Manufacturing method of BiCMOS integrated circuit

A manufacturing method and integrated circuit technology, which is applied in the field of device manufacturing, can solve the problems of small reverse withstand voltage of devices, and achieve the effect of improving reverse withstand voltage and increasing the maximum working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

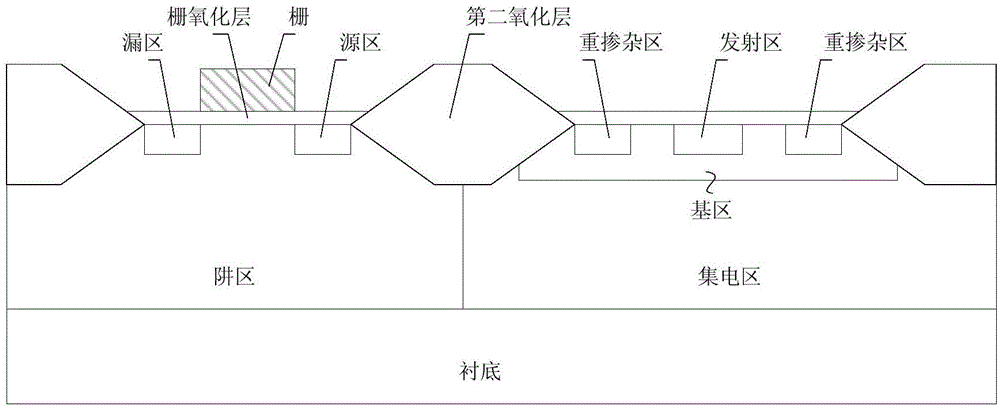

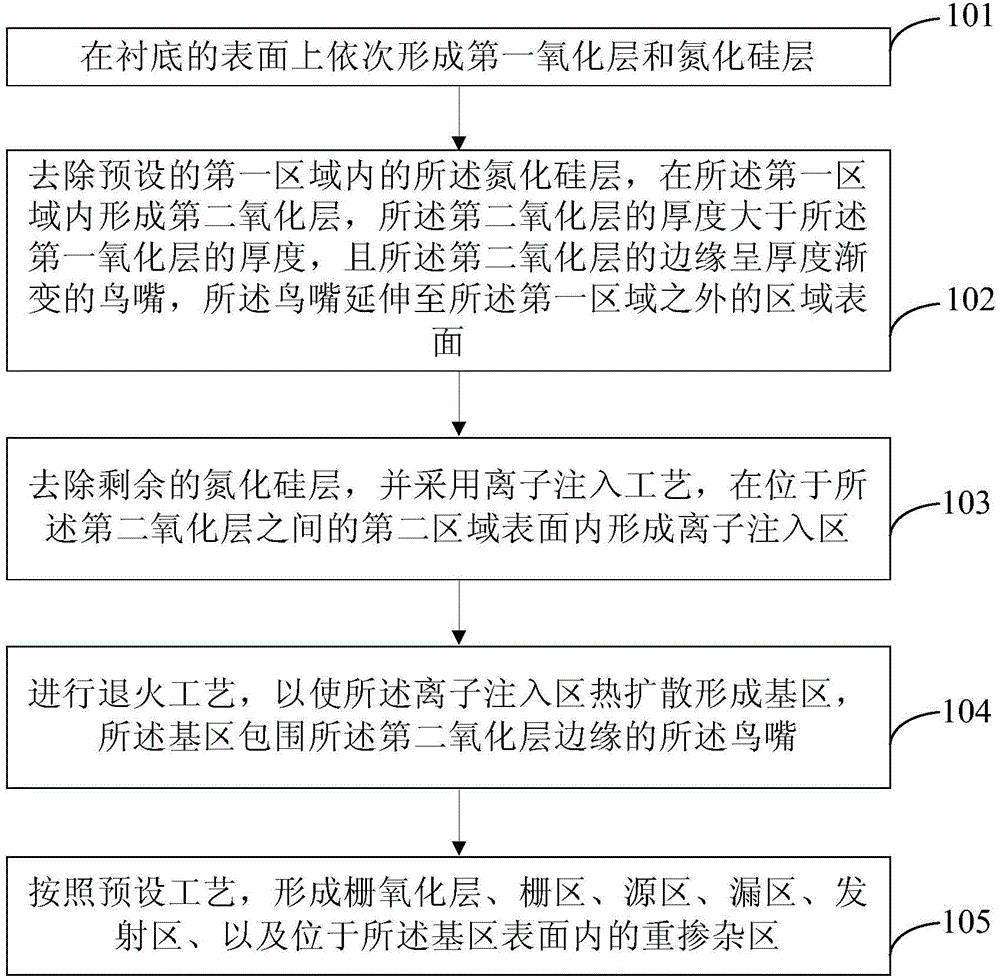

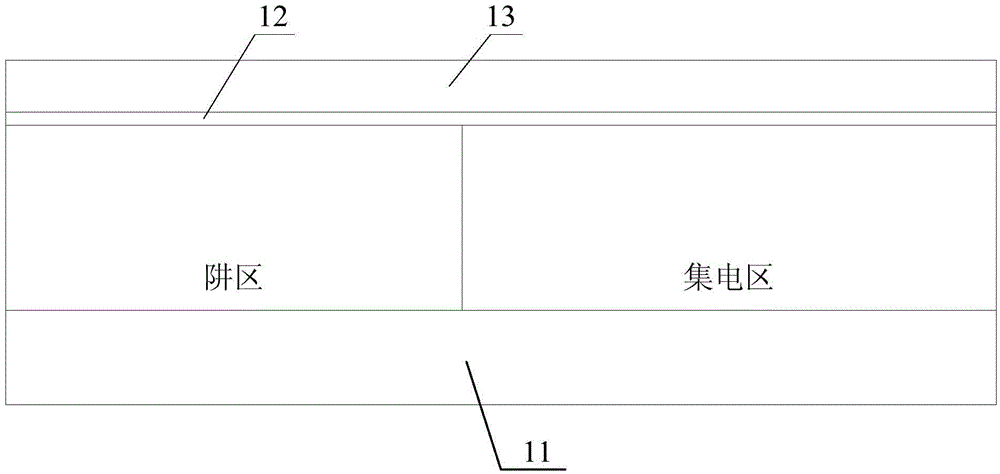

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. For convenience of description, the sizes of different layers and regions are enlarged or reduced, so the sizes and ratios shown in the drawings do not necessarily represent actual sizes, nor do they reflect the proportional relationship of sizes.

[0023] The semiconductor manufacturing process is a series of process steps implemented on the semiconductor wafer, including photolithography, ion implantation, annealing, oxidation, growing thin film layers, dry etching, wet etching, etc. The semiconductor wafer is a wafer-shaped semiconductor The substrate of the material. Semiconductors include single crystal silicon and polycrystalline silicon. Doping impurity e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com