Method for directly writing graphene pattern on nonmetal surface by laser

A non-metallic surface, graphene technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of inability to synchronize graphene preparation and patterning, poor graphene performance, etc., to achieve easy operation, The effect of simple operation and safe preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

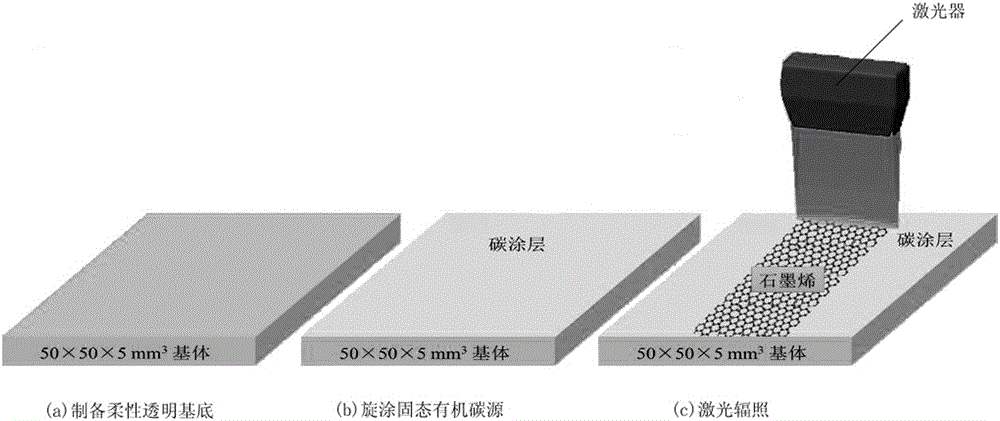

[0026] figure 1 It is a schematic diagram of the preparation process of an embodiment of the present invention. refer to figure 1 , the laser of the present invention directly writes the graphene pattern method on non-metallic surface and comprises the steps:

[0027] Step 1, preparing a polydimethylsiloxane base;

[0028] Step 2. Spin coating the solid organic carbon source: use a spin coater to evenly spin coat the solid organic carbon source on the surface of the flexible transparent substrate described in step 1 at a set speed and spin coating time to obtain a uniform carbon coating;

[0029] Step 3. Laser irradiation: under the protection of an inert gas, use an ultrashort pulse laser beam to move the surface of the carbon coating obtained in step 2 according to the designed pattern, and irradiate the carbon coating. The organic carbon source of the carbon coating is in the laser Under the irradiation of light, the long carbon chain is cracked into short carbon chain, ...

Embodiment 1

[0034] In this embodiment, a femtosecond laser is used to directly write graphene patterns on polydimethylsiloxane (PDMS). Specific steps are as follows:

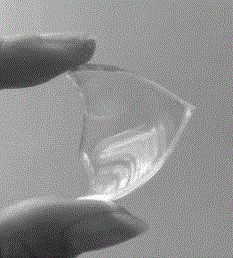

[0035] Step 1. Preparation of PDMS substrate

[0036] First, mix dimethyl vinyl polysiloxane and silane coupling agent in a ratio of 10:1, stir the mixed solution thoroughly to generate bubbles, then put the mixed solution in an ultrasonic cleaning instrument for 10 minutes, After the air bubbles completely disappeared, pour the mixed solution into a mold with a size of 5cm×5cm×5cm. Finally, put the mold containing the mixed solution in an oven at 80°C for 7 hours to solidify the mixed solution to obtain Flexible transparent PDMS substrates, such as figure 2 shown.

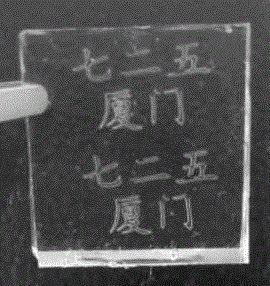

[0037] Step 2, coating carbon source sucrose on the PDMS substrate prepared in step 1

[0038] Grind the sucrose particles to a particle size of 20 μm and mix them with alcohol at a ratio of 10g:16ml to form a suspension. Use a spin coater to coat the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com