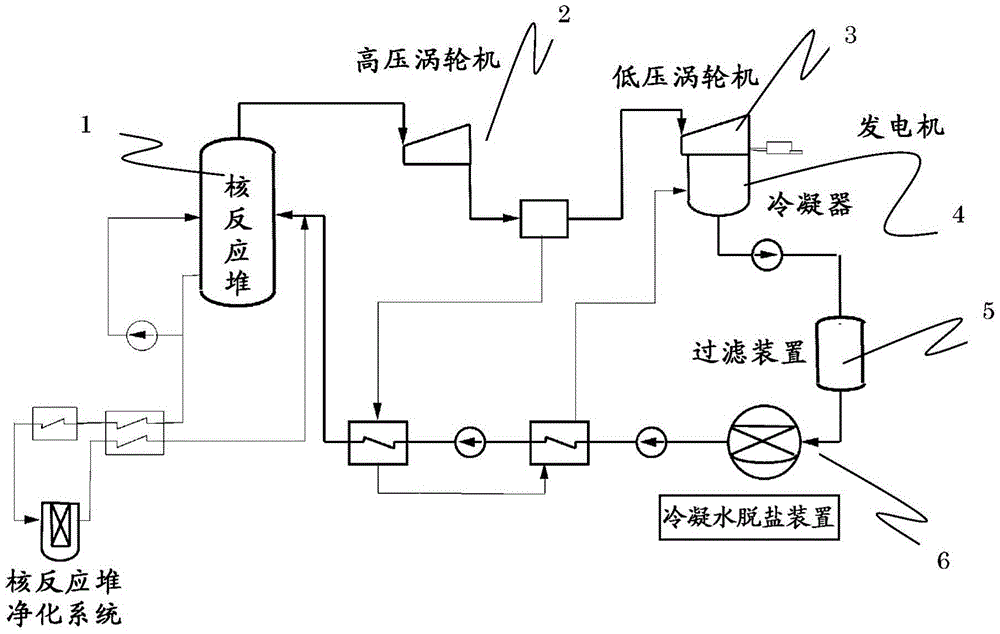

Condensate demineralization apparatus and condensate demineralization method

A desalination device and technology for condensed water, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

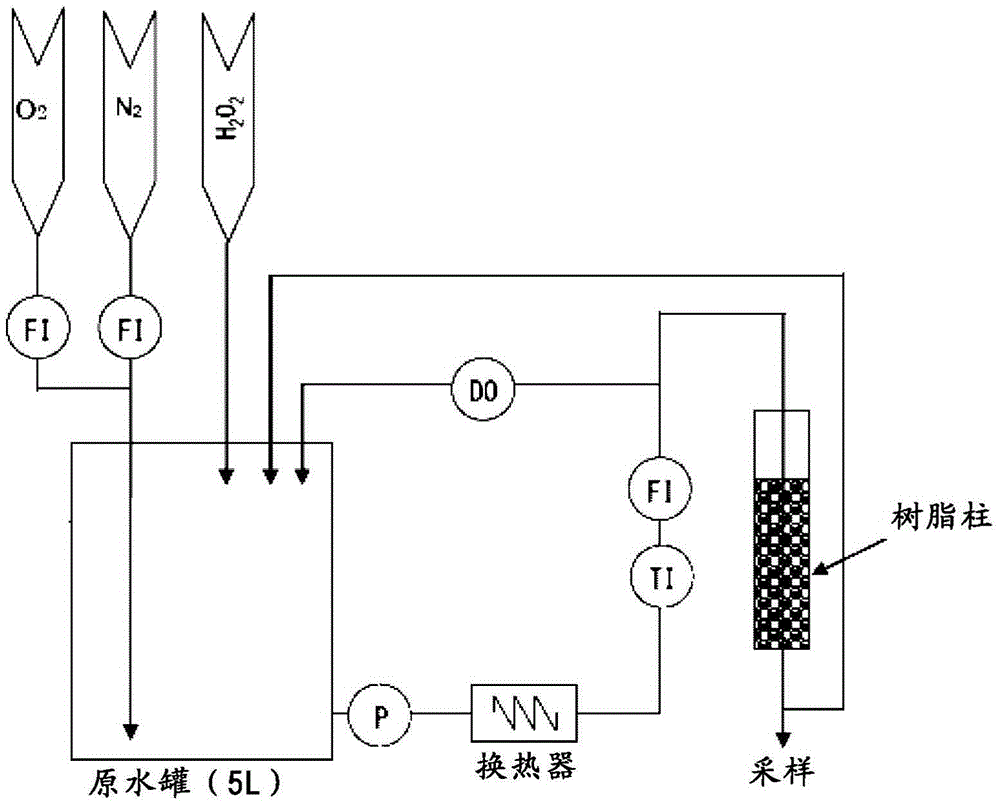

[0042] use figure 2 The closed-loop test device shown (in the figure, "P" represents a pump, "DO" represents a dissolved oxygen meter, "FI" represents a flow meter, and "TI" represents a thermometer) circulates into the resin column in the raw water tank ( tank) hydrogen peroxide (H 2 o 2 ) concentration adjusted to 5mg / L, the TOC (total organic carbon) dissolved from the ion exchange resin was concentrated in the system, the concentration of the TOC was measured over time, and the dissolution rate of TOC from the ion exchange resin was measured. evaluate. The measurement of the TOC concentration was performed using a total organic carbon analyzer (TOC-V manufactured by Shimadzu Corporation). The main test conditions are as follows.

[0043] ·Column inner diameter: 25mmΦ

[0044] ·Water linear velocity: 40m / h

[0045] ·Temperature of treated water (pure water): 40°C

[0046] ·Hydrogen peroxide concentration: 5mg / L

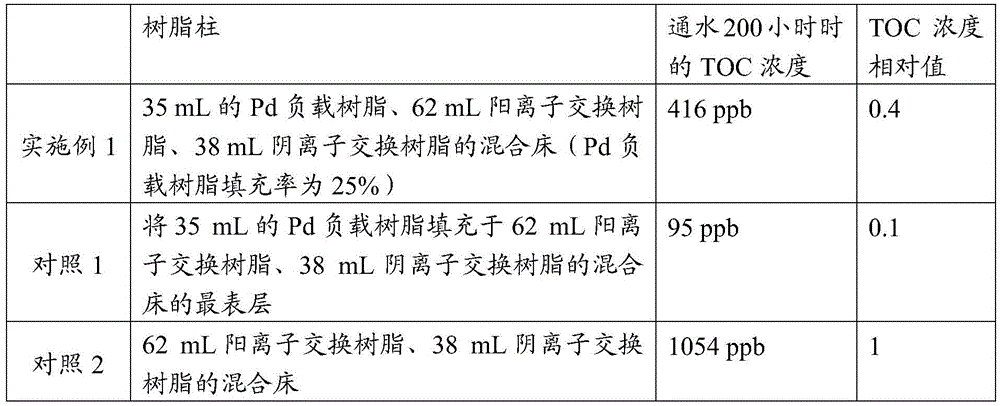

[0047] As the resin column, three types of resin col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com