Method using water-retaining agent containing protein to perform original soil greening on slight saline-alkali soil

A water-retaining agent and protein technology, applied in chemical instruments and methods, botanical equipment and methods, applications, etc., can solve the problems of poor water-holding capacity of NaCl solution, poor water-absorbing capacity and poor water-holding capacity of NaCl solution, and achieve good water-holding effect. , Good water retention capacity, and the effect of improving water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

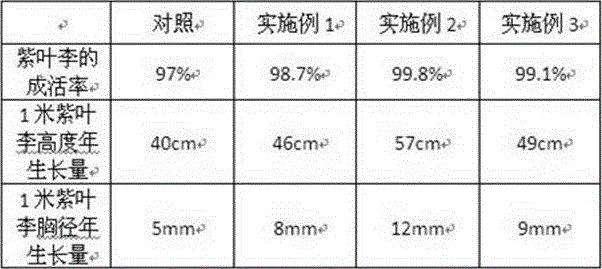

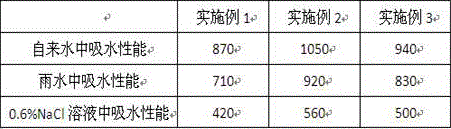

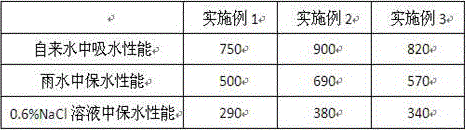

Embodiment 1

[0039] Example 1 A protein-containing water-retaining agent

[0040] Described water retaining agent, the mass ratio of each raw material component is:

[0041] 15 parts of soybean meal powder, 20 parts of cottonseed meal powder, 370 parts of acrylic acid, 1.2 parts of willow leaf powder, 2.5 parts of cypress leaf powder, 1.2 parts of peanut seedling powder, 2.5 parts of grass straw powder, 0.007 parts of cellulose degrading bacteria, 0.7 parts of urea , 2.5 parts of potassium dihydrogen phosphate, 1.2 parts of seaweed powder, 0.7 parts of sorghum starch, 1.2 parts of cowpea starch, 1.2 parts of fermented mink manure, 1.2 parts of fermented duck manure, 1.2 parts of medical stone powder, 1.2 parts of bentonite, 1.2 parts of indole acetic acid , 0.2 parts of crosslinking agent, 3 parts of initiator, 350 parts of water.

[0042] The mesh numbers of the soybean meal powder and cottonseed meal powder are 80-270 mesh;

[0043] The active ingredient of the acrylic acid is 99%;

...

Embodiment 2

[0057] Embodiment 2 A kind of water-retaining agent containing protein

[0058] Described water retaining agent, the mass ratio of each raw material component is:

[0059] 20 parts of soybean meal powder, 30 parts of cottonseed meal powder, 510 parts of acrylic acid, 2 parts of willow leaf powder, 3 parts of cypress leaf powder, 2 parts of peanut seedling powder, 3 parts of grass straw powder, 0.01 part of cellulose degrading bacteria, 1 part of urea , 3 parts of potassium dihydrogen phosphate, 2 parts of seaweed powder, 1 part of sorghum starch, 2 parts of cowpea starch, 2 parts of fermented mink manure, 2 parts of fermented duck manure, 2 parts of medical stone powder, 2 parts of bentonite, 2 parts of indole acetic acid , 0.3 parts of crosslinking agent, 4.5 parts of initiator, and 500 parts of water.

[0060] The mesh numbers of the soybean meal powder and cottonseed meal powder are 80-270 mesh;

[0061] The active ingredient of the acrylic acid is 99%;

[0062] The mesh...

Embodiment 3

[0075] Embodiment 3 uses protein-containing water retaining agent

[0076] Described water retaining agent, the mass ratio of each raw material component is:

[0077] 30 parts of soybean meal powder, 50 parts of cottonseed meal powder, 770 parts of acrylic acid, 3.5 parts of willow leaf powder, 5 parts of cypress leaf powder, 3.5 parts of peanut seedling powder, 5 parts of grass straw powder, 0.018 parts of cellulose degrading bacteria, 2 parts of urea , 5 parts of potassium dihydrogen phosphate, 3.5 parts of seaweed powder, 2 parts of sorghum starch, 3.5 parts of cowpea starch, 3.5 parts of fermented mink manure, 3.5 parts of fermented duck manure, 3.5 parts of medical stone powder, 3.5 parts of bentonite, 3.5 parts of indole acetic acid , 0.5 parts of crosslinking agent, 7 parts of initiator, and 750 parts of water.

[0078] The mesh numbers of the soybean meal powder and cottonseed meal powder are 80-270 mesh;

[0079] The active ingredient of the acrylic acid is 99%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com