Preparing method for antioxidant-modified carbon nano tube/hydrogenated butadiene-acrylonitrile rubber

A technology of hydrogenated nitrile rubber and carbon nanotubes, which is applied in the field of preparation of heat-resistant oxygen aging hydrogenated nitrile rubber, antioxidant modified carbon nanotubes/hydrogenated nitrile rubber, can solve the inconvenience of large-scale promotion, and is rarely reported , many environmental protection issues and other issues, to achieve good thermal oxygen aging resistance, simple preparation process, and reduce the effect of self-aggregation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

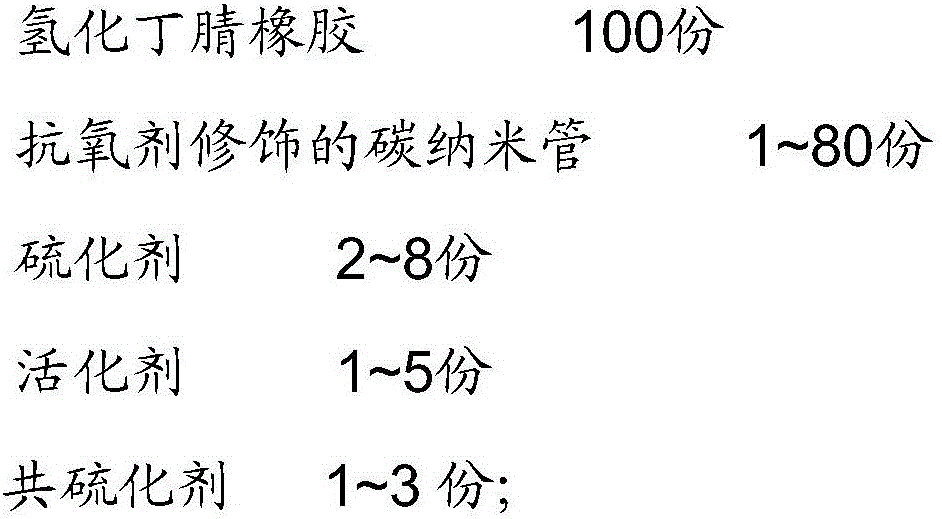

[0031] The preparation method of antioxidant modified carbon nanotube / hydrogenated nitrile rubber of the present invention specifically comprises the following steps:

[0032] (1) Mix concentrated sulfuric acid and concentrated nitric acid, add multi-walled carbon nanotubes (MWCNTS) into the mixed acid, and perform high-temperature reaction. The high-temperature reaction temperature is 70-150°C, and the reaction time is 1-6h. The final carbon nanotubes are washed with water until neutral and dried; wherein the volume ratio of concentrated sulfuric acid and concentrated nitric acid is one of 1:1, 2:1, 3:1 or 4:1. The washing method is one or more of centrifugal washing, suction filtration washing or vacuum distillation.

[0033](2), with the carbon nanotube and antioxidant that step (1) obtains, be 1:0.3-1 by mass ratio, above the fusing point of antioxidant, adopt mechanical force field to mix, and react 30-50min, The product is taken out, and the unreacted antioxidant is was...

Embodiment 1

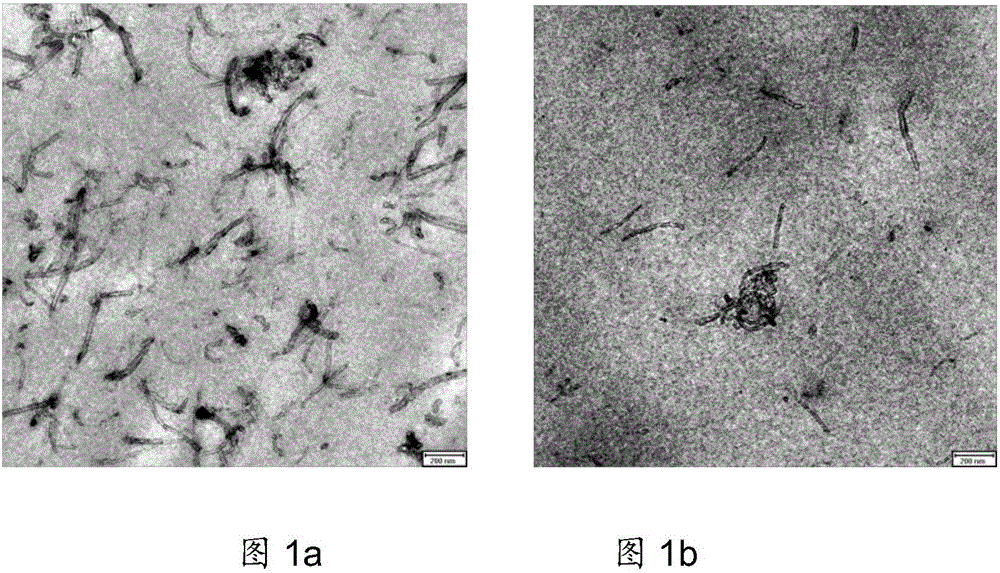

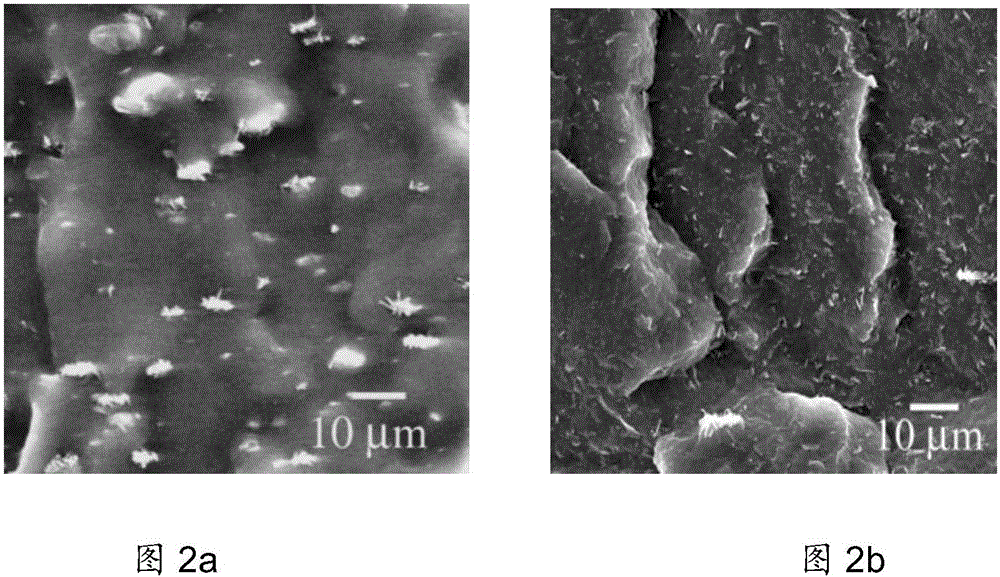

[0043] (1) Preparation of functional carbon nanotubes

[0044] Weigh 120g of multi-walled carbon nanotubes, and simultaneously measure 4500mL of concentrated sulfuric acid and 1500mL of concentrated nitric acid into a 10L beaker, stir mechanically for 30min, transfer the mixture to a 10L three-necked flask, and reflux at 120°C for 3h. After the temperature in the flask dropped to room temperature, the activated carbon nanotubes were centrifuged and washed with a large amount of distilled water until neutral, and placed in a vacuum drying oven at 80° C. for 24 hours. The mass concentrations of concentrated sulfuric acid and concentrated nitric acid are 98% and 68% respectively.

[0045] Weigh 100 g of activated carbon nanotubes and 50 g of hindered phenol AO-80 for pre-mixing, then mechanically mix in a Haake rheometer at 140°C for 30 min, take out the product and cool to room temperature. The cooled product was centrifuged and washed with a large amount of DMF, and then conti...

Embodiment 2

[0054] (1) Preparation of functional carbon nanotubes

[0055] Weigh 120g of multi-walled carbon nanotubes, and simultaneously measure 4500mL of concentrated sulfuric acid and 1500mL of concentrated nitric acid into a 10L beaker, stir mechanically for 30min, transfer the mixture to a 10L three-necked flask, and reflux at 120°C for 1h. After the temperature in the flask dropped to room temperature, the activated carbon nanotubes were centrifuged and washed with a large amount of distilled water until neutral, and placed in a vacuum drying oven at 80° C. for 24 hours. The mass concentrations of concentrated sulfuric acid and concentrated nitric acid are 98% and 68% respectively.

[0056] Weigh 100 g of activated carbon nanotubes and 50 g of hindered phenol AO-80 for pre-mixing, mechanically mix in a Haake rheometer at 150°C for 50 min, take out the product and cool to room temperature. The cooled product was centrifuged and washed with a large amount of DMF, and then continued ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com