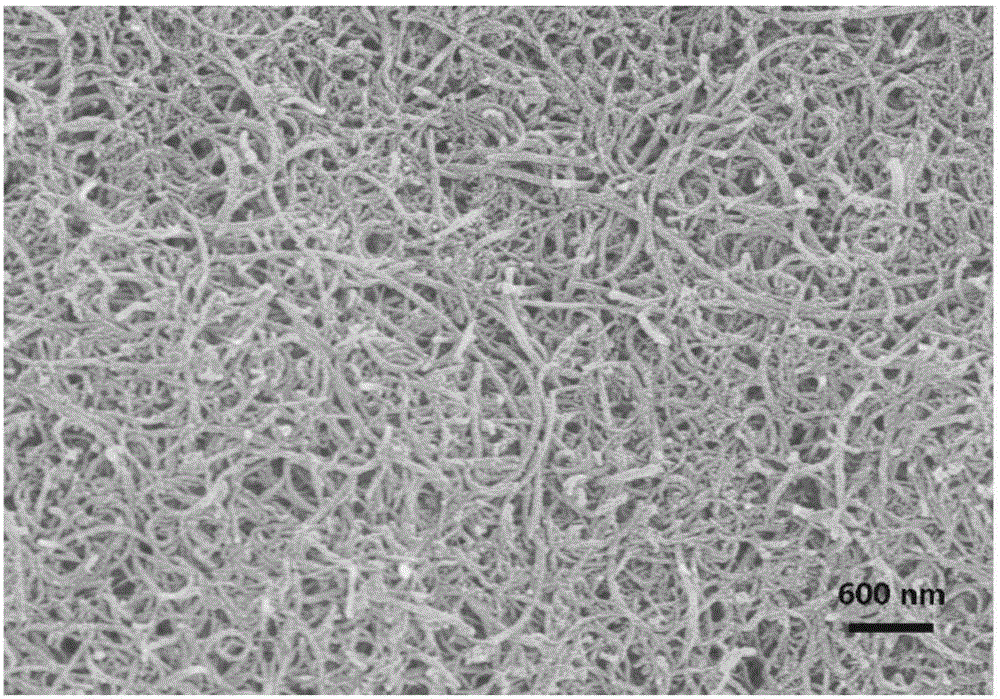

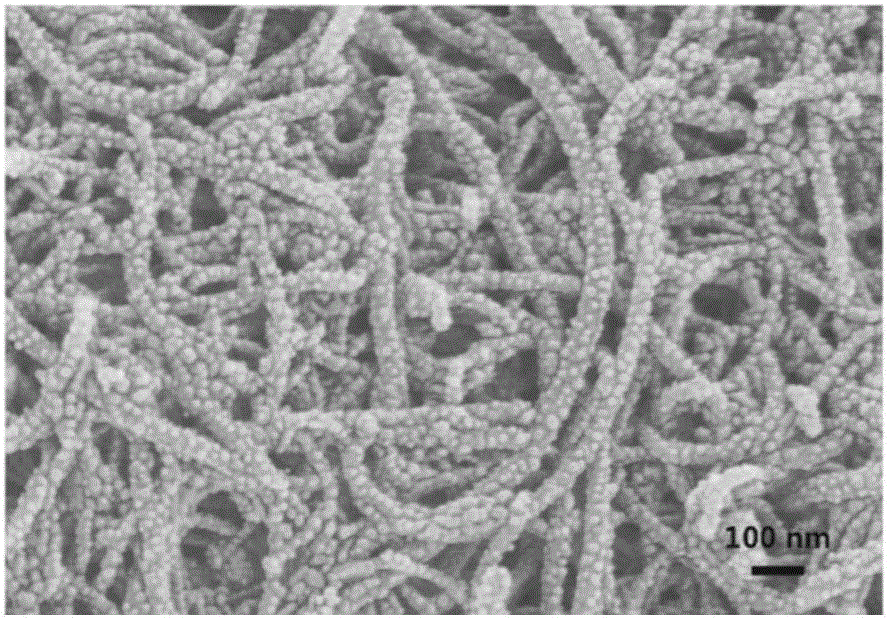

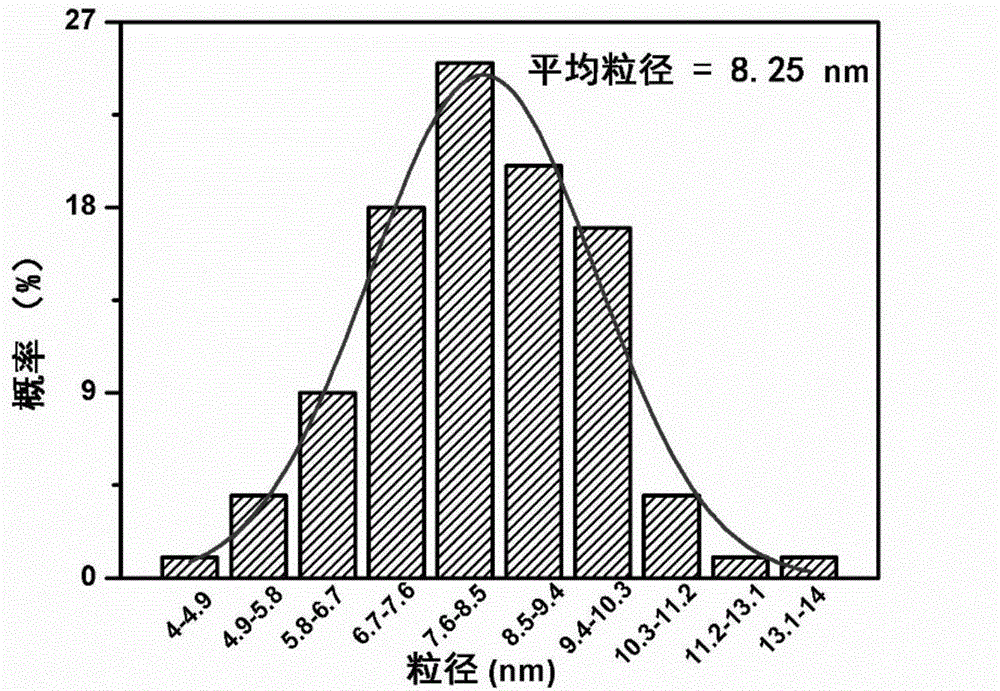

Method for uniformly cladding carbon nanotubes by nano ferroferric oxide magnetic particles

A technology of ferroferric oxide and magnetic particles, which is applied in the field of nanocomposite material preparation, can solve problems such as uncontrollable and non-uniform carbon nanotubes, and achieve the effects of controllable structure, improved electromagnetic absorption efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Put 20 mL of triethylene glycol in a dry and clean 100 mL beaker, add 1 g of multi-walled carbon nanotubes (with an inner diameter of 30-50 nm and a length of 10-20 μm), and stir to obtain a carbon nanotube dispersion solution;

[0036] 2) Take 0.1 g of iron acetylacetonate, add it to the above-mentioned dispersion solution, and perform cell crushing and ultrasonication for 5 minutes to obtain a mixed solution containing iron salt and carbon nanotubes;

[0037] 3) Sodium hydroxide is configured into a 6mol / L aqueous solution;

[0038] 4) Take another dry and clean 50mL beaker, add 10mL of triethylene glycol, add 1mL of the above-mentioned sodium hydroxide solution, and stir evenly to obtain an alkali-alcohol solution;

[0039] 5) Add the alkali-alcohol solution to the mixed solution containing iron salt and carbon nanotubes, and then perform cell crushing and ultrasonication for 5 minutes;

[0040] 6) Move the solution obtained in step 5) to a reaction kettle, put i...

Embodiment 2

[0046] 1) Put 20 mL of triethylene glycol in a dry and clean 100 mL beaker, add 1 g of multi-walled carbon nanotubes (with an inner diameter of 30-50 nm and a length of 10-20 μm), and stir to obtain a carbon nanotube dispersion solution;

[0047] 2) Take 0.5 g of ferrous acetylacetonate, add it to the above dispersion solution, and perform cell crushing and ultrasonication for 5 minutes to obtain a mixed solution containing iron salt and carbon nanotubes;

[0048] 3) Sodium hydroxide is configured into a 6mol / L aqueous solution;

[0049] 4) Take another dry and clean 50mL beaker, add 10mL of ethylene glycol, add 4mL of the above-mentioned sodium hydroxide solution, and stir evenly to obtain an alkali-alcohol solution;

[0050] 5) Add the alkali-alcohol solution to the mixed solution containing iron salt and carbon nanotubes, and then perform cell crushing and ultrasonication for 5 minutes;

[0051] 6) Move the solution obtained in step 5) to a reaction kettle, put it in an ov...

Embodiment 3

[0055] 1) Put 20 mL of diethylene glycol in a dry and clean 100 mL beaker, add 1 g of multi-walled carbon nanotubes (with an inner diameter of 30-50 nm and a length of 10-20 μm), and stir to obtain a carbon nanotube dispersion solution;

[0056] 2) Take 0.1 g of iron acetylacetonate, add it to the above-mentioned dispersion solution, and perform cell crushing and ultrasonication for 5 minutes to obtain a mixed solution containing iron salt and carbon nanotubes;

[0057] 3) Sodium hydroxide is configured into a 6mol / L aqueous solution;

[0058] 4) Take another dry and clean 50mL beaker, add 10mL of diethylene glycol, add 1-4mL of the above sodium hydroxide solution, and stir evenly to obtain an alkali-alcohol solution;

[0059] 5) Add the alkali-alcohol solution to the mixed solution containing iron salt and carbon nanotubes, and then perform cell crushing and ultrasonication for 5 minutes;

[0060] 6) Move the solution obtained in step 5) to a reaction kettle, put it in an ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com