High-performance calcium strontium zinc barium ferrite and preparation method thereof

A barium ferrite and ferrite technology, applied in the field of high-performance calcium strontium zinc barium ferrite and its preparation, can solve the problems such as the limited range of performance improvement of calcium ferrite, reduce repeated development and reduce pressure holding time, and the effect of reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] (1) First phase ferrite sintering:

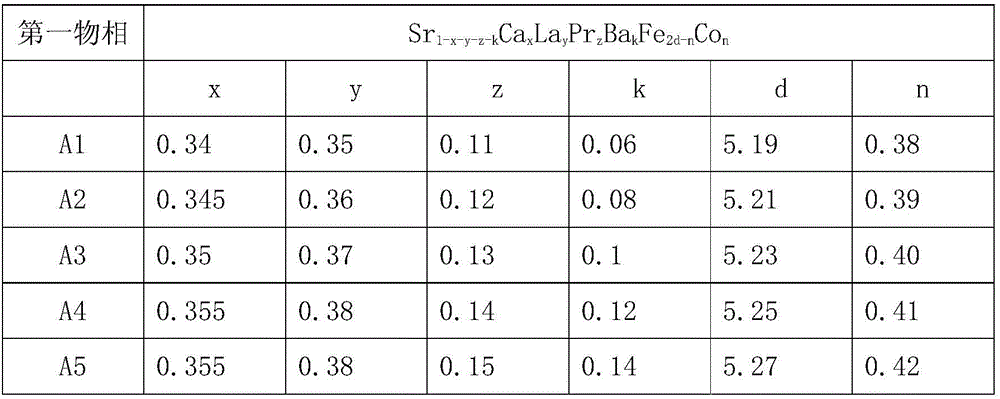

[0042] According to the molecular formula Sr 1-x-y-z-k Ca x La y PR z Ba k Fe 2d-n co n Add strontium carbonate, lanthanum hydroxide, calcium carbonate, praseodymium oxide, barium carbonate, iron oxide, and cobalt carbonate to obtain ferrite powder through mixing, drying, sintering, and crushing, and take the powder by common ball milling process for the second time Material 1Kg, add small material CaCO 3 2.0%,Si 0.9%B 2 o 3 0.3%, ball milled for 30 hours, sintered at 1300°C, tested performance after grinding. There are 5 groups of the first phase ferrite in this test, as shown in Table 1 and Table 2 for the corresponding magnetic properties.

[0043] Table 1

[0044]

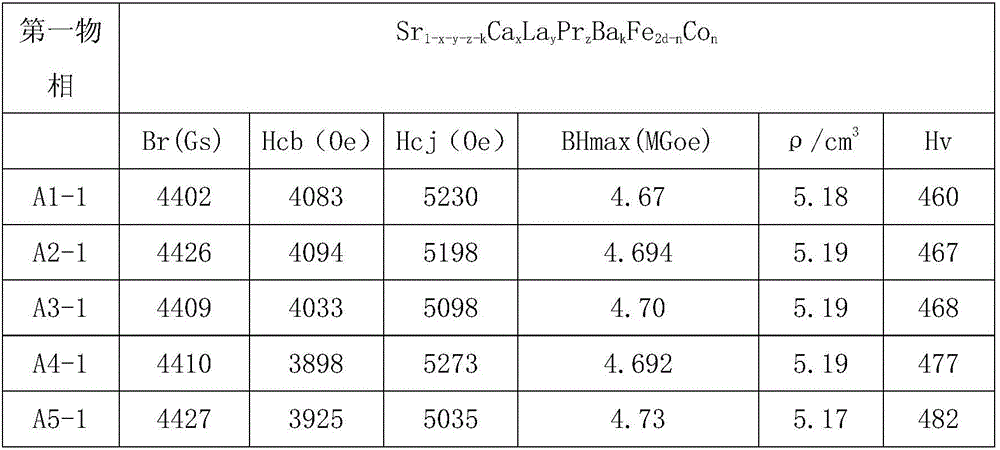

[0045] Table 2

[0046]

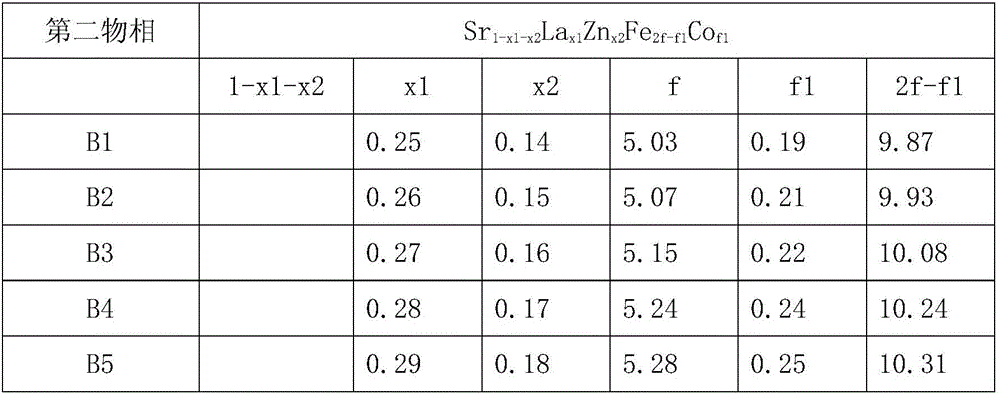

[0047] (2) Second phase ferrite sintering:

[0048] According to the molecular formula: Sr 1-x1-x2 La x1 Zn x2 Fe 2f-f1 co f1 Add strontium carbonate, lanthanum oxide, zinc oxide, iron oxide, and cobalt tetroxide to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com