Method for preparing polyimide-silicon dioxide composite nanofiber membrane with crosslinking morphology

A technology of composite nanofibers and silica, applied in fiber processing, filament/thread forming, textile and papermaking, etc. Interaction and other issues, to achieve the effects of process-based and industrialized preparation, improved mechanical strength and dimensional stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

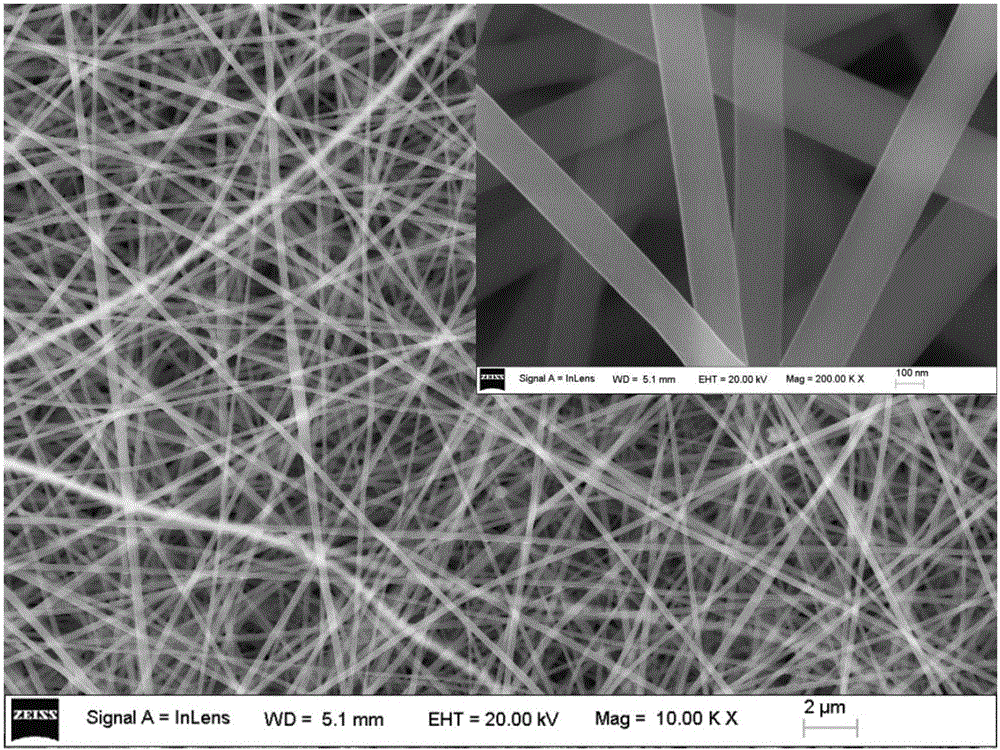

Embodiment 1

[0040] Use pyromellitic dianhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) as dibasic anhydride and diamine monomer respectively, and N,N-dimethylformamide (DMF) as solvent , polycondensation to obtain a polyamic acid solution, the solid content is 12%, the quality of the silicon dioxide precursor added is 40% of the quality of the polyimide generated after imidization, and the quality of the silicon dioxide finally generated after all the reactions , the polyamic acid / silicon dioxide precursor nanofiber membrane was prepared by electrospinning method, and the subsequent treatment process was (a) direct high-temperature thermal imidization without hydrolysis treatment, and the temperature was raised from room temperature to 300 ° C at a uniform speed for 120 minutes , and keep it warm for 120min; (b) heat imidization at high temperature first, heat up from room temperature to 300°C at a constant speed for 120min, keep it warm for 120min, hang it in a sealed 650mL container...

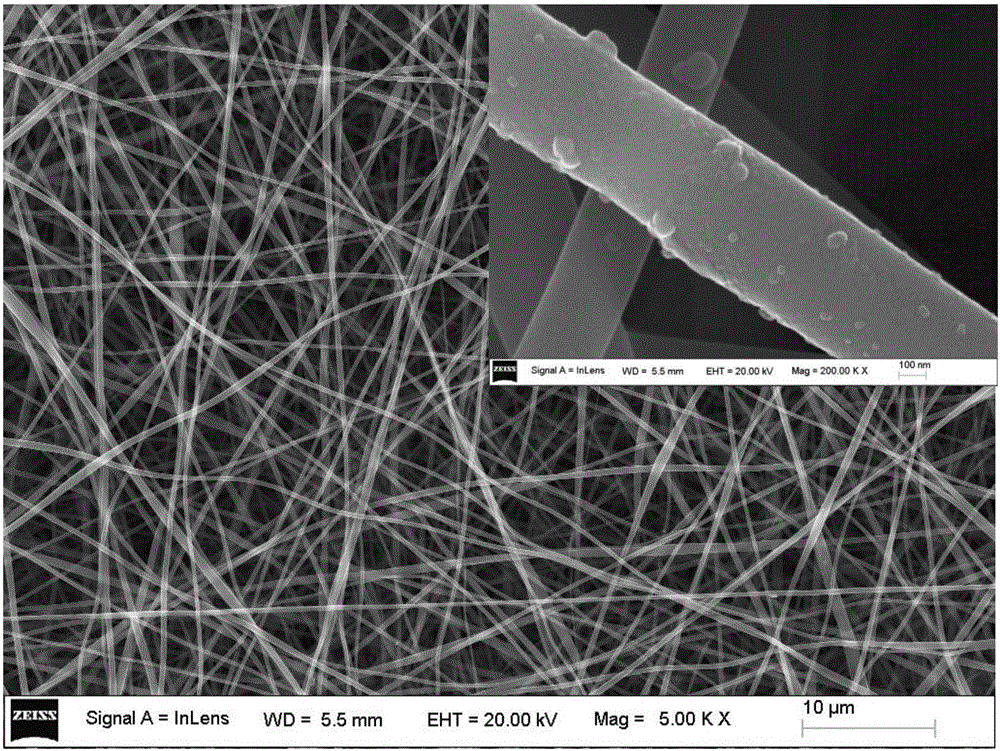

Embodiment 2

[0042] Using PMDA and ODA as dibasic anhydride and diamine monomers respectively, and DMF as solvent, polyamic acid solution is polycondensed, with a solid content of 12%. The quality of silicon oxide accounts for 40% of the mass of polyimide after imidization, and the polyamic acid / silicon dioxide precursor nanofiber film is prepared by electrospinning, and the subsequent treatment processes are (a) at 120 ° C Insulate for 60 minutes, hang it in a sealed 650mL container with 40mL of mixed hydrolyzate after cooling, take it out after insulated at 65°C for 12h, heat imidize, heat up from room temperature to 300°C at a constant speed for 120min, and keep warm for 60min; ( b) Insulate at 120°C for 60 minutes, hang it in a sealed 650mL container with 40mL of mixed hydrolyzate after cooling, take it out after heat preservation at 65°C for 36h, heat imidization, and heat up from room temperature to 300°C at a constant speed over 120 minutes , and keep warm for 60min. The morphology...

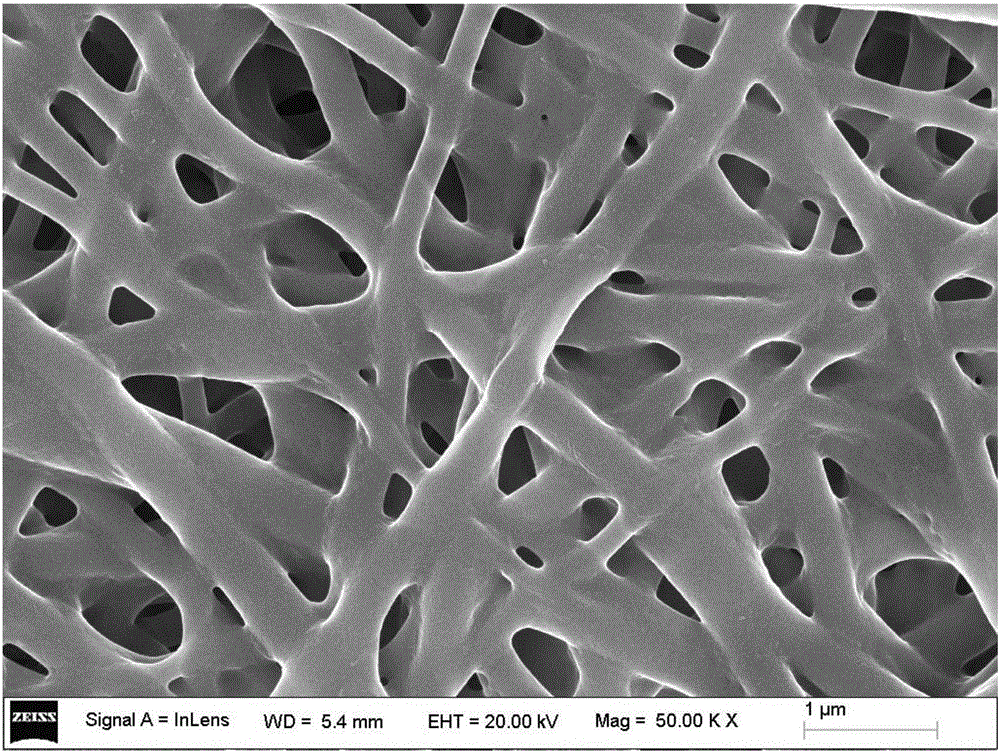

Embodiment 3

[0044] Using PMDA and ODA as dibasic anhydride and diamine monomers respectively, and DMF as solvent, polyamic acid solution is polycondensed, with a solid content of 12%. The mass of silicon oxide accounts for 40% of the mass of polyimide produced after imidization, and the polyamic acid / silicon dioxide precursor nanofiber film is prepared by electrospinning, and the subsequent treatment processes are (a) at 120 °C Insulate for 60 minutes at low temperature, hang it in a sealed 650mL container with 35mL of mixed hydrolyzate after cooling, take it out after 24 hours of heat preservation at 65°C, heat imidization, and heat up from room temperature to 300°C at a uniform speed for 120 minutes, and hold for 60 minutes; (b) Insulate at 120°C for 60 minutes, hang it in a sealed 650mL container with 40mL of mixed hydrolyzate after cooling, take it out after heat preservation at 65°C for 24h, heat imidization, and heat up from room temperature to 300°C at a constant speed for 120 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com