Polymerizable quantum dot and application thereof

A quantum dot, polymer-based technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of reducing the optical properties of quantum dot packages, difficult to increase the concentration of quantum dots, easy to contact with water or oxygen, etc. Optical properties and quantum efficiency, good optical properties, high concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also proposes a method for preparing a quantum dot package, comprising the following steps;

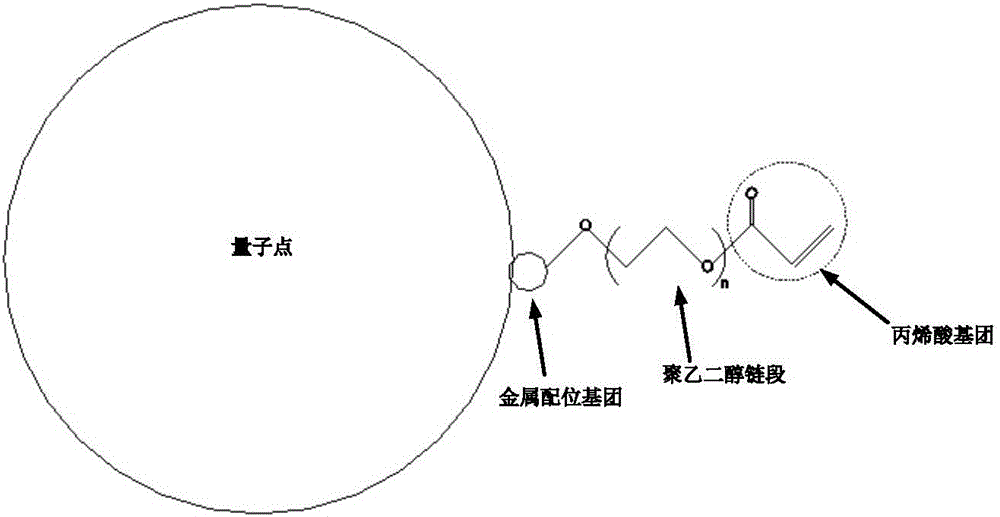

[0068] S1: Introduce polymerizable groups on the surface of quantum dots to form quantum dot composites;

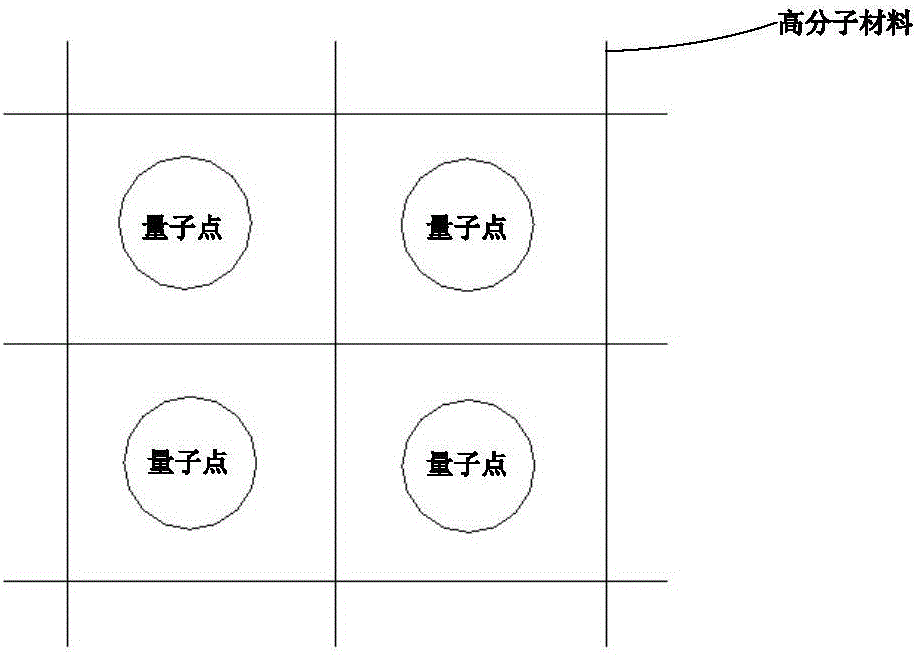

[0069] S2: Mix the quantum dot composite with the liquid polymer material precursor, and the polymer material precursor can undergo polymerization reaction after being initiated by the initiator;

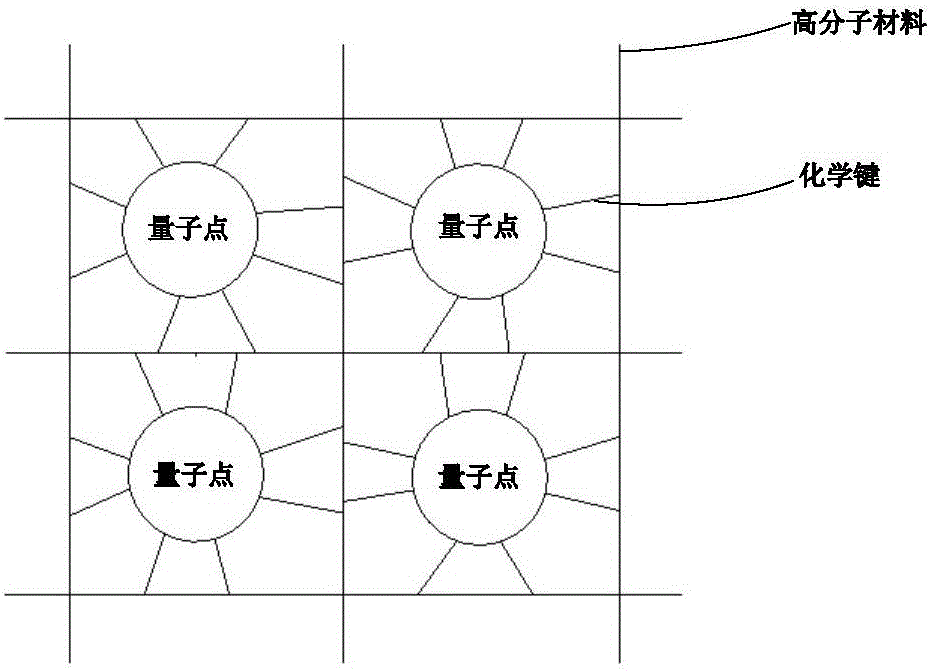

[0070] S3: Initiate the polymerization reaction of the precursor of the polymer material by means of light or heating, and solidify into a polymer material. During the polymerization process, part of the precursor of the polymer material and the polymerizable group undergo a copolymerization reaction, so that the quantum dots and the polymer The materials are held together by covalent bonds.

[0071] In the preparation method of the present invention, the polymerizable group on the surface of the quantum dot can undergo a polymerization reaction with the p...

Embodiment 1

[0085] Preparation of quantum dot ligand SH-CO-O-PEG-O-CO-CH=CH2

[0086] Get 50mmol PEG400 and 25mmol dithiodipropionic acid and join in the reaction container, and add 100ml dichloromethane, 30ml diisopropylmethanol and 16.2g 4-dimethylaminopyridine-p-toluenesulfonate, at room temperature Esterification reaction occurred, stirred at room temperature for 24 hours; the resulting product was passed through argon for 30 minutes at 0°C, added 100mol triethylamine for 30 minutes, slowly added 10mmol of acryloyl chloride dropwise under an argon atmosphere at 0°C, and continued to stir for 24 hours; Wash and extract three times with saturated sodium chloride aqueous solution. If the emulsification is severe, separate the two phases by centrifugation. Dry the extracted organic phase with saturated sodium sulfate and remove the solvent by rotary evaporation to obtain a viscous liquid; add 100ml volume ratio to the viscous liquid 4:1 water and ethanol, then add 2g sodium borohydride, s...

Embodiment 2

[0092] The difference from Example 1 is that when preparing the quantum dot package, a chloroform solution of a quantum dot composite containing 50 mg of quantum dots and 500 mg of acrylic UV glue were taken.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com