Extraction method of purple corn anthocyanin

An extraction method, the technology of purple corn, applied in the direction of organic chemistry, can solve the problems of high toxic and side effects of organic solvents, low extraction efficiency, time-consuming operation, etc., and achieve high product quality, fast extraction speed, and less waste liquid discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

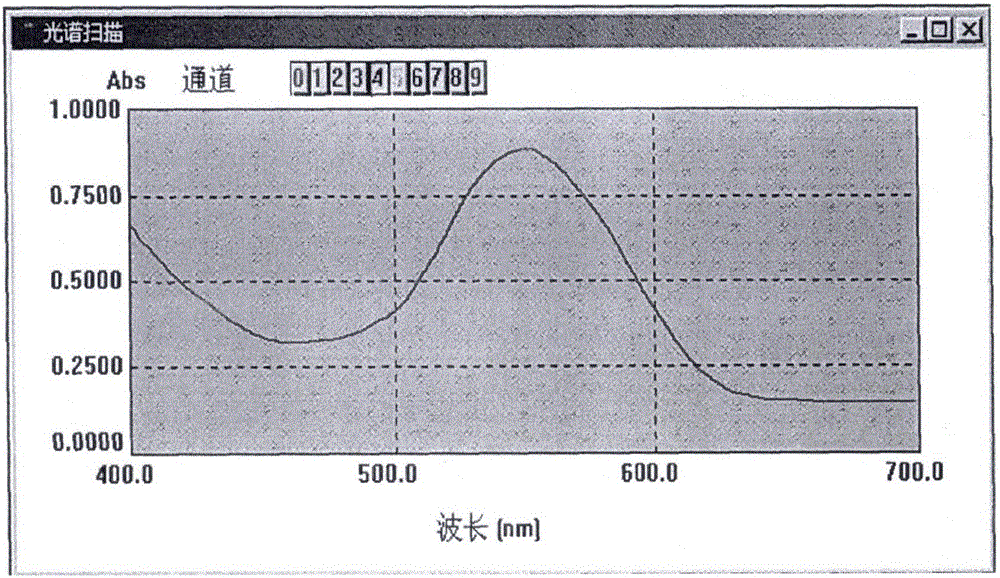

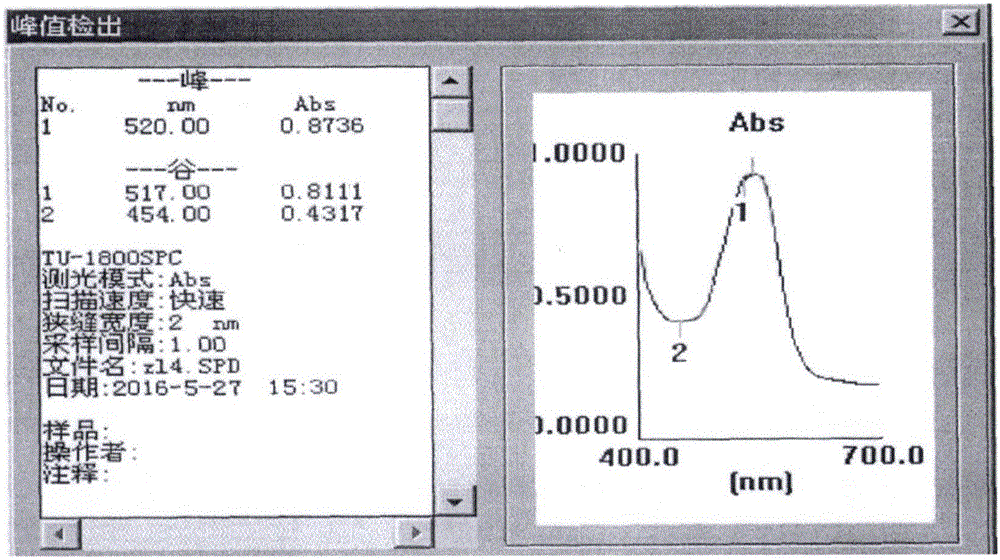

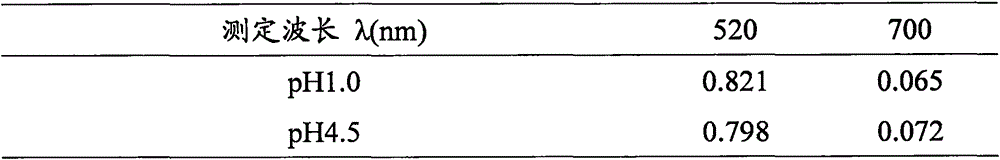

[0056] Extraction of Anthocyanins from Jinheiyu No. 2 Corn Kernels

[0057] The grains of Jin Heiyu No. 2 were used as raw materials, dried at 35°C at low temperature, and then crushed into 40-mesh fine powder. 10.0 g of the crushed Jin Heiyu No. 2 corn fine powder was accurately weighed, placed in a conical flask, and The mixed solution of 95% ethanol, 0.1mol / L citric acid and distilled water with a volume ratio of 4:1:3 is used as the extraction solution, and 100ml of the extraction solution is added to the conical flask. Extract anthocyanins from Jinheiyu No. 2 corn fine powder for 30 minutes under the assistance of ultrasonic waves with a power of 400W; centrifuge the mixture after ultrasonic-assisted extraction at a speed of 8000 rpm / min for 10 minutes, and then separate the filter residue and filtrate , carry out secondary extraction, the extraction time is halved, centrifuged at a speed of 8000rpm / min again, and the two filtrates are mixed; the filtrate is vacuum concen...

Embodiment 2

[0066] Extraction of Anthocyanins from Zhuozi No.1 Corn Kernel

[0067] Use Zhuozi No. 1 corn grains as raw materials, dry them at 35°C at low temperature, and then crush them into 60-mesh fine powder. Accurately weigh 10 g of the crushed Zhuozi No. 1 corn fine powder, place them in a conical flask, and measure Be the mixed solution of 90% ethanol, 0.2mol / L citric acid and distilled water of 4: 2: 5 as extracting solution, add the extracting solution of 100ml in the Erlenmeyer flask, after mixing evenly, at extraction temperature 45 ℃, ultrasonic power is Under the assisted action of 450W ultrasonic waves, anthocyanins were extracted from Zhuozi No. 1 corn fine powder for 35 minutes; The second extraction, the extraction time was halved, centrifuged again at a speed of 8000rpm / min, and the two filtrates were mixed; the filtrate was vacuum concentrated in a rotary evaporator, and the operating conditions were temperature 40°C and vacuum degree 0.04MPa to obtain a concentrated s...

Embodiment 3

[0076] Extraction of anthocyanins from purple pearl corn kernels

[0077]Use purple pearl purple corn grains as raw materials, dry at 35°C at low temperature, and then crush them into 20-mesh fine powder. Accurately weigh 20.0g of the crushed purple pearl purple corn fine powder and place them in a conical flask. The mixture of 95% ethanol, 0.3mol / L citric acid and distilled water of 4:1:2 is used as the extraction solution, add 100ml of the extraction solution to the Erlenmeyer flask, after mixing evenly, at the extraction temperature of 35°C, the ultrasonic power is 350W Under the assisted action of ultrasonic waves, anthocyanins were extracted from purple pearl purple corn fine powder for 45 minutes; the mixture after ultrasonic assisted extraction was centrifuged at a speed of 10,000 rpm / min for 5 minutes, and then the filter residue and filtrate were separated for secondary extraction , the extraction time is halved, centrifuged again at a speed of 10000rpm / min, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com