Method for processing Bayer process red mud through calcification-carbonization one-step method

A technology of Bayer red mud and step method, which is applied in the production of alumina/hydroxide, cement, etc., can solve the problem of not completely solving the problem of energy consumption in the production process of red mud containing alkali, and achieve the reduction of mine consumption and energy consumption. Consumption and operating costs, the effect of low production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

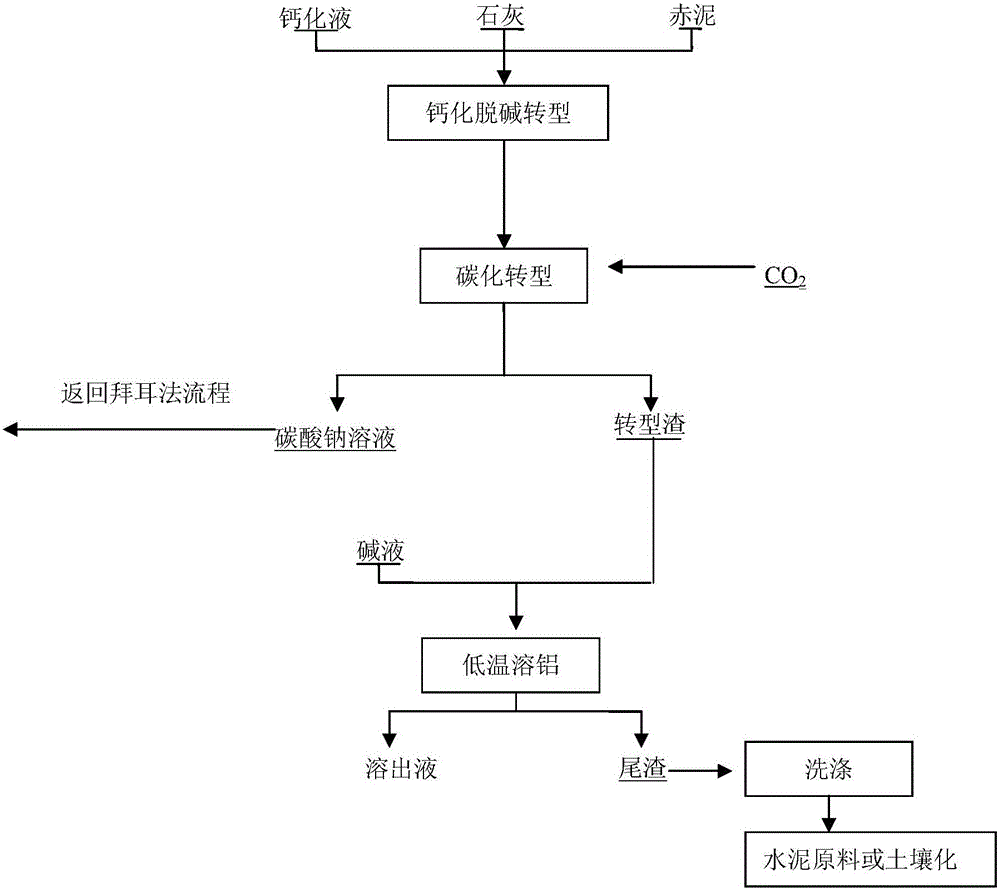

[0042] The method for processing Bayer process red mud by calcification-carbonization one-step method specifically comprises the following steps:

[0043] Step 1, Calcification Transformation

[0044] (1) Mix Bayer process red mud, lime and clear water to form a mixed slurry with a ratio of liquid volume to solid mass of 2:1; wherein, according to m 1 :m 2 = 0.5;

[0045] (2) Carry out calcification transformation under the condition that the temperature of the mixed pulp is 80°C and the reaction time is 20 minutes;

[0046] In step 1, the main reaction of the calcification transformation process is (1);

[0047] Step 2, carbonization transformation

[0048] (1) In the slurry system formed after calcification transformation, add clear water to adjust the ratio of liquid volume to solid mass in the slurry system to 3:1;

[0049] (2) Into the adjusted pulp system, feed CO 2 Component gas, CO 2 The gas partial pressure is 0.4MPa, and the carbonization transformation is car...

Embodiment 2

[0055] The method for processing Bayer process red mud by calcification-carbonization one-step method specifically comprises the following steps:

[0056] Step 1, Calcification Transformation

[0057] (1) Mix Bayer process red mud, lime and water to form a mixed slurry with a ratio of liquid volume to solid mass of 3:1; wherein, according to m 1 :m 2 = 1;

[0058] (2) Carry out calcification transformation under the condition that the mixed ore pulp is at a temperature of 90°C and a reaction time of 40 minutes;

[0059] In step 1, the main reaction of the calcification transformation process is (1);

[0060] Step 2, carbonization transformation

[0061] (1) In the slurry system formed after calcification transformation, add clear water to adjust the ratio of liquid volume to solid mass in the slurry system to 4:1;

[0062] (2) Into the adjusted pulp system, feed CO 2 Component gas, CO 2 The gas partial pressure is 0.6MPa, and the carbonization transformation is carried ...

Embodiment 3

[0068] The method for processing Bayer process red mud by calcification-carbonization one-step method specifically comprises the following steps:

[0069] Step 1, Calcification Transformation

[0070] (1) The Bayer process red mud, lime and Na 2 Sodium hydroxide solution with O mass concentration ≤ 40g / L is mixed to form a mixed slurry with a ratio of liquid volume to solid mass of 4:1; wherein, according to m 1 :m 2 = 2;

[0071] (2) Carry out calcification transformation under the condition that the temperature of the mixed pulp is 100°C and the reaction time is 60 minutes;

[0072] In step 1, the main reaction of the calcification transformation process is (1);

[0073] Step 2, carbonization transformation

[0074] (1) Add Na to the slurry system formed after calcification transformation 2 O sodium hydroxide solution with mass concentration ≤ 40g / L, adjust the ratio of liquid volume to solid mass in the slurry system to 5:1;

[0075] (2) Into the adjusted pulp system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com