Method for preparing S-cyanohydrin

A technology of cyanohydrin and acetone cyanohydrin, applied in the direction of fermentation, etc., can solve the problems of difficult industrial application, low enzyme utilization rate, low product efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] In the present invention, the preparation method of preferably immobilized cyanohydrin lyase comprises:

[0087] Adsorption

[0088] A method of immobilizing the enzyme by adsorbing cyanohydrin lyase or cells containing cyanohydrin lyase on its surface by using various adsorbents. Usually there are physical adsorption and ion adsorption.

[0089] Commonly used adsorbents include activated carbon, alumina, diatomaceous earth, porous ceramics, porous glass, etc.

[0090] The adsorption method is used to immobilize the enzyme, which is easy to operate, mild in conditions, does not cause enzyme denaturation or inactivation, and the carrier is cheap and easy to obtain, and can be used repeatedly.

[0091] carrier binding

[0092] The most commonly used method is the covalent binding method, that is, the non-essential group of the cyanohydrin lyase forms an irreversible connection with the carrier through a covalent bond. Protein groups that can be coupled under mild cond...

Embodiment 1

[0115] Construction of embodiment 1 mutant

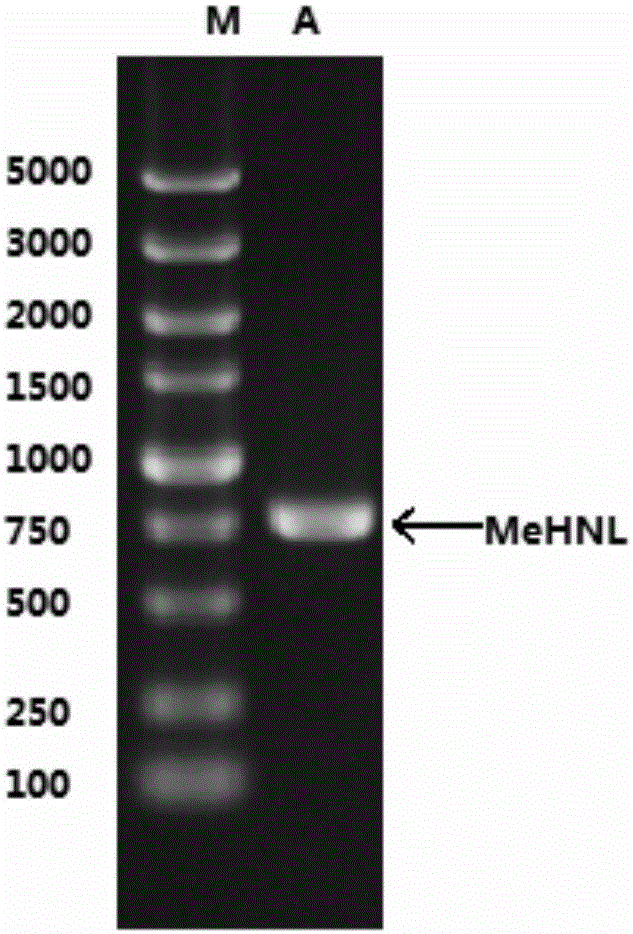

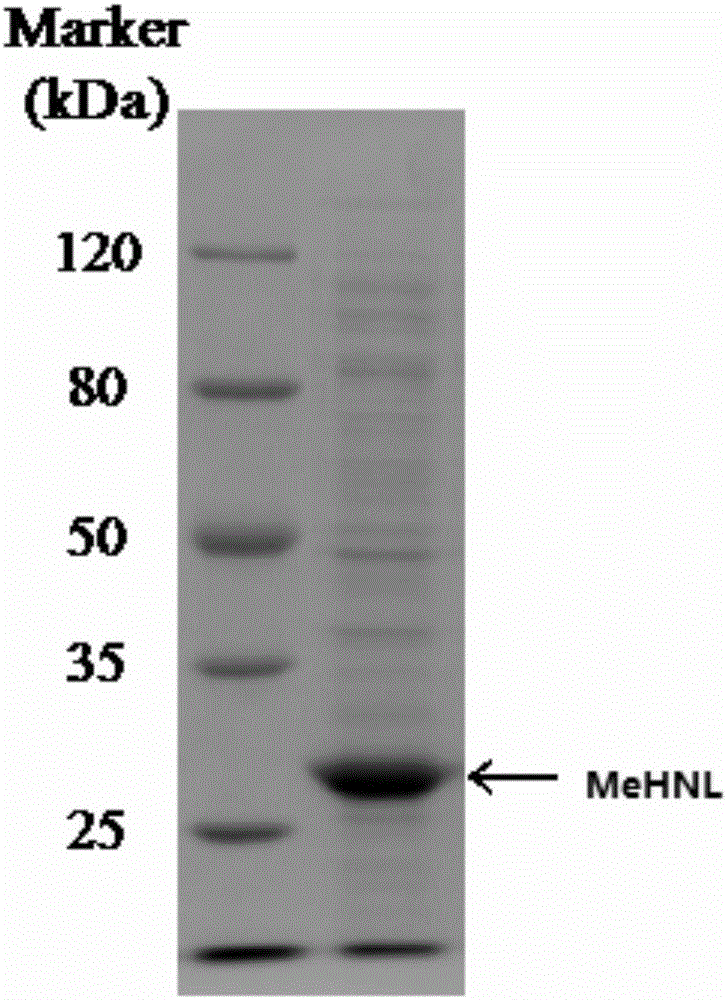

[0116] According to the protein sequence 1 (SEQ ID NO.: 1) of MeHNL reported by Wajant, according to the codon preference of Escherichia coli, MeHNL DNA sequence 2 (SEQ ID NO.: 2) was synthesized and cloned into plasmid pET28 (purchased from Invitrogene company) NdeI-HindIII site. Using the plasmid as a template, primers were designed, see sequence 3 and sequence 4. Using a random mutagenesis kit, by changing the MnSO 4 concentration to carry out multiple reactions, thereby introducing 1 to 3 point mutations into the MeHNL gene, so that 1-3 amino acids in the amino acid sequence of the MeHNL enzyme are replaced. To amplify the enzyme encoding MeHNL, primers SEQ ID No.3 and SEQ ID No.4 were used as forward and reverse primers, respectively. Both primers contained sites compatible with the PCR-amplified MeHNL gene fragment obtained by site-directed recombination cloning using Gateway Technology. The gel electrophoresis profile of ...

Embodiment 2

[0125] Example 2 strain construction and high-density fermentation

[0126] Synthesize a tryptophan promoter containing sequence 6 (SEQ ID NO.: 6), and connect it to the NcoI and NdeI sites of pET28a, and then connect the coding polynucleotides of sequence 1 and 5 in Example 1 to the aforementioned The NdeI-XhoI site of the Escherichia coli plasmid pTrp2-MeHNL1 and pTrp2-MeHNL5 containing the tandem tryptophan promoter (plasmid map as shown in Figure 4 shown). The plasmid was transformed into Escherichia coli JM109 (purchased from Invitrogene), and the corresponding strains were obtained on Kana resistance plates, inoculated into LB medium, cultured overnight at 37°C, and preserved with 20% glycerol.

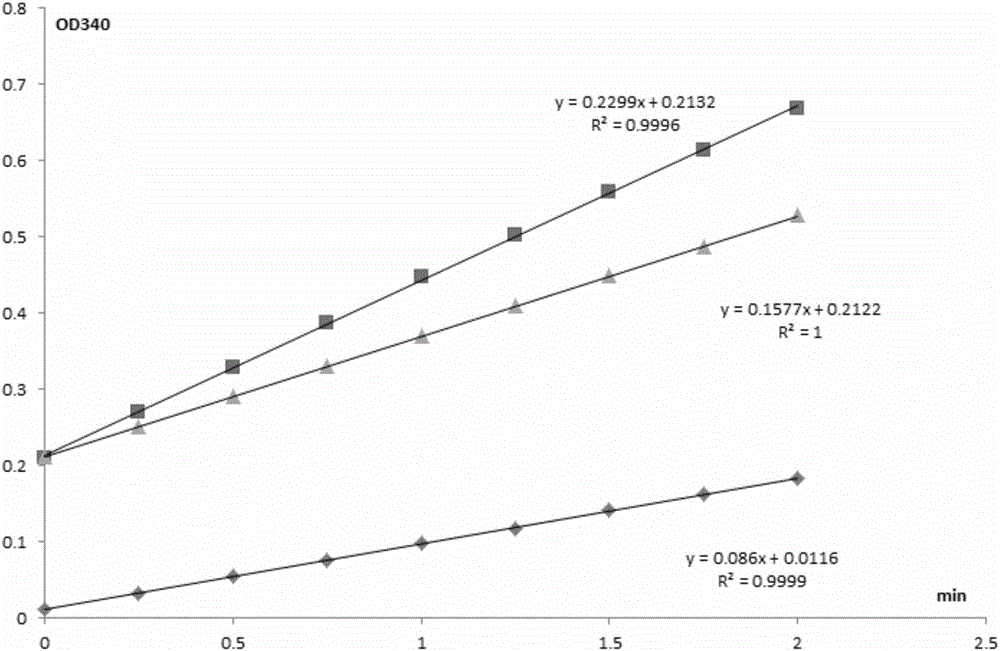

[0127] The strains were inoculated in a 1L shake flask filled with 200mL LB medium, and cultured at 37°C, 180-220rpm for 10-16h. The above-mentioned cultivated seeds were inoculated in a 3L upper tank fermentation medium (M9) in a ratio of 10% (v / v) (glucose 4g / L, disodium hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com