Fermentation compounding device for microbial cellulose and base material and technology of fermentation compounding device

A technology of microbial cellulose and composite equipment, which is applied in the composite field of microbial cellulose fibers and other materials to achieve the effects of good water resistance, tight connection and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

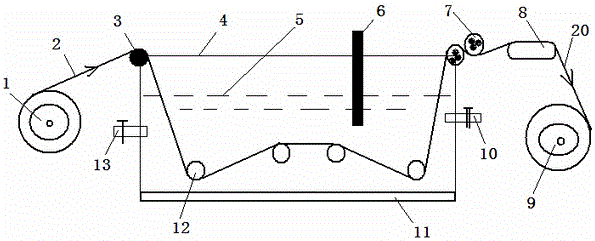

[0028] Such as figure 1 The fermentation composite equipment of microbial cellulose and substrate shown in the figure has substrate unwinding device 1, introduction roller 3, fermentation composite box 4, pinch roller 7, drying and inactivation Device 8, composite coil winding device 9; the interior of the fermentation composite box 5 stores the mixed slurry of microbial strains and cellulose stock solution, and the mixed slurry also contains business liquid necessary for the survival or reproduction of microbial strains.

[0029] The substrate 2 is paper made of long plant fibers, or silk threads of cotton, hemp or chemical fibers or their non-woven fabrics or woven fabrics.

[0030] The interior of the fermentation compound box 5 is provided with a plurality of guide rollers 12 that are parallel to each other and perpendicular to the walking direction of the substrate, so that the substrate 2 is drawn through the mixed slurry in the fermentation compound box 4; while the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com