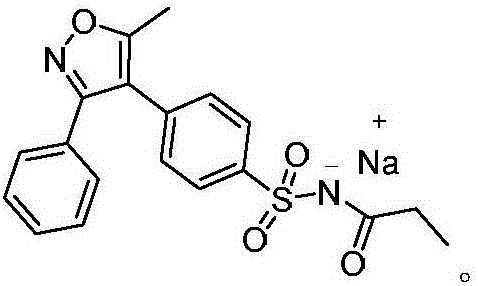

Preparation method of cyclooxygenase-2 inhibitor parecoxib intermediate

A technology of parecoxib and cyclooxygenase, which is applied in the field of drug synthesis, can solve problems such as complex reaction steps, high equipment requirements, and environmental pollution by fluoride, and achieves a high reaction yield, simple reaction steps, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

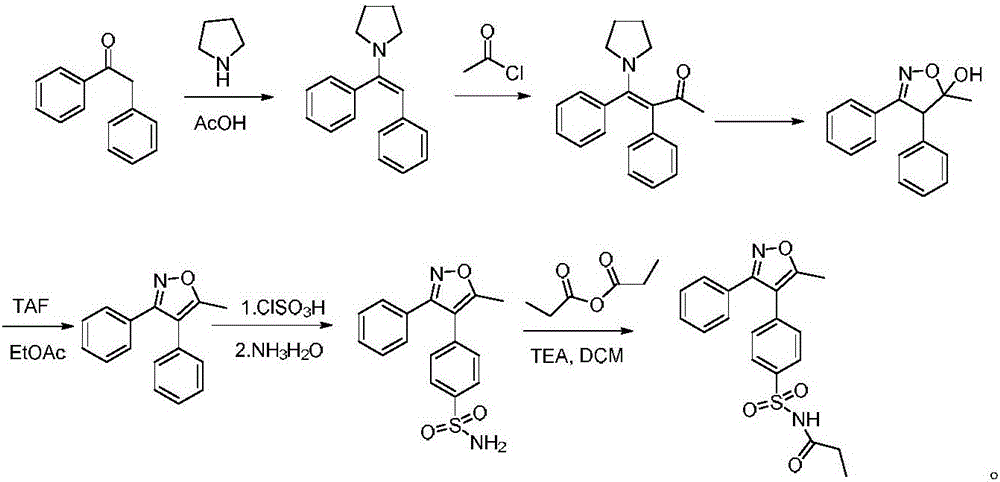

Method used

Image

Examples

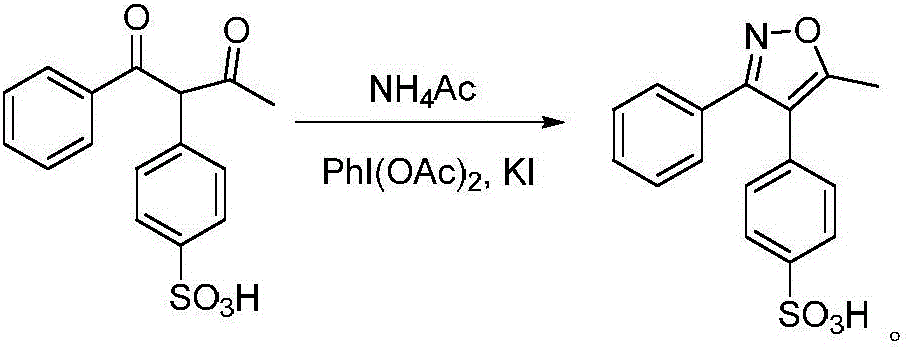

Embodiment 1

[0021] A method for preparing a parecoxib intermediate, the method comprising: 29.1 g (100 mmol) of 1-phenyl-2-(4-sulfonic acid phenyl)-2-acetyl ethyl ketone, 30.8 g of ammonium acetate (400mmol), iodobenzene diacetate 19.3g (60mmol), potassium iodide 6.6g (40mmol) join in the flask that 150ml dichloromethane is housed, 75 ℃ carry out contact reaction 1 hour, after reaction finishes, organic phase concentration, washing, Wash with saturated brine, dry over anhydrous sodium sulfate, then recrystallize from ethanol, and dry to obtain 27.5 g of the parecoxib intermediate 5-methyl-3,4-diphenylisoxazole with a yield of 87.3% and a purity of 99.60 %.

Embodiment 2

[0023] A method for preparing parecoxib intermediate, the method comprising: 29.1g (100mmol) of 1-phenyl-2-(4-sulfonic acid phenyl)-2-acetyl ethyl ketone, 38.5g of ammonium acetate (500mmol), iodobenzene diacetate 22.5g (70mmol), potassium iodide 9.9g (60mmol) join in the flask that 150ml dichloromethane is housed, 80 ℃ carry out contact reaction 1 hour, after reaction finishes, organic phase is concentrated, washed, Washed with saturated brine, dried over anhydrous sodium sulfate, recrystallized from ethanol, and dried to obtain 27.4 g of the parecoxib intermediate 5-methyl-3,4-diphenylisoxazole with a yield of 86.8% and a purity of 99.71 %.

Embodiment 3

[0025] A method for preparing parecoxib intermediate, the method comprising: 29.1g (100mmol) of 1-phenyl-2-(4-sulfonic acid phenyl)-2-acetyl ethyl ketone, 38.5g of ammonium acetate (500mmol), iodobenzene diacetate 19.3g (60mmol), potassium iodide 6.6g (40mmol) join in the flask that 150ml dichloromethane is housed, 85 ℃ carry out contact reaction 0.5 hour, after reaction finishes, organic phase is concentrated, washed, Washed with saturated brine, dried over anhydrous sodium sulfate, then recrystallized from ethanol, and dried to obtain 26.5 g of the parecoxib intermediate 5-methyl-3,4-diphenylisoxazole with a yield of 84.5% and a purity of 99.33 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com