Fluorine-containing copolymer for water and oil prevention of paper and preparation method of dispersion liquid of fluorine-containing copolymer

A waterproof and oil-proof, copolymer technology, which is applied in papermaking, water-repellent agent addition, textiles and papermaking, etc. It can solve the problems of poor retention of copolymers and achieve good effect, effect maintenance and good dispersion stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

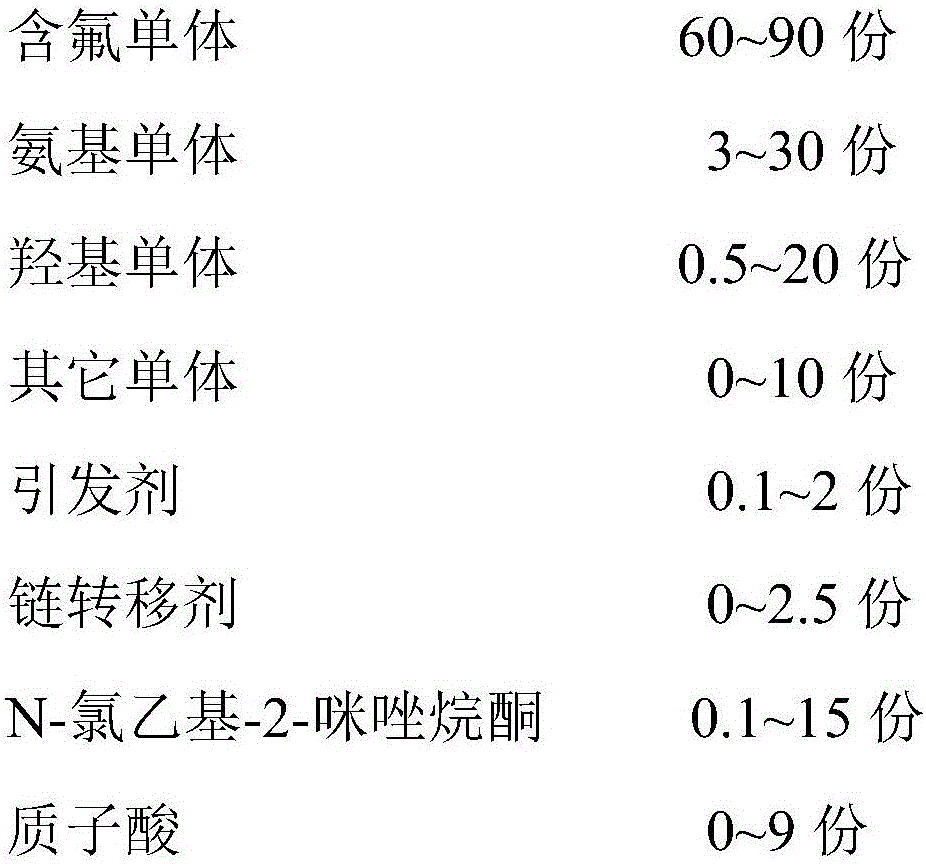

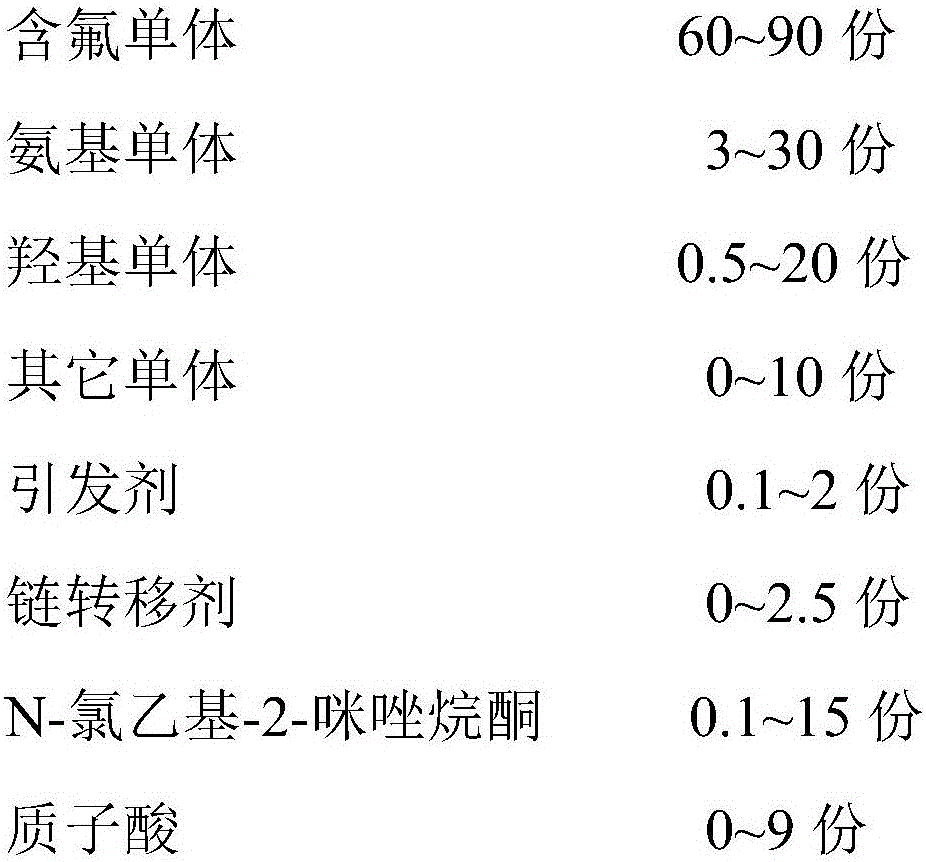

Method used

Image

Examples

Synthetic example 1

[0062] Synthesis example 1 (CH 2 =CHCOOCH 2 CF(CF 3 )[OCF 2 CF(CF 3 )] p OCF 2 CF 2 CF 3 Synthesis, p represents the number of repeating units, and the average value of p is 4)

[0063] Add 961g (1mol) of HOCH to a 1L four-necked reaction flask equipped with a stirrer, a constant temperature oil bath, a thermometer and a condenser 2 CF(CF 3 )[OCF 2 CF(CF 3 )] p OCF 2 CF 2 CF 3 (P average is 4) (purchased from Juhua Group), 79.5g (1.1mol) of CH 2 =CHCOOH (purchased from Suzhou Guanhui Chemical Co., Ltd.), an appropriate amount of water-carrying agent, a small amount of hydroquinone polymerization inhibitor and a small amount of p-toluenesulfonic acid catalyst, heated to 120 ° C for esterification under stirring, and transferred to the water separator When the water in the solution is close to the theoretical value, the esterification reaction is complete. Then, the water-carrying agent and unreacted methacrylic acid are removed by atmospheric distillation and v...

Synthetic example 2

[0064] Synthesis example 2 (CH 2 =C(CH 3 ) COOCH 2 CF(CF 3 )[OCF 2 CF(CF 3 )] p OCF 2 CF 2 CF 3 Synthesis, p represents the number of repeating units, and the average value of p is 10)

[0065] Add 2257g (1mol) of HOCH in a 1L four-necked reaction flask equipped with a stirrer, a constant temperature oil bath, a thermometer and a condenser 2 CF(CF 3 )[OCF 2 CF(CF 3 )] p OCF 2 CF 2 CF 3 (P average is 10) (purchased from Juhua Group), 95g (1.1mol) of CH 2 =C(CH 3 )COOH (purchased from Suzhou Guanhui Chemical Co., Ltd.), an appropriate amount of water-carrying agent, a small amount of hydroquinone polymerization inhibitor and a small amount of p-toluenesulfonic acid catalyst, heated up to 120 ° C for esterification under stirring, and transferred to the water separator When the water in the solution is close to the theoretical value, the esterification reaction is complete. Then, the water-carrying agent and unreacted methacrylic acid are removed by atmospheric...

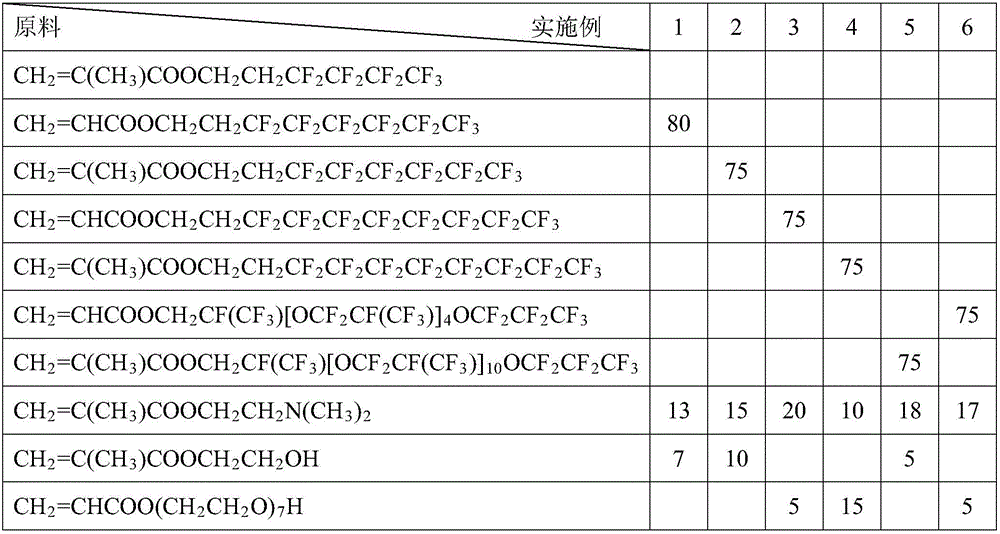

Embodiment 1

[0067] 80 parts by mass of fluorine-containing single CH 2 =CHCOOCH 2 CH 2 CF 2 CF 2 CF 2 CF 2 CF 2 CF 3 , 13 parts by mass CH 2 =C(CH 3 ) COOCH 2 CH 2 N(CH 3 ) 2 (purchased from Shanghai Kangtuo Chemical Co., Ltd.), 7 parts by mass of CH 2 =C(CH 3 ) COOCH 2 CH 2 Add OH, 100 parts by mass of isopropanol, and 1 part by mass of azobisisobutyronitrile into a reactor equipped with a stirrer, a thermometer, and a condenser tube. After purging oxygen with nitrogen, stir and raise the temperature to 70°C, and keep the temperature for 12 hours. After that, 2.6 parts by mass of N-chloroethyl-2-imidazolidinone (purchased from Shanghai Fude Chemical Co., Ltd.) was added, and the reaction was continued for 2 hours. Then add 3.6 mass fractions of acetic acid and 430 mass parts of water, and distill off isopropanol by heating under reduced pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cobb value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com