A method for treating corn stalks with steam explosion system n-methyl-n-oxide morpholine

A technology of corn stalks and oxidized morpholine, which is applied in the field of chemical engineering, can solve problems such as hydrochloric acid environmental pollution, and achieve the effects of avoiding acid and alkali corrosion, efficient pretreatment and saccharification, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

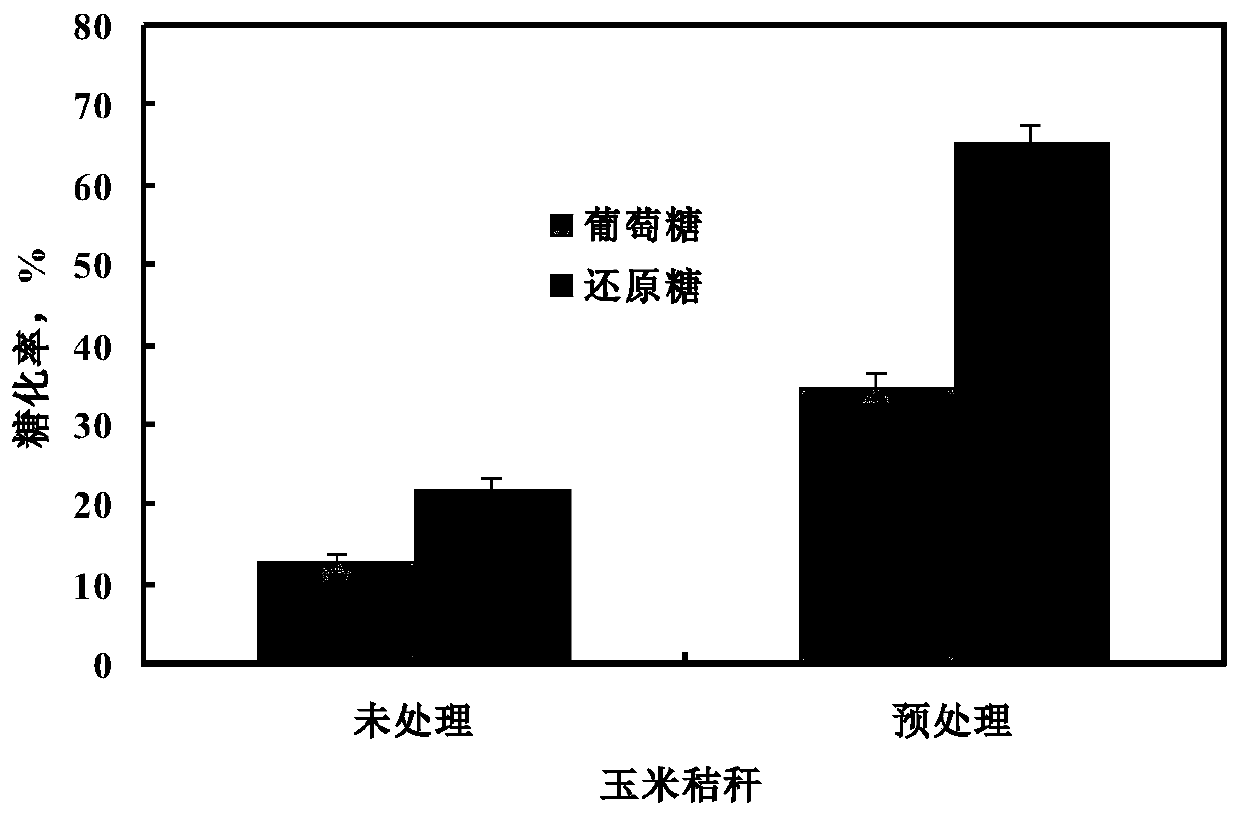

[0027] In the pretreatment system, 0.2g of dry corn stalks was mixed with 85% (w / w) NMMO and 15% (w / w) (mass ratio of straw, NMMO, water: 2:85:15) at 110 After pretreatment for 2 hours under the conditions of ℃ and 0.078MPa, water was added to obtain a regenerated cellulose material. After the regenerated cellulose material was washed with water for 3 times, pH=4.8 acetic acid-sodium acetate buffer solution (50mmol / L) was added to form a mixed system, the final mass concentration of corn stalks was 20g / L, and cellulase was added (the dosage of cellulase was 30FPU / g substrate) to carry out enzymolysis, shake reaction 72h on the constant temperature shaker of 50 ℃ and 180rpm, the yield of reducing sugar is 65.3%, and the yield of glucose is 34.8% ( figure 1 ).

Embodiment 2

[0029] In the pretreatment system, 0.2g of dry corn stalks was mixed with 85% (w / w) NMMO-15% (w / w) water (mass ratio of straw, NMMO, water: 2:85:15) at 120 After the corn stover was pretreated for 0.75 h under the conditions of ℃ and 0.13 MPa, water was added to obtain the regenerated cellulose material. After the regenerated cellulose material was washed with water for 4 times, pH=4.8 acetic acid-sodium acetate buffer solution (50mmol / L) was added to form a mixed system, the final mass concentration of corn stalks was 20g / L, and cellulase was added (the dosage of cellulase was 30 FPU / g substrate) for enzymolysis, shaking reaction on a constant temperature shaker at 50°C and 180rpm for 72h, the yield of reducing sugar was 65.1%, and the yield of glucose was 34.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com