ABS/PLA (acrylonitrile-butadiene-styrene/poly lactic acid) light-emitting composite material for 3D (three-dimensional) printing

A composite material, 3D printing technology, applied in the direction of additive processing, etc., to achieve the effect of broadening the scope of application, excellent mechanical and electrical properties, and good luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

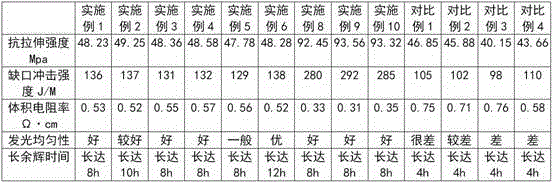

Examples

Embodiment 1

[0023]1. Pretreatment of polylactic acid raw materials: crush polylactic acid raw materials (D, L-polylactic acid raw materials, weight average molecular weight 100,000) into 300 mesh powders, disperse them in pure water, and ultrasonicate (power 250W) for 1 hour, while ultrasonically Microwave irradiation (2800MHz, temperature controlled at 85°C) for 1 hour; stop ultrasonic and microwave irradiation, wash, discharge, and dry to obtain pretreated polylactic acid;

[0024] 2. Preparation of PLA / carbon material masterbatch: Weigh 9.7 parts of carbon nanotubes and place them in a beaker, add chloroform, stir at high speed (1200r / min), and ultrasonic (power 400KW) for 3 hours to obtain a suspension of carbon nanotubes. Standby; at a heating temperature (60°C), dissolve 20 parts of pretreated polylactic acid in an organic solvent to obtain a polylactic acid solution, which is divided into two to obtain the first and second parts of polylactic acid solution, for later use; constant t...

Embodiment 2

[0029] Based on the preparation method of embodiment 1, the difference is only in:

[0030] Graphene / SiO 2 / Phosphor powder is prepared by the following method: disperse graphene in ethanol with ultrasonic stirring (700KW ultrasonic vibration and 1300r / min centrifugal speed stirring); then add a certain proportion (3:1) of water and ammonia water, stir well and then add normal The mass ratio of ethyl silicate to graphene is 1.8:1, the pH value is adjusted to 9, the reaction temperature is 25°C, and the reaction is carried out for 12 hours; centrifuged and washed with acetone and deionized water for 3 times to obtain a precipitate; the precipitate at 90 o Dry at C for 5h to obtain SiO-coated 2 The core-shell composite material; the coating with SiO 2 The core-shell composite material was heat-treated at 800°C for 1.5 h in an argon atmosphere; the heat-treated core-shell composite material was immersed in hydrofluoric acid for 15 min to remove part of the silica, centrifuged...

Embodiment 3

[0032] Based on the preparation method of embodiment 1, the difference is only in:

[0033] Graphene / SiO 2 / Phosphor powder is prepared by the following method: disperse graphene in ethanol with ultrasonic stirring (700KW ultrasonic vibration and 1300r / min centrifugal speed stirring); then add a certain proportion (3:1) of water and ammonia water, stir well and then add normal The mass ratio of ethyl silicate to graphene is 1.8:1, the pH value is adjusted to 9, the reaction temperature is 25°C, and the reaction is carried out for 12 hours; centrifuged and washed with acetone and deionized water for 3 times to obtain a precipitate; the precipitate at 90 o Dry at C for 5h to obtain SiO-coated 2 The core-shell composite material; the coating with SiO 2 The core-shell composite material was heat-treated at 800°C for 1.5 h under an argon atmosphere; the heat-treated core-shell composite material was immersed in hydrofluoric acid for 30 min to remove part of the silica, centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com