Double-shell-microcapsule thermal-insulation water-based coating and preparation method thereof

A double-layer shell, microcapsule technology, applied in microcapsule preparation, microsphere preparation, reflection/signal coating, etc., to achieve the effect of good dispersion, less agglomeration and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

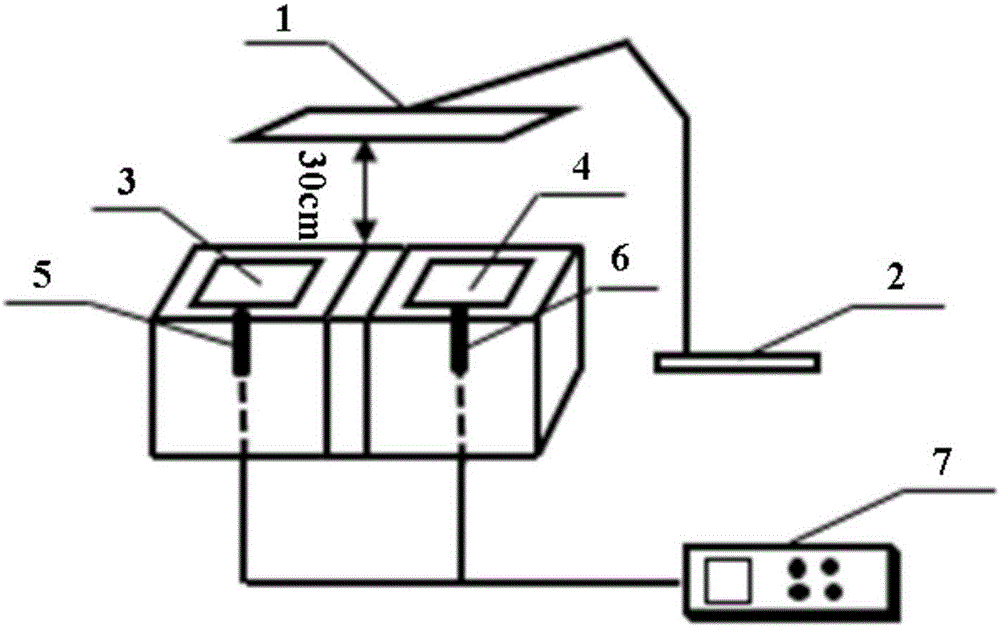

Method used

Image

Examples

Embodiment 1

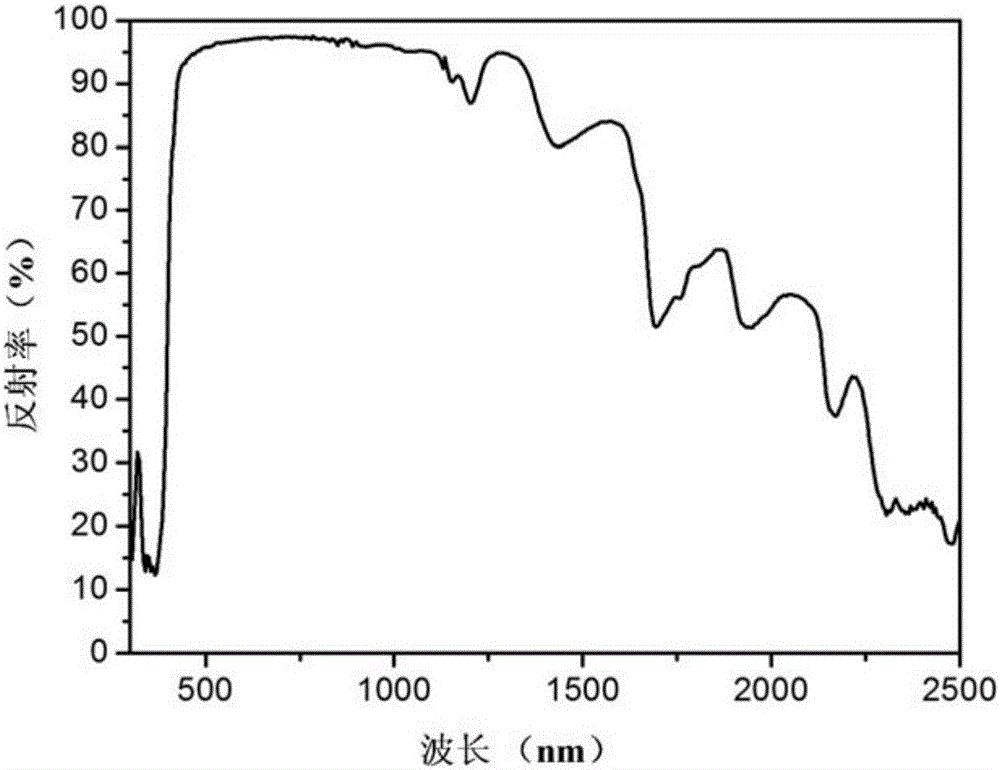

[0031] Thermal insulation coating based on nano titanium dioxide powder and titanium dioxide / polymethyl methacrylate phase change temperature control microcapsules. The composition of the coating includes: water 45g, emulsion 45g, and titanium dioxide powder with an average particle size of 150 nanometers (R- 218) 4g, titanium dioxide / polymethyl methacrylate phase change temperature control microcapsules with an average particle size of 1 micron, the mass of 1g, polyurethane modified polyether thickener (SN-621N) 3g, multifunctional additives (AMP -95) 0.6g, defoamer (NXZ) 0.3g, anti-mold agent (ROCIMA342) 0.2g, anti-aging agent (Chimassorb 81) 0.2g. The preparation method is as follows:

[0032] First, add a polyacrylic acid dispersant with a weight average molecular weight of 20,000 to the water to adjust the pH of the solution to 3 to 5; then add the thermal insulation functional filler, the mass fraction of the thermal insulation functional filler is 8%, the dispersant and th...

Embodiment 2

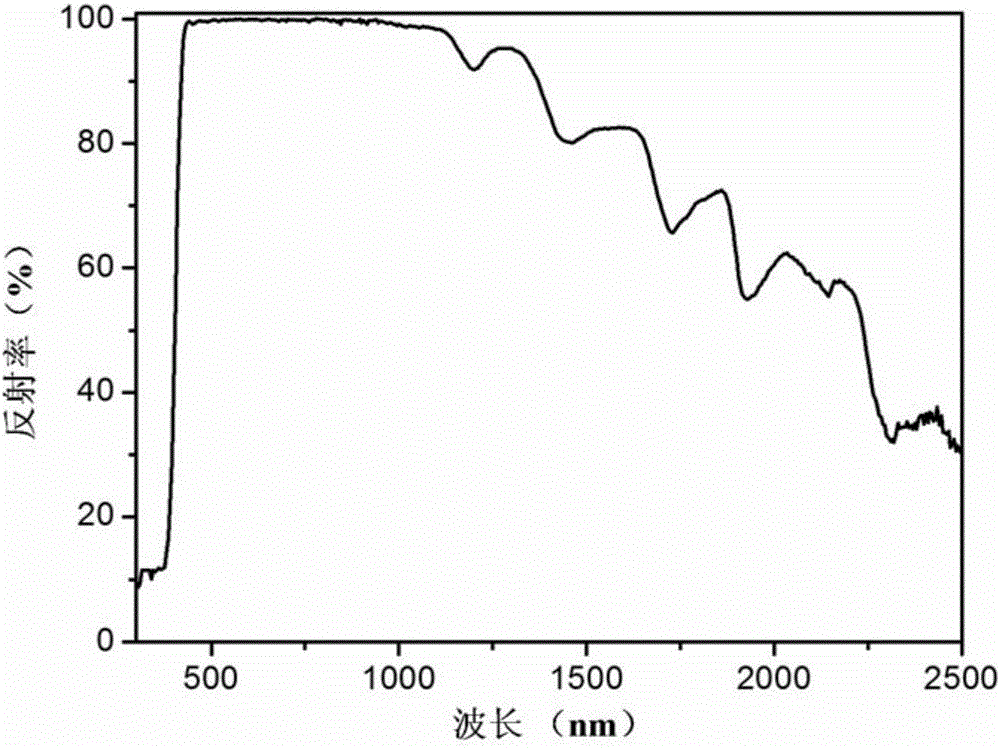

[0038] Thermal insulation coating based on nano zirconia powder and zirconia / polymethyl methacrylate phase change temperature control microcapsules. The composition of the coating includes: 20g water, 35g emulsion, and zirconia powder with an average particle size of 250 nanometers 24g, zirconia / polymethyl methacrylate phase change temperature control microcapsules with an average particle size of 15 microns, 6g, polyurethane modified polyether thickener (SN-621N) 0.1g, multifunctional additives (AMP-95) ) 0.4g, defoamer (NXZ) 0.2g, antifungal agent (ROCIMA 342) 0.2g, anti-aging agent (Chimassorb 81) 0.3g. The preparation method is as follows:

[0039] First, add ammonium polyacrylate dispersant with a weight average molecular weight of 40,000 to the water to adjust the pH of the solution to 3-5; then add the heat-insulating functional filler, stir and react at 70-90°C for 0.5-2 hours; the quality of the heat-insulating functional filler The fraction is 15%, and the mass ratio o...

Embodiment 3

[0045] Thermal insulation coating based on nano tin oxide powder and tin oxide / methyl methacrylate and methacrylic acid copolymer phase change temperature control microcapsules. The composition of the coating includes: 30g water, 40g emulsion, and an average particle size of 350 nanometers 18g of tin oxide powder, 2g of tin oxide / methyl methacrylate and methacrylic acid copolymer phase change temperature control microcapsules with an average particle size of 15 microns, polyurethane modified polyether thickener (SN-612N) 0.5 g. Multifunctional auxiliary agent (AMP-95) 0.5g, defoamer (NXZ) 0.25g, antifungal agent (ROCIMA 342) 0.25g, anti-aging agent (Chimassorb 81) 0.2g. The preparation method is as follows:

[0046] First, add a polyvinyl alcohol dispersant with a weight average molecular weight of 30,000 to the water to adjust the pH of the solution to 3-5; then add heat-insulating functional fillers, and stir for 0.5-2 hours at 70-90°C; among them, the heat-insulating function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com