Method and apparatus for producing biomass fuel by using urban waste

A biomass fuel and waste technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of failure to reuse food waste resources, lack of effective treatment and disposal methods, and lack of disposal methods, so as to avoid environmental problems. The effect of secondary pollution, ensuring product calorific value and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

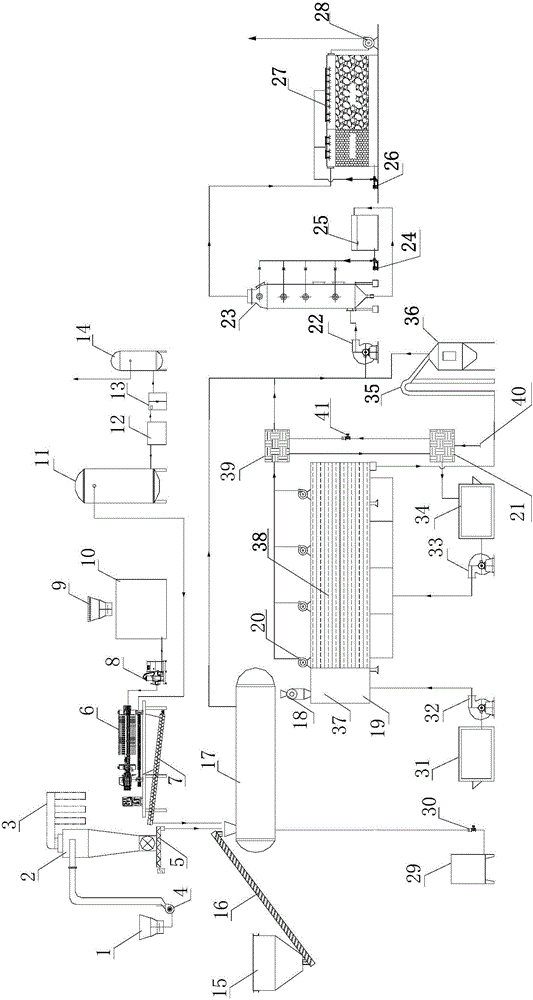

[0022] refer to figure 1 , which is a device for producing biomass fuel from municipal waste, including a biomass treatment device, a kitchen waste treatment device, a sludge treatment device, a stirring reactor 17, an extrusion molding machine 18, a high-temperature section 37 and a low-temperature Belt dryer 19, first heat exchanger 21, second heat exchanger 39, cooler 36, drug storage tank 29, high-temperature hot blast stove 31, low-temperature hot blast stove 34, washing tower 23, biological deodorization device 27 in section 38 , wherein the biomass treatment device includes a biomass crusher 1, a biomass bin 2, a bag filter 3, a third induced draft fan 4, and a shaft quantitative conveyor 5, and the bottom discharge of the biomass crusher 1 passes through the third induced draft fan 4 into the biomass bin 2, the bag filter 3 is set on the top of the biomass bin 2, and the bottom of the biomass bin 2 is sent to the entrance of the stirring reactor 17 through the shaft qu...

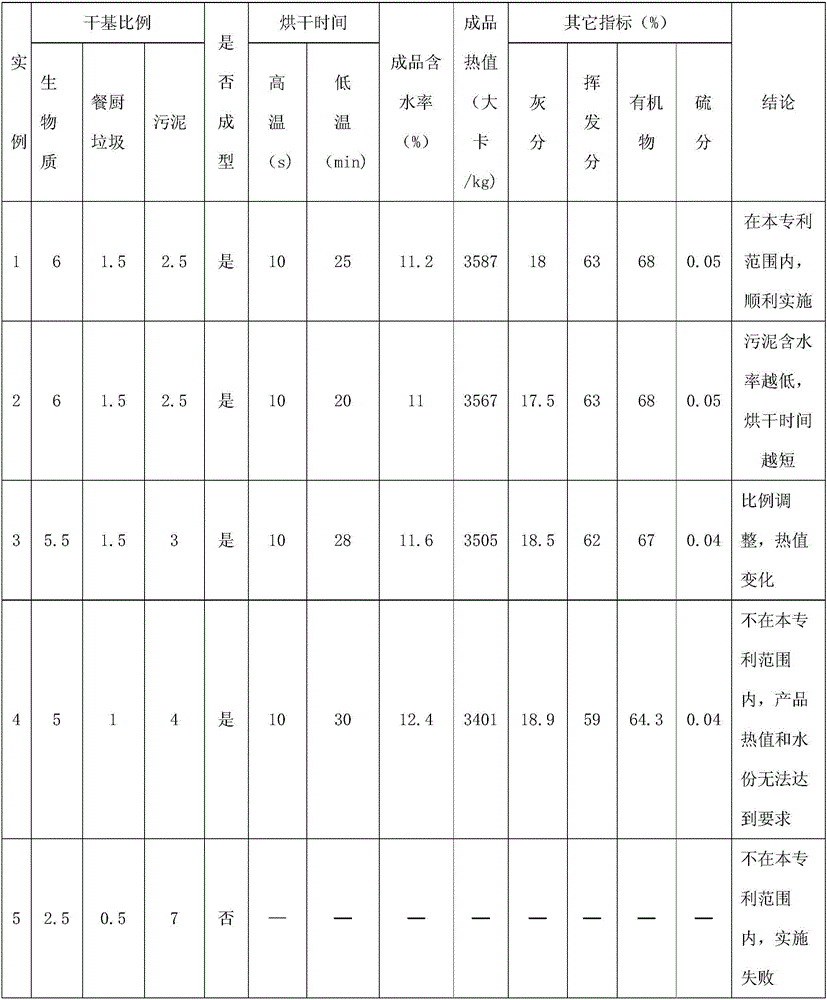

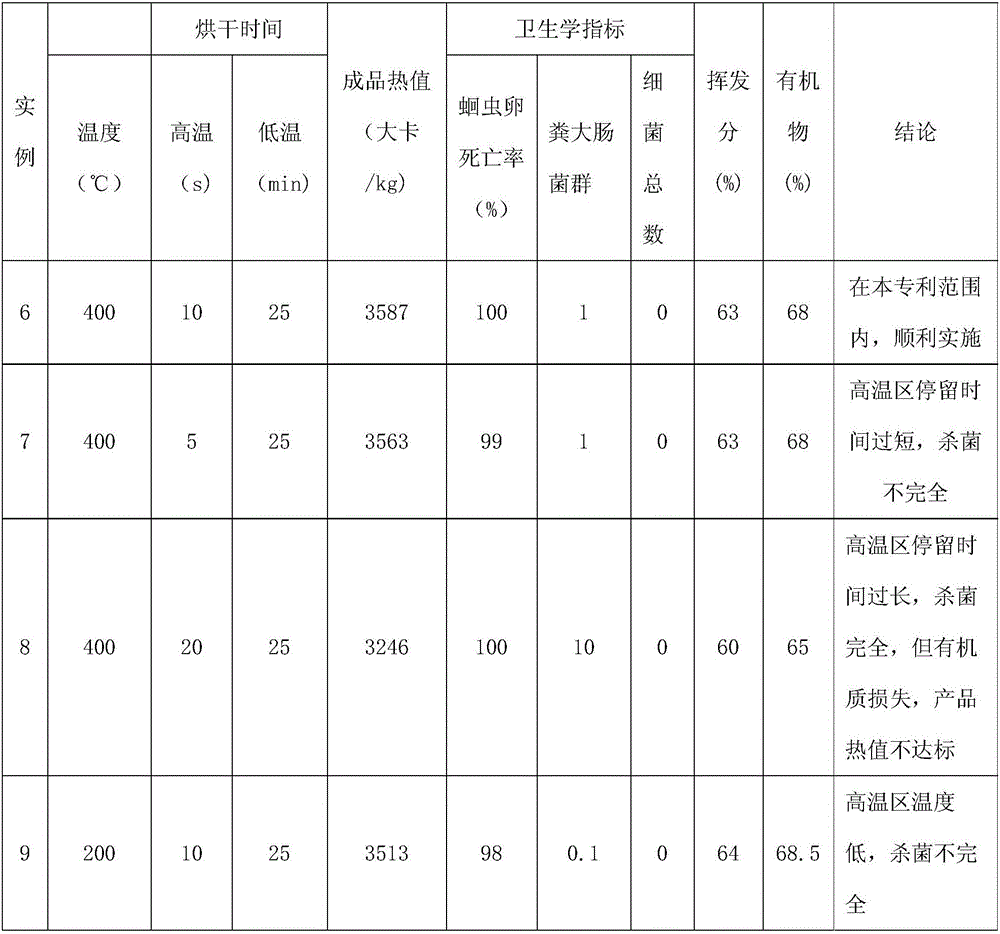

experiment example 1

[0037] A method for producing biomass fuel from municipal waste, comprising the steps of:

[0038] ①. The wastes produced by urban landscaping, such as dead branches, leaves, hay, straw, wood, sawdust, etc., are sorted to remove plastic and metal, and then crushed. Take 60 parts for later use. At this time, the water content of the biomass The rate is 40%;

[0039] ②. After the food waste is sorted to remove plastic and metal, it is crushed, and injected into the ultra-high pressure filter press 6 by a high-pressure plunger pump to carry out pressure filtration and dehydration. After the pressure filtration and dehydration, the moisture content of the material is 40%. After crushing, Take 15 spares;

[0040] 3. Get 75 parts of sludge with a moisture content of 80% and drop into the stirring reactor 17 through pretreated kitchen waste and biomass to carry out strong mixing, and add deodorant (ecological enzyme, dosage 0.001- 0.005L / kg.DS);

[0041] ④, the mixed material is s...

experiment example 2

[0045] A method for producing biomass fuel from municipal waste, comprising the steps of:

[0046] ①. The wastes produced by urban landscaping, such as dead branches, leaves, hay, straw, wood, sawdust, etc., are sorted to remove plastic and metal, and then crushed. Take 60 parts for later use. At this time, the water content of the biomass The rate is 40%;

[0047] ②. After the food waste is sorted to remove plastic and metal, it is crushed, and injected into the ultra-high pressure filter press 6 by a high-pressure plunger pump to carry out pressure filtration and dehydration. After the pressure filtration and dehydration, the moisture content of the material is 40%. After crushing, Take 15 spares;

[0048] 3. Get 37.5 parts of sludge with a moisture content of 60% and put into the stirring reactor 17 through pretreated kitchen waste and biomass to carry out strong mixing, and add deodorant (ecological enzyme, dosage 0.001- 0.005L / kg.DS);

[0049] ④, the mixed material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com