Carbon dioxide capturing and liquefying process stepwise utilizing smoke waste heat

A carbon dioxide and flue gas waste heat technology, applied in the field of separation, can solve problems such as increasing the complexity of the process, and achieve the effect of avoiding adsorption and dehydration units, reducing dehydration requirements, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

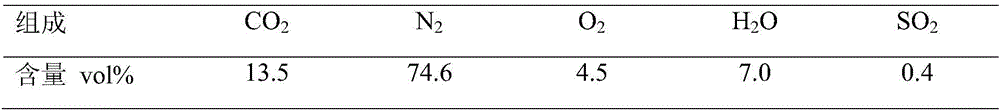

[0024] Table 1 Average composition of flue gas in a 600MW coal-fired power plant

[0025]

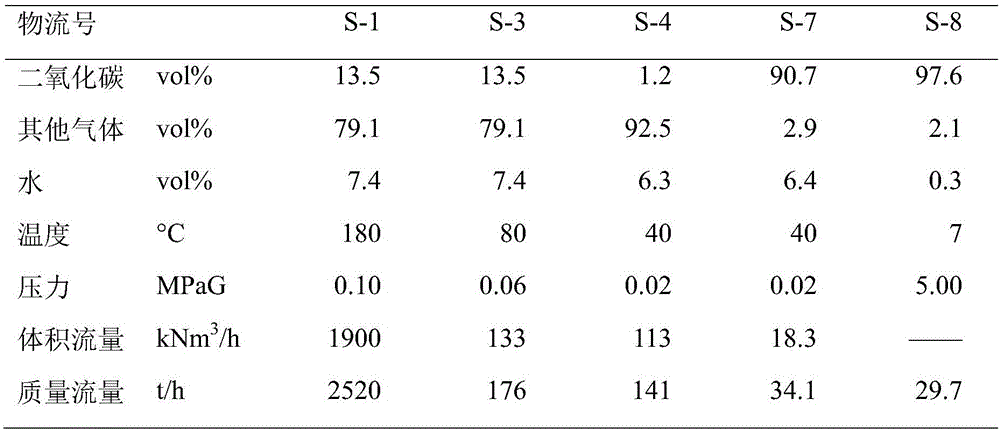

[0026] This embodiment is aimed at the flue gas (flow rate 190×10 4 N m 3 / h, the content of carbon dioxide is 13.5vol%, and the temperature is 180°C), the carbon dioxide capture liquefaction process of the present invention is adopted, and the waste heat of the flue gas is used in stages to separate the carbon dioxide from part of the flue gas to produce liquid crude carbon dioxide.

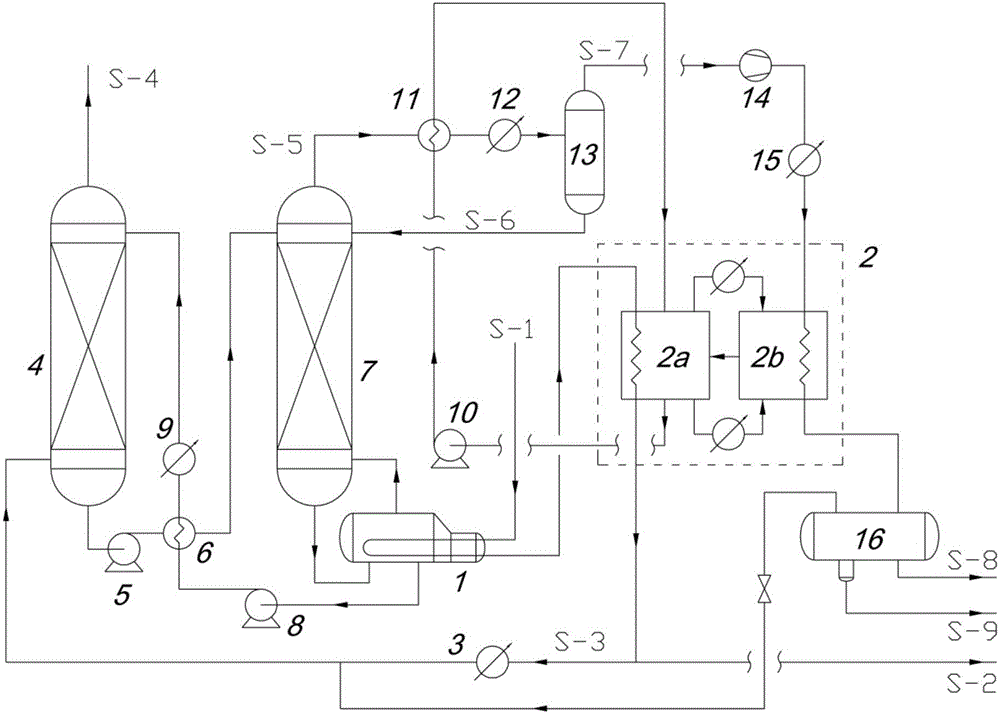

[0027] Such as figure 1 As shown, flue gas S-1 pretreated by dust removal, desulfurization, denitrification, etc., is sent to the reboiler 1 by the blower, and exchanges heat with the absorbent to be regenerated; then, it enters the steam generator 2a of the absorption refrigeration system 2 , exchange heat with the dilute solution in the refrigeration system; subsequently, a part of S-2 is directly discharged into the atmosphere, and another part of S-3 enters the first cooler 3, and enters the absor...

Embodiment 2

[0033] Table 3 Average composition of flue gas in a 500MW coal-fired power plant (excessive air control)

[0034]

[0035] This embodiment is aimed at the flue gas produced by a certain 500MW coal-fired power plant (with air excess control, flow rate 145×10 4 N m 3 / h, carbon dioxide content 14.6vol%, temperature 200°C), using the carbon dioxide capture liquefaction process of the present invention, cascade use of flue gas waste heat, part of the flue gas is subjected to carbon dioxide separation treatment, and liquid crude carbon dioxide is produced. The technological process that this embodiment adopts sees figure 1 , whose details are described in Example 1.

[0036] In this implementation case, using the process of the present invention, the regeneration tower 7 does not require additional steam, and only by utilizing the waste heat (200→80°C) of all the flue gas of the coal-fired power plant, it can achieve 8.7% of the total flue gas Liquefaction with carbon dioxide...

Embodiment 3

[0040] Table 5 Average composition of flue gas in a 600MW natural gas power generation project

[0041]

[0042] This embodiment is aimed at the flue gas produced by a 600MW coal-fired power plant (with air excess control, flow rate 260×10 4 N m 3 / h, carbon dioxide content 8.0vol%, temperature 200°C), the carbon dioxide capture liquefaction process of the present invention is adopted, the waste heat of the flue gas is used in stages, and carbon dioxide is separated from part of the flue gas to produce liquid crude carbon dioxide. The technological process that this embodiment adopts sees figure 1 , whose details are described in Example 1.

[0043] In this implementation case, using the process of the present invention, the regeneration tower 7 does not need additional steam, and only by using the waste heat (200→80°C) of all the flue gas of the coal-fired power plant, it can achieve 17.3% of the total flue gas Liquefaction with carbon dioxide capture. The process simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com