Building fireproof material

A fireproof material and construction technology, applied in fireproof coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of short service life, insignificant fireproof effect, etc. Easy to decolorize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

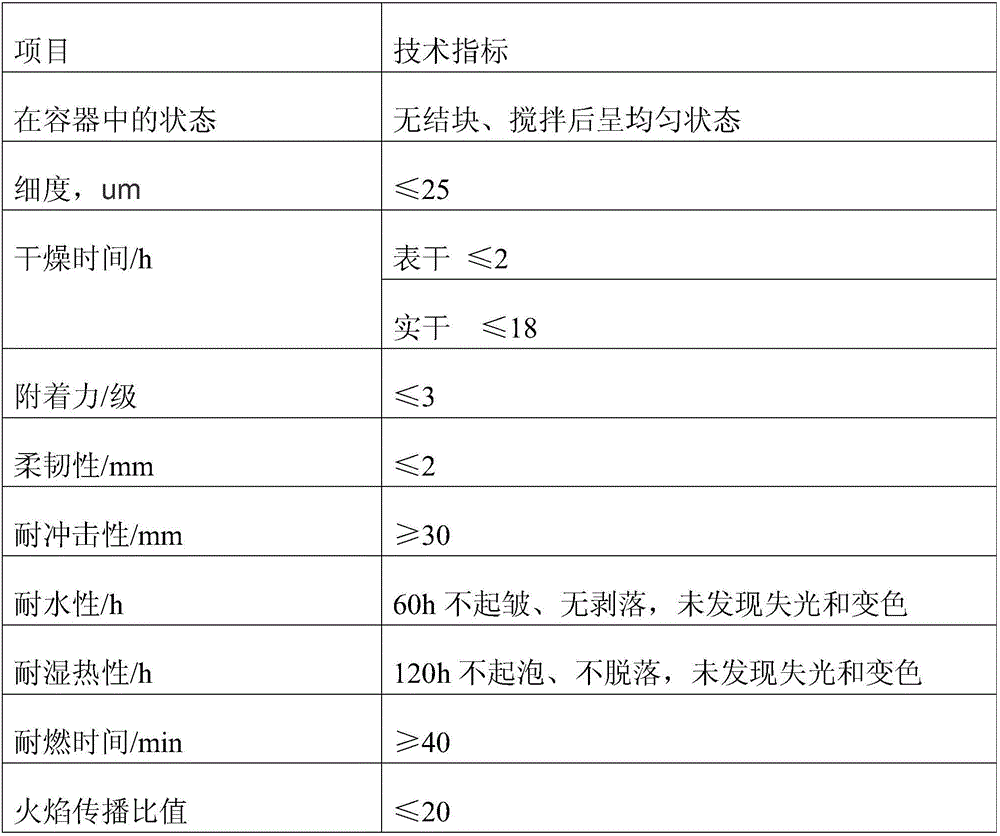

Embodiment 1

[0019] A kind of fireproof material for building, described fireproof material for building is fireproof paint, by weight, the raw material of preparation described fireproof paint comprises: composite base material resin 70 parts, pentaerythritol 18 parts, ammonium polyphosphate 18 parts, calcined 12 parts of kaolin powder, 8 parts of calcined vermiculite powder, 19 parts of hydroxypropyl methylcellulose ether, 6 parts of leveling agent, 11 parts of sodium fluorosilicate, 16 parts of uric acid, 22 parts of water glass, 18 parts of borax, aluminum sulfate 11 parts of potassium, 12 parts of copper sulfate, 21 parts of flame retardant and 11 parts of p-phenylenediamine.

[0020] The flame retardant is an inorganic flame retardant, and the inorganic flame retardant is graphite and magnesium hydroxide in a weight ratio of 2:1.

[0021] The composite base resin is acrylic resin, epoxy resin and polyurethane resin, and the weight ratio is 1:2:1.

[0022] The leveling agent is an ac...

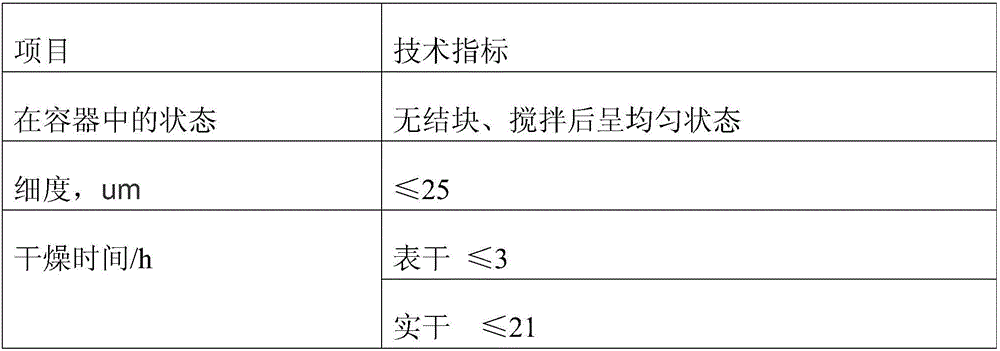

Embodiment 2

[0042] A kind of fireproof material for building, described fireproof material for building is fireproof paint, by weight, the raw material of preparation described fireproof paint comprises: composite base material resin 100 parts, pentaerythritol 28 parts, ammonium polyphosphate 13 parts, calcined 8 parts of kaolin powder, 12 parts of calcined vermiculite powder, 15 parts of hydroxypropyl methylcellulose ether, 5 parts of leveling agent, 20 parts of sodium fluorosilicate, 10 parts of uric acid, 37 parts of water glass, 13 parts of borax, aluminum sulfate 17 parts of potassium, 22 parts of copper sulfate, 24 parts of flame retardant and 5 parts of p-phenylenediamine.

[0043] The flame retardant is an organic flame retardant, the organic flame retardant is red phosphorus and phosphoric acid ester, and the weight ratio is 2:1.

[0044] The composite base resin is acrylic resin and epoxy resin, and the weight ratio is 3:1.

[0045] The leveling agent is an acrylic leveling age...

Embodiment 3

[0054]A kind of fireproof material for building, described fireproof material for building is fireproof paint, by weight, the raw material for preparing described fireproof paint comprises: 40 parts of composite base material resin, 12 parts of pentaerythritol, 25 parts of ammonium polyphosphate, calcined 18 parts of kaolin powder, 5 parts of calcined vermiculite powder, 30 parts of hydroxypropyl methylcellulose ether, 10 parts of leveling agent, 5 parts of sodium fluorosilicate, 28 parts of uric acid, 15 parts of water glass, 28 parts of borax, aluminum sulfate 8 parts of potassium, 4 parts of copper sulfate, 14 parts of flame retardant and 17 parts of p-phenylenediamine.

[0055] The flame retardant is an inorganic flame retardant, and the inorganic flame retardant is graphite and magnesium hydroxide in a weight ratio of 2:1.

[0056] The composite base resin is acrylic resin, epoxy resin and polyurethane resin, and the weight ratio is 1:2:1.

[0057] The leveling agent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com