Flame retardant catalyst of metal organic frame complex and preparation method thereof

A technology of metal-organic frameworks and complexes, applied in the field of flame-retardant synergists in flame-retardant materials science, to achieve the effects of easy industrialization, good migration resistance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

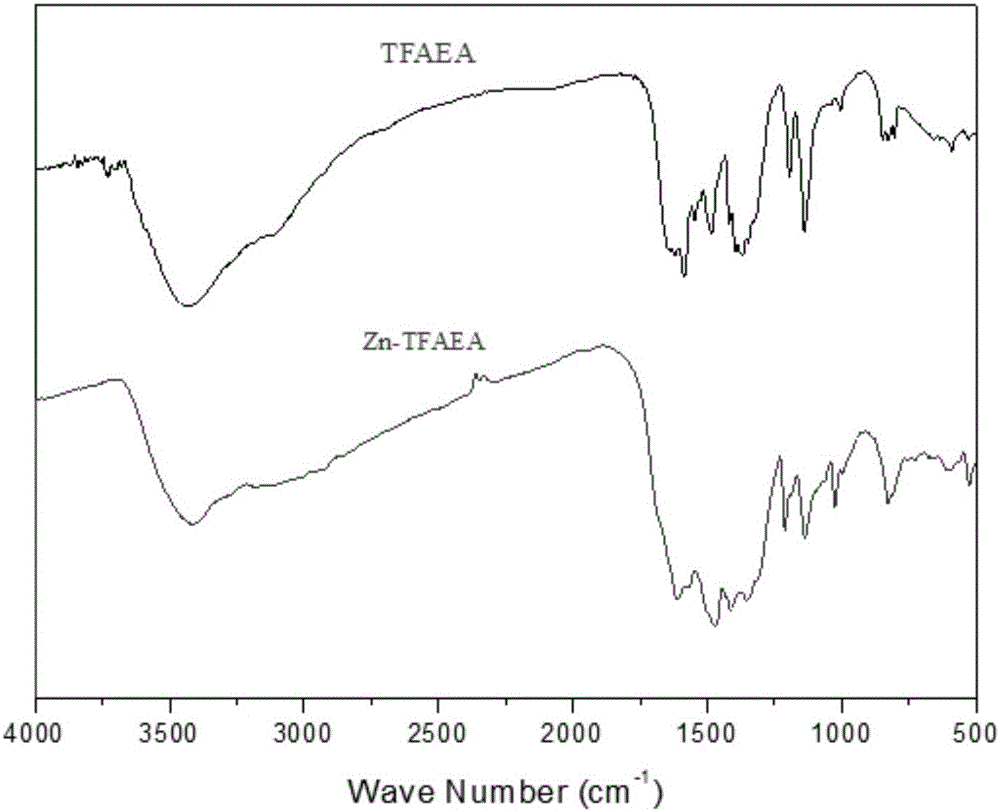

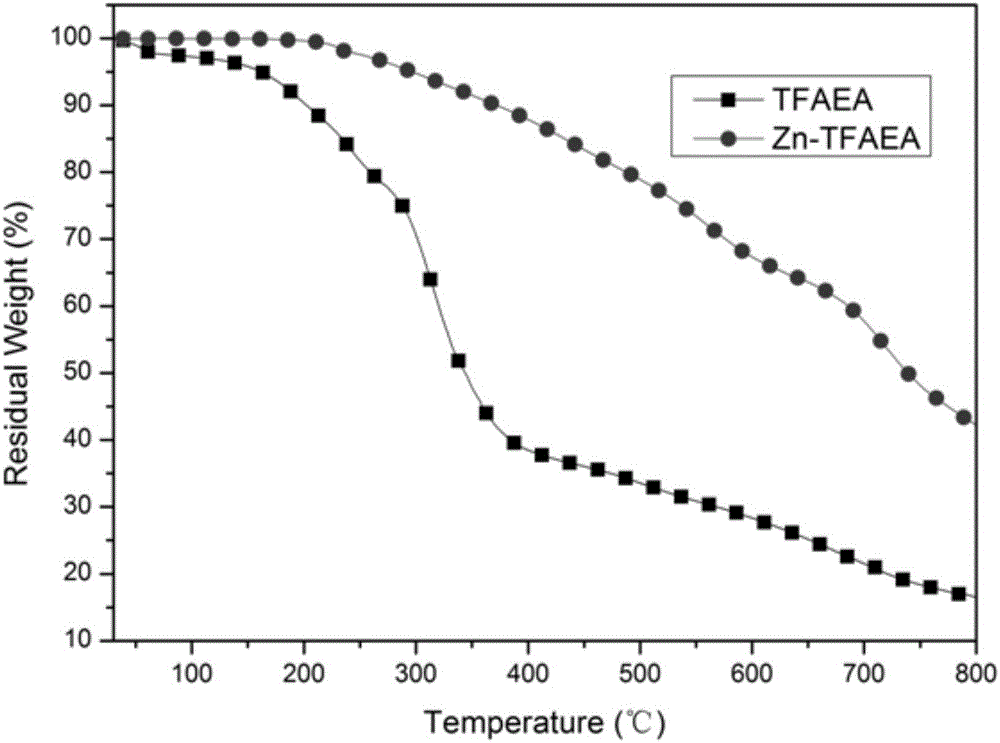

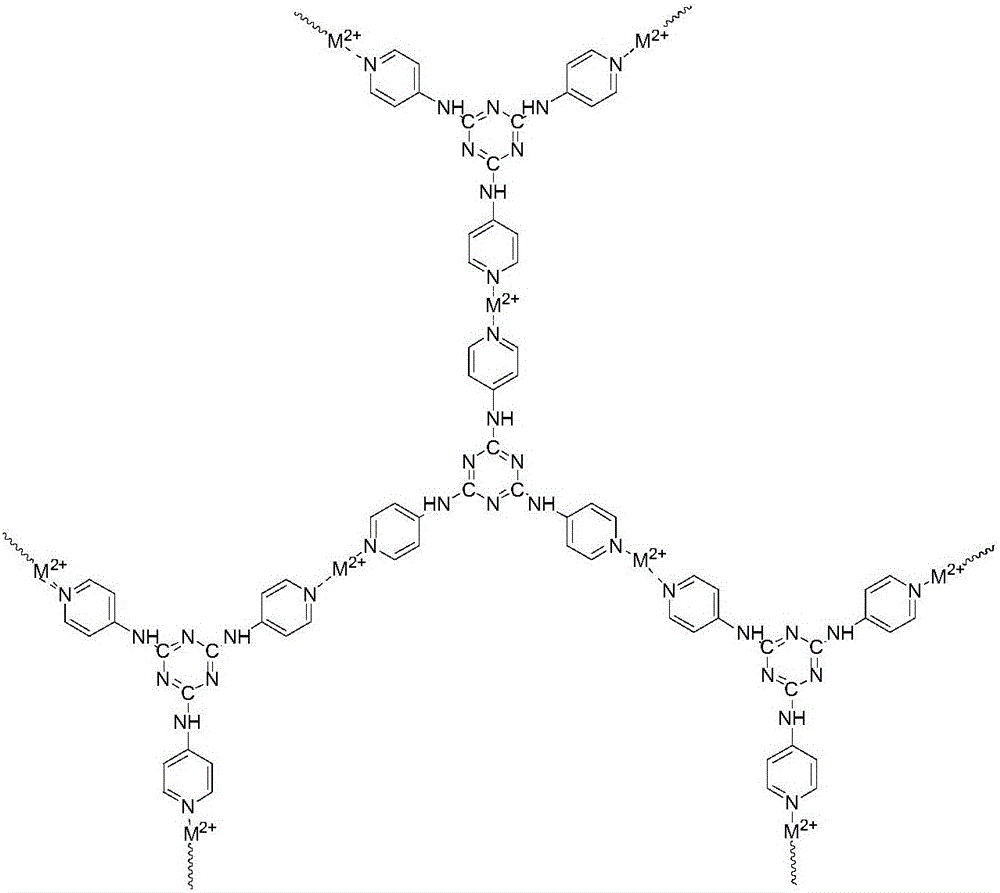

[0025] Fully dissolve 0.1mol cyanuric chloride in 150ml acetonitrile, add 0.3mol sodium carbonate and stir evenly; then add dropwise 70ml of acetonitrile solution containing 0.42mol 4-aminopyridine, heat up to reflux, react for 12 hours, and cool the solution to room temperature, filtered, washed three times with tetrahydrofuran, and vacuum-dried at 80°C for 24 hours to obtain the ligand 1,3,5-tris(4-aminopyridine)triazine (TFAEA) with a yield of 89%. in N 2 Under protection, add 0.1mol 1,3,5-tris(4-aminopyridine)triazine, 0.25mol zinc acetate, and 300ml ethanol into a 500ml three-neck flask, stir fully, and after completely dissolving, heat up to reflux, react After 16 hours, the solution was slowly cooled to room temperature, filtered, washed twice with ethanol and once with distilled water, and vacuum-dried at 80°C for 24 hours to obtain the target product organometallic complex flame retardant catalyst Zn-TFAEA with a yield of 87%. (The infrared spectrograms of TFAEA and ...

Embodiment 2

[0027] Fully dissolve 0.1mol cyanuric chloride in 150ml acetonitrile, add 0.45mol sodium hydroxide and stir evenly; then dropwise add 70ml of acetonitrile solution containing 0.44mol 4-aminopyridine, heat up to reflux, react for 17h, and dissolve the solution Cool to room temperature, filter, wash with tetrahydrofuran three times, and vacuum-dry at 80°C for 24 hours to obtain the ligand 1,3,5-tris(4-aminopyridine)triazine (TFAEA) with a yield of 90%. in N 2 Under protection, add 0.1mol 1,3,5-tris(4-aminopyridine)triazine, 0.35mol palladium acetate, and 300ml ethanol into a 500ml three-necked flask, stir thoroughly, and after completely dissolving, heat up to reflux, react After 24 hours, the solution was slowly cooled to room temperature, filtered, washed twice with ethanol and once with distilled water, and vacuum-dried at 80°C for 24 hours to obtain the target product organometallic complex flame retardant catalyst Pd-TFAEA with a yield of 83%.

[0028] Example 2

[0029]A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com