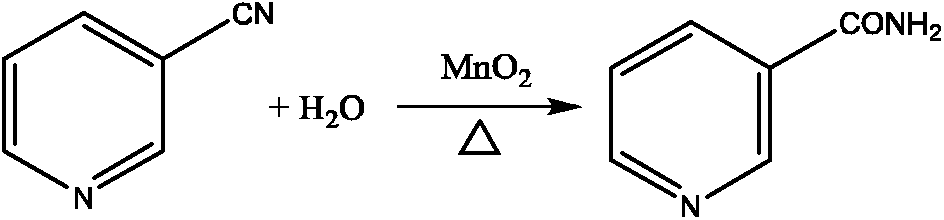

A kind of nicotinamide production method

A production method, the technology of nicotinamide, which is applied in the field of nicotinamide production, can solve problems such as the difficulty of solvent recycling, the increase of equipment production load, and the azeotropy of alcohol and water, so as to reduce the probability of agglomeration or agglomeration and reduce the emission rate , The effect of reducing the amount of waste liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

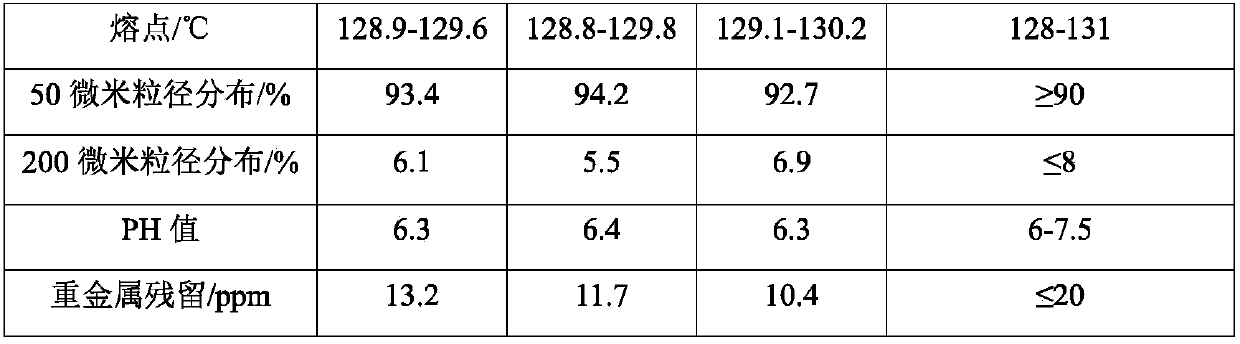

Embodiment 1

[0021] A production method of nicotinamide, which is prepared by using water, 3-cyanopyridine, and manganese dioxide in a weight ratio of 50:40:2, putting them into a reaction tank, controlling the temperature at 95°C, and stirring for 8 hours. Therefore, the stirring speed is to control the solution so that bumping does not occur.

Embodiment 2

[0023] A method for producing nicotinamide, which uses water, 3-cyanopyridine, and manganese dioxide in a weight ratio of 60:50:5, puts them into a reaction tank, controls the temperature at 95-110°C, and stirs the hydrolysis reaction After 10 hours, it is obtained through the steps of hot filtration, decolorization, concentration, filtration, recrystallization, refiltration, dissolution, granulation, and drying. During the stirring process, it is advisable to control the solution from bumping.

Embodiment 3

[0025] A method for producing nicotinamide, which uses water, 3-cyanopyridine, and manganese dioxide in a weight ratio of 55:45:3, puts them into a reaction tank, controls the temperature at 95-110°C, and stirs and hydrolyzes for 9 hours , and then obtained through the steps of hot filtration, decolorization, concentration, filtration, recrystallization, refiltration, dissolution, granulation, and drying. During the stirring process, it is advisable to control the solution from bumping. The hot filtration is to filter it immediately after the hydrolysis reaction is completed, and adopt two suction filtration treatments, and return the solid to the hydrolysis step; the decolorization is to pass the filtrate after the hot filtration through the decolorization treatment in the activated carbon decolorizer ; The concentration is to distill 20 parts by weight of water from the decolorized material, and then it is cooled and crystallized until the amount of crystals no longer increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com