Medical high-strength ti-6al-4v alloy wire and its preparation process and application

A ti-6al-4v, alloy wire technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of surface scratches, lubricant requirements, etc., to improve strength, reduce machining allowance, and dimensional accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

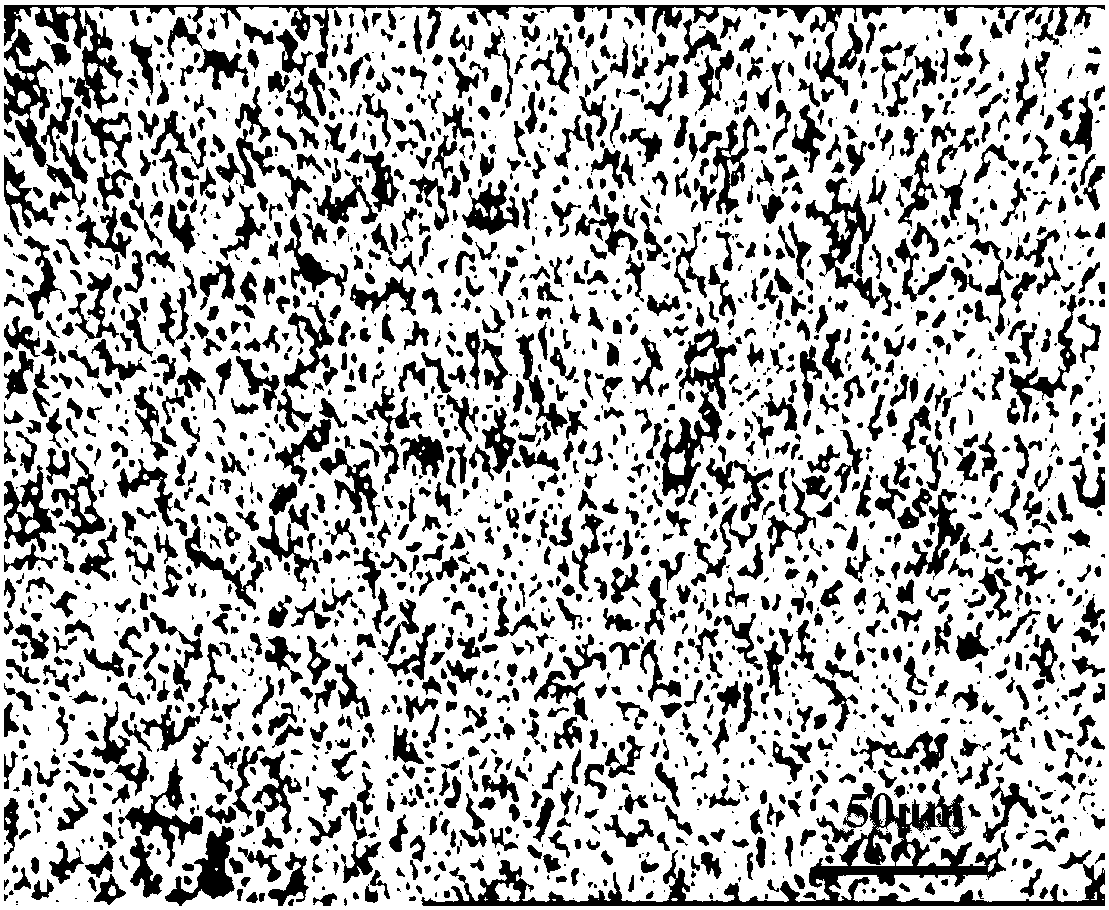

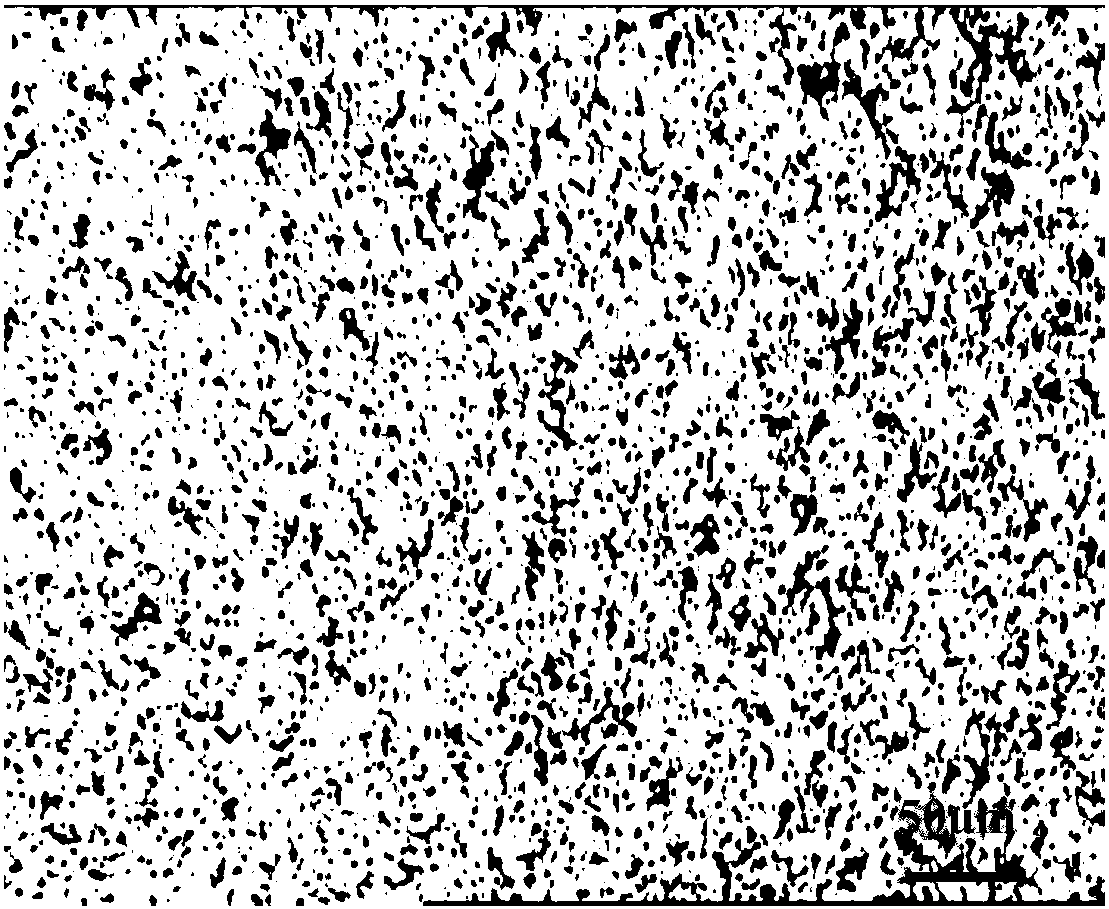

Image

Examples

Embodiment 1

[0045] The production process of the medical Ti-6Al-4V alloy wire with a diameter of 2.0mm for manufacturing children's intramedullary nails, its implementation steps are as follows:

[0046] (1) Melting

[0047] The raw material is grade 1 sponge titanium, and the sponge titanium, aluminum vanadium alloy, aluminum beans, iron powder, and titanium dioxide are mixed according to a certain proportion, and then pressed with a press to form an electrode. Put it into a vacuum consumable arc melting furnace and melt it 3 times to make alloy ingot.

[0048] (2) forging

[0049] The ingot is heated to 1050℃~1150℃ by an electric furnace, and the blank is forged Final forging temperature ≥ 830°C.

[0050] (3) Double rolling with large deformation

[0051] Use an electric furnace to heat to 900°C-950°C (±5°C), hold time for 60-90min, and finish rolling temperature ≥ 800°C.

[0052] (4) cold drawn

[0053] Will After the blanks are subjected to temperature-controlled hot-draw...

Embodiment 2

[0073] The production process of the medical Ti-6Al-4V alloy wire with a diameter of 3.5mm for manufacturing children's intramedullary nails, its implementation steps are as follows:

[0074] (1) Melting

[0075] The raw material is grade 1 sponge titanium, and the sponge titanium, aluminum vanadium alloy, aluminum beans, iron powder, and titanium dioxide are mixed according to a certain proportion, and then pressed with a press to form an electrode. Put it into a vacuum consumable arc melting furnace and melt it 3 times to make alloy ingot.

[0076] (2) forging

[0077] The ingot is heated to 1050℃~1150℃ by an electric furnace, and the blank is forged Final forging temperature ≥ 830°C.

[0078] (3) Double rolling with large deformation

[0079] Use an electric furnace to heat to 900°C-950°C (±5°C), hold time for 60-90min, and finish rolling temperature ≥ 800°C.

[0080] (4) cold drawn

[0081] Will After the blanks are subjected to temperature-controlled hot-draw...

Embodiment 3

[0101]The production process of the medical Ti-6Al-4V alloy wire with a diameter of 4.0mm for manufacturing children's intramedullary nails, its implementation steps are as follows:

[0102] (1) Melting

[0103] The raw material is grade 1 sponge titanium, and the sponge titanium, aluminum vanadium alloy, aluminum beans, iron powder, and titanium dioxide are mixed according to a certain proportion, and then pressed with a press to form an electrode. Put it into a vacuum consumable arc melting furnace and melt it 3 times to make alloy ingot.

[0104] (2) forging

[0105] The ingot is heated to 1050℃~1150℃ by an electric furnace, and the blank is forged Final forging temperature ≥ 830°C.

[0106] (3) Double rolling with large deformation

[0107] Use an electric furnace to heat to 900°C-950°C (±5°C), hold time for 60-90min, and finish rolling temperature ≥ 800°C.

[0108] (4) cold drawn

[0109] Will After the blanks are subjected to temperature-controlled hot-drawi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com