K hole doped polycrystalline SnSe and preparation method therefor

A hole and vacuum technology, which is applied in the manufacture/processing of thermoelectric devices, as well as in the direction of thermoelectric device junction lead wire materials, etc., to achieve the effect of strong practicability, improved electrical performance, and increased carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

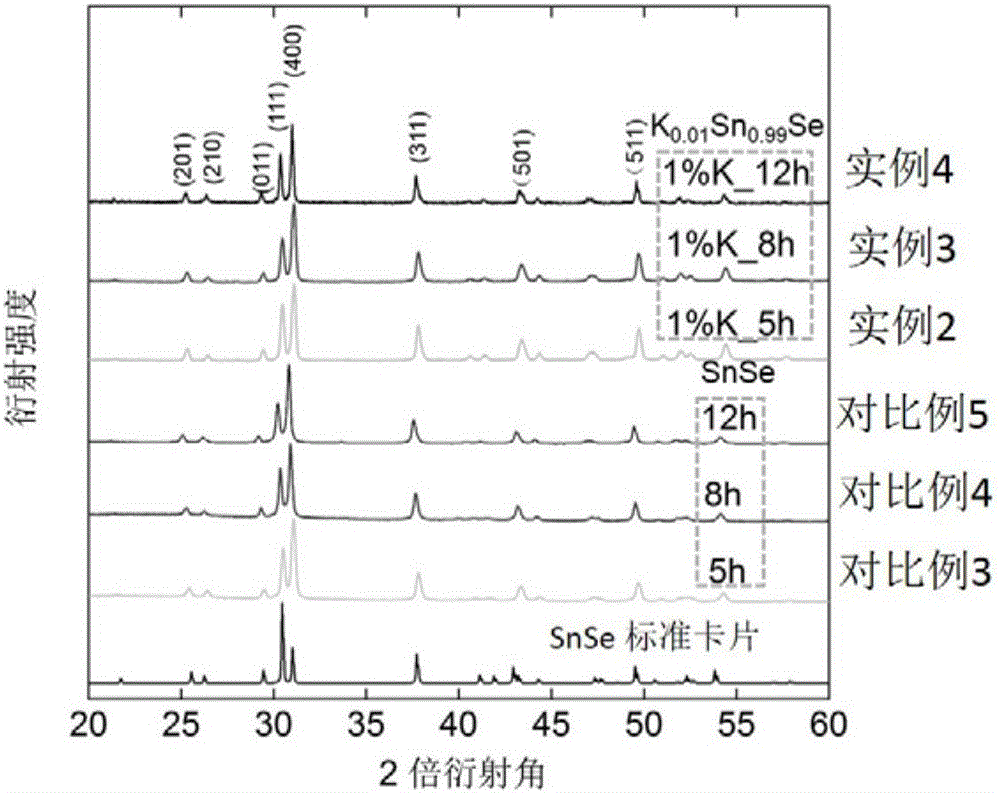

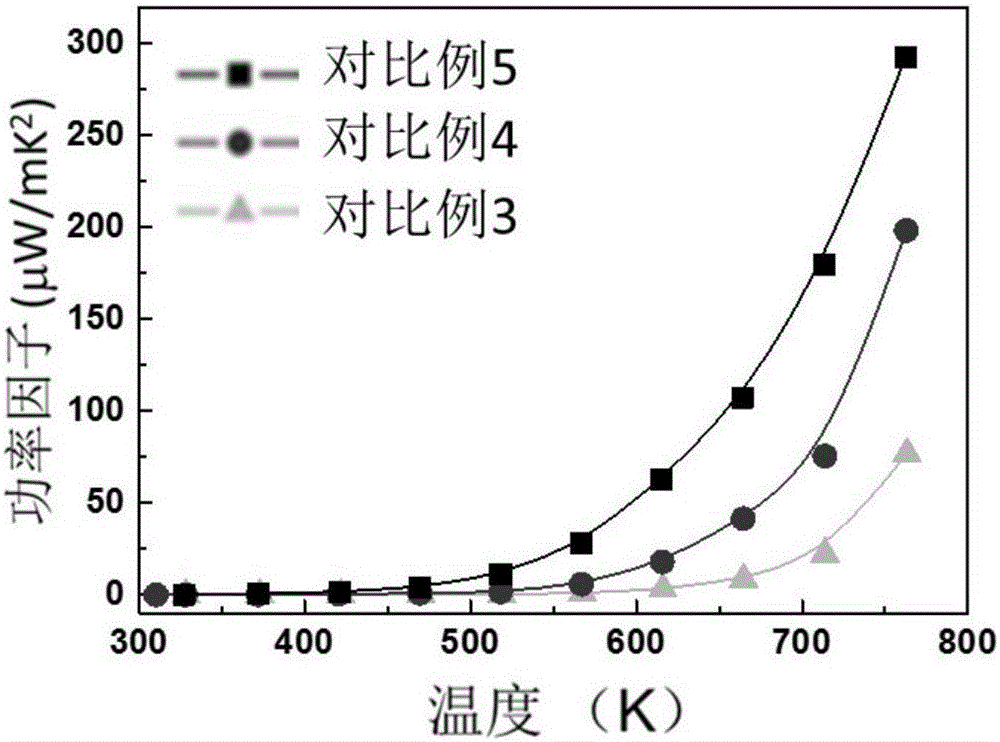

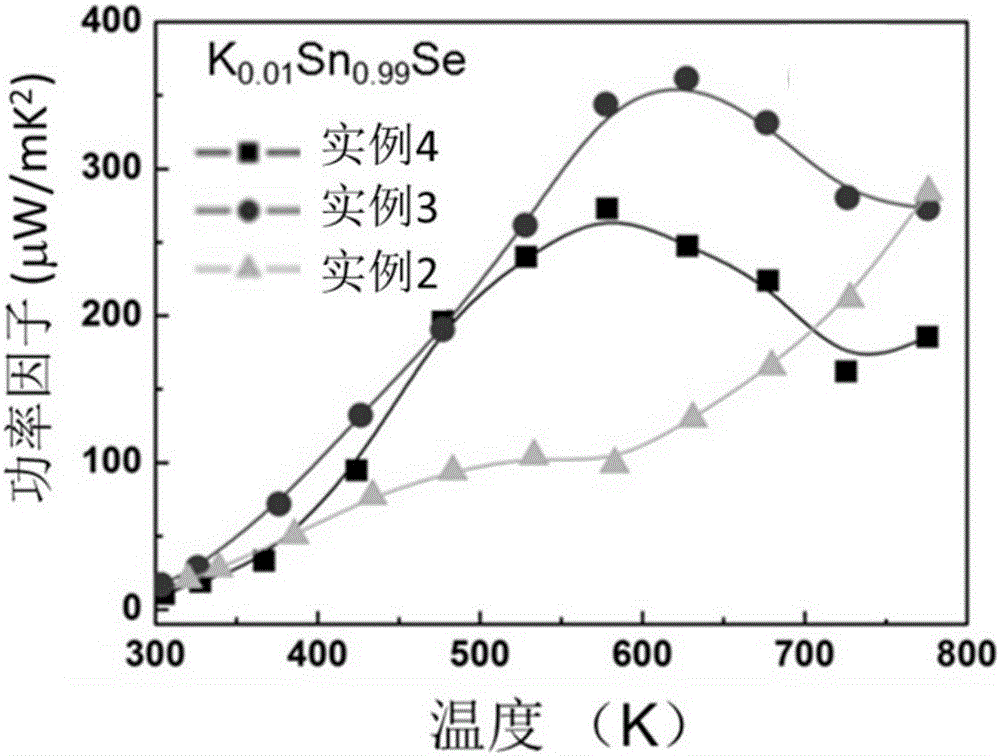

[0047] First, use an improved mechanical alloying method to prepare SnSe-based precursor fine powders. This method is to use high-purity Sn, K and Se elemental powders (purity greater than 99.999%) according to the molar percentage of Sn elemental Se elemental substance is 90% ~ 100% and does not contain 100%, the molar percentage of K elemental substance in Se elemental substance is 0% to 10% and does not contain 0%, and it is ensured that the total mass of Sn elemental substance and K elemental substance is equal to the molar fraction of Se elemental substance, in the presence of N 2 Weigh it in the glove box under the atmosphere and put it into a ball mill jar, put it into a planetary high-energy ball mill, and feed it with N 2 Mixed gas with Ar, sealed, mechanically alloyed, and dry ball milled to obtain K-doped SnSe-based fine powder, and then sintered K-doped SnSe-based powder by spark plasma sintering (SPS) to prepare a block Material K is hole-doped polycrystalline SnS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com