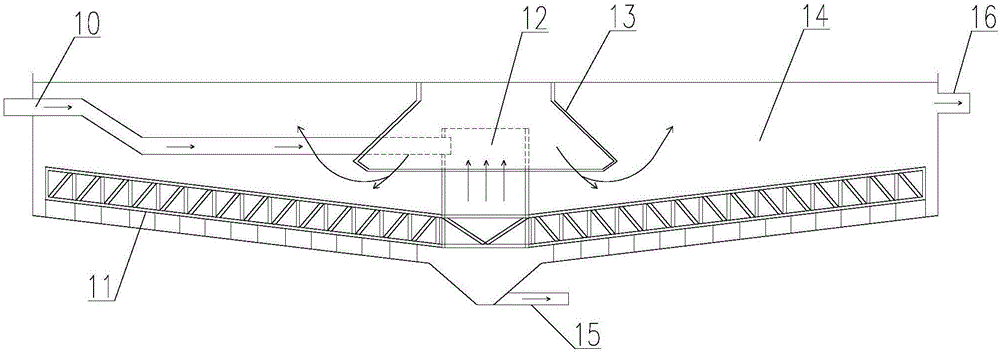

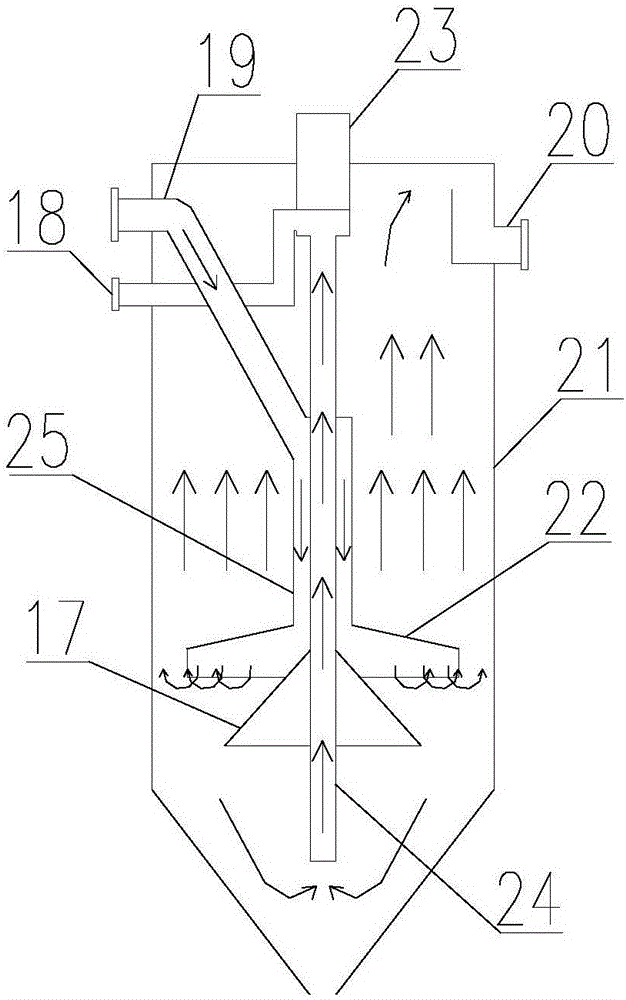

[0020] The solid contact clarifier 5 includes a tank body 14, a reaction well 13 and a diversion tube, the reaction well 13 is suspended in the tank body 14, one end of the diversion tube is located in the reaction well 13, and the other end is suspended at the bottom of the tank body 14 , the guide cylinder is provided with a lifting impeller; the water inlet pipe 10 of the solid contact clarifier 5 communicates with the guide cylinder, and the outlet pipe 1...

Embodiment 2

[0023] Embodiment 2: as figure 1 , figure 2 and image 3 As shown, an industrial wastewater treatment system for thermal power plants includes a wastewater storage tank 1 connected in sequence, a wastewater delivery pump 2, a pH adjustment tank 3, a reaction tank 4, a solid contact clarifier 5, a high-efficiency quicksand filter 6, a neutralization A sludge treatment system 9 is connected to the bottom of the pool 7, the drainage pool 8, and the solid contact clarifier 5.

[0024] The solid contact clarifier 5 includes a tank body 14, a reaction well 13 and a diversion tube, the reaction well 13 is suspended in the tank body 14, one end of the diversion tube is located in the reaction well 13, and the other end is suspended at the bottom of the tank body 14 , the guide cylinder is provided with a lifting impeller; the water inlet pipe 10 of the solid contact clarifier 5 communicates with the guide cylinder, and the outlet pipe 16 of the solid contact clarifier 5 communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com