Method for improving wine quality by use of wine lees aging technology

A wine and wine lees technology, applied in the field of wine brewing, can solve the problems of unpleasant lees taste, increased labor and cost, and insignificant aging effect of wine, so as to achieve the roundness of wine body and the enhancement of tannin structure, and the overall quality improvement , Improve the effect of antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

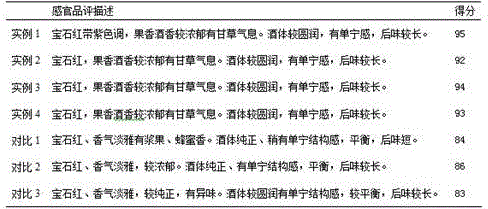

Examples

Embodiment 1

[0032] A method for improving wine quality by using lees aging technology, adopting the following steps:

[0033] (1) Cabernet Sauvignon grapes are artificially threshed and crushed to obtain grape must;

[0034] (2) Add activated yeast BDX to the grape must prepared in step (1), ferment at 26-30°C, ferment with the skins on for 7 days, separate the skins and remove the skins; the amount of yeast BDX added Add 0.25g per liter of grape must;

[0035] (3) Continue to ferment the above-mentioned fermentation broth at a fermentation temperature of 22-26°C. When the sugar content is lower than 4g / L, the main fermentation ends, and the wine lees and clarified liquor are separated after precipitation with wine lees;

[0036] (4) Collect the fine wine lees on the upper part of the wine lees in step (3), and add sulfurous acid to the fine wine lees; the amount of sulfurous acid added is 40 mg per liter of fine wine lees;

[0037] (5) Add the fine wine lees containing sulfurous acid o...

Embodiment 2

[0043] A method for improving wine quality by using lees aging technology, adopting the following steps:

[0044] (1) Cabernet Sauvignon grapes are artificially threshed and crushed to obtain grape must;

[0045] (2) Add activated yeast L2323 to the grape mash prepared in step (1), ferment at 26-30°C, ferment with skins for 10 days, separate skin dregs, and collect fermentation liquid; the amount of yeast L2323 added Add 0.25g per liter of grape must;

[0046] (3) Continue to ferment the above-mentioned fermentation broth at a fermentation temperature of 22-26°C. When the sugar content is lower than 4g / L, the main fermentation ends, and the wine lees and clarified liquor are separated after precipitation with wine lees;

[0047] (4) Collect the fine wine lees on the upper part of the wine lees in step (3), and add sulfurous acid to the fine wine lees; the amount of sulfurous acid added is 50 mg per liter of fine wine lees;

[0048] (5) Add the fine wine lees containing sulfu...

Embodiment 3

[0054] A method for improving wine quality by using lees aging technology, adopting the following steps:

[0055] (1) Cabernet Sauvignon grapes are artificially threshed and crushed to obtain grape must;

[0056] (2) Add activated yeast D254 to the grape mash prepared in step (1), ferment at 26-30°C, ferment with skins for 8 days, separate skin dregs, and collect fermentation liquid; the amount of yeast D254 added Add 0.3g per liter of grape must;

[0057] (3) Continue to ferment the above-mentioned fermentation broth at a fermentation temperature of 22-26°C. When the sugar content is lower than 4g / L, the main fermentation ends, and the wine lees and clarified liquor are separated after precipitation with wine lees;

[0058] (4) Collect the fine wine lees on the upper part of the wine lees in step (3), and add sulfurous acid to the fine wine lees; the amount of sulfurous acid added is 45 mg per liter of fine wine lees;

[0059] (5) Add the fine wine lees containing sulfurous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com