Novel negative electrode material of sodium-ion battery as well as preparation method and application thereof

A sodium ion battery and negative electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of poor cycle performance and low capacity, and achieve low cost and high reversible capacity , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

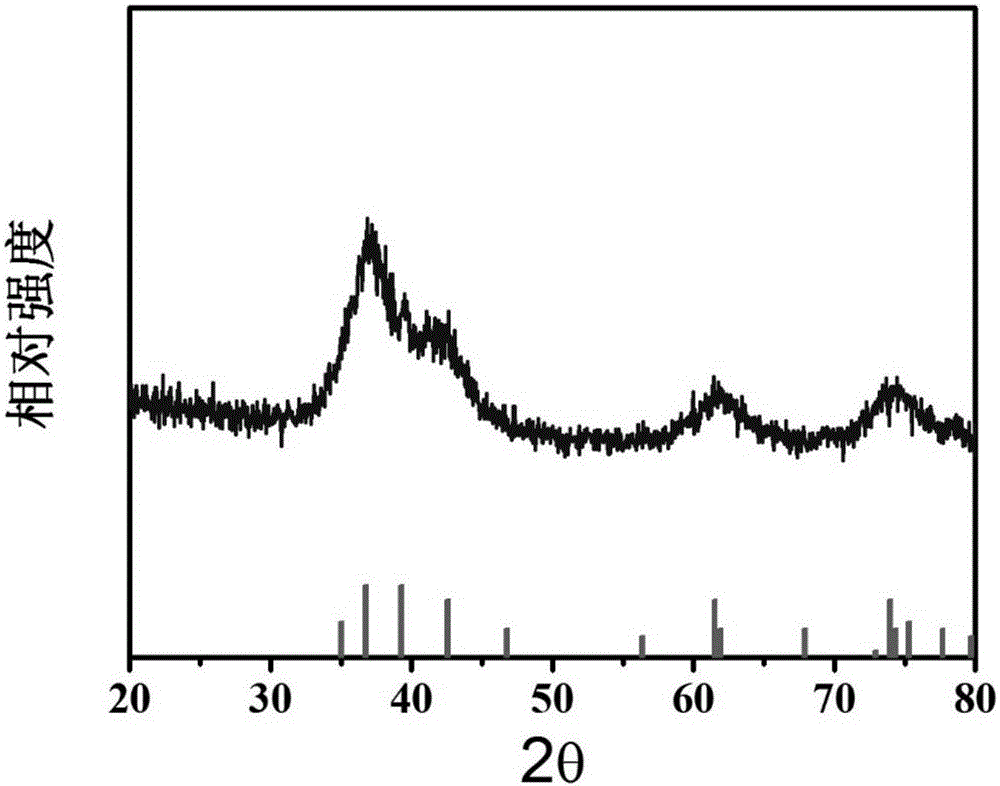

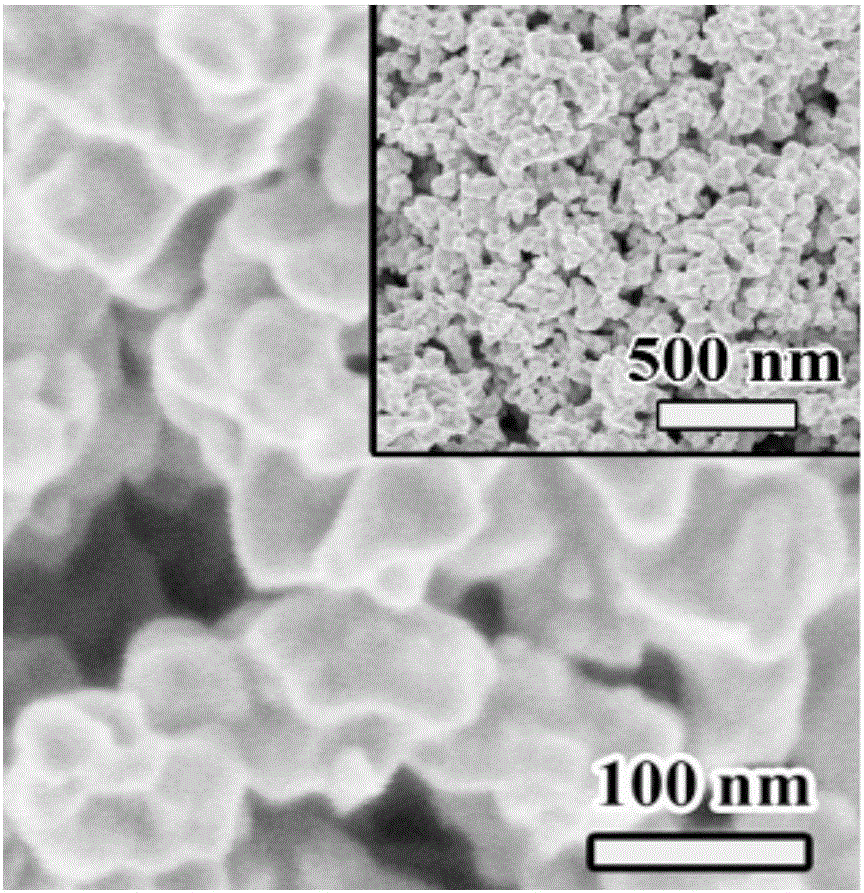

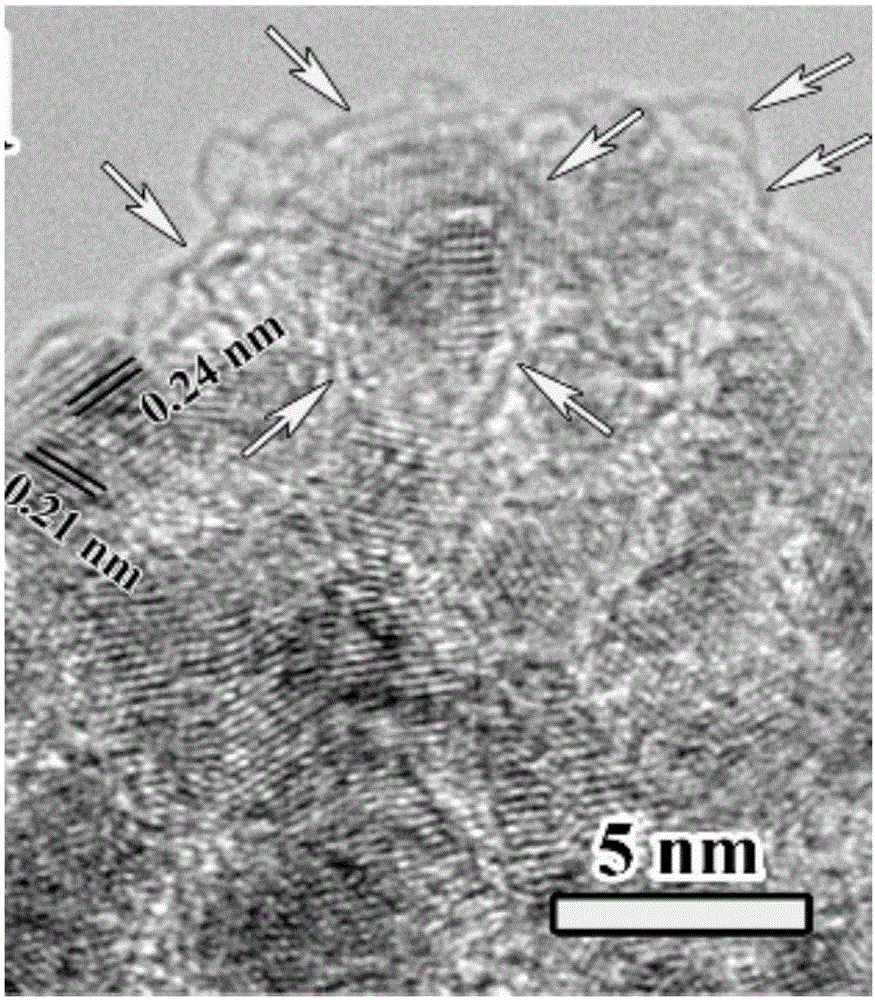

[0056] A composite of molybdenum carbide nanoparticles and ultrathin graphene shell (MoC@GS) anode material was synthesized by a two-step method. First prepare the precursor Mo 3 (BTC) 2 , and then the precursor product was in-situ carbonized in a quartz tube under an argon atmosphere to obtain the composite of molybdenum carbide nanoparticles and ultrathin graphene shells (MoC@GS), with a diameter of 1~ 10nm.

[0057] The specific operation is as follows:

[0058] Dissolve molybdenum hexacarbonyl and trimesic acid at a molar ratio of 1:13.6 in dimethyl fumarate, reflux reaction at 155°C under an argon atmosphere for more than 5 days, filter, wash and dry to obtain the precursor Mo 3 (BTC) 2 , and then placed the precursor in a quartz tube under an argon atmosphere for in-situ carbonization at 700-900°C for 5 hours, cooled to room temperature, washed with dimethyl fumarate, and dried to obtain molybdenum monocarbide nanoparticles and ultra-thin graphite ene-shell composi...

Embodiment 2

[0060] A composite of molybdenum carbide nanoparticles and ultrathin graphene shell (MoC@GS) anode material was synthesized by a two-step method. First prepare the precursor Mo 3 (BTC) 2 , and then the precursor product was in-situ carbonized in a quartz tube under an argon atmosphere to obtain the composite of molybdenum carbide nanoparticles and ultrathin graphene shells (MoC@GS), with a diameter of 1~ 10nm.

[0061] The specific operation is as follows:

[0062] Dissolve molybdenum hexacarbonyl and trimesic acid at a molar ratio of 1:10 in dimethyl fumarate, reflux reaction at 100°C under an argon atmosphere for more than 5 days, filter, wash and dry to obtain the precursor Mo 3 (BTC) 2 , and then place the precursor in a quartz tube under an argon atmosphere for in-situ carbonization at 500-1000°C for 2 hours, cool to room temperature, wash with dimethyl fumarate, and dry to obtain molybdenum monocarbide nanoparticles and ultra-thin graphite ene-shell composites (MoC...

Embodiment 3

[0064] A composite of molybdenum carbide nanoparticles and ultrathin graphene shell (MoC@GS) anode material was synthesized by a two-step method. First prepare the precursor Mo 3 (BTC) 2 , and then the precursor product was in-situ carbonized in a quartz tube under an argon atmosphere to obtain the composite of molybdenum carbide nanoparticles and ultrathin graphene shells (MoC@GS), with a diameter of 1~ 10nm.

[0065] The specific operation is as follows:

[0066] Dissolve molybdenum hexacarbonyl and trimesic acid at a molar ratio of 1:15 in dimethyl fumarate, reflux reaction at 200°C for more than 3 days under an argon atmosphere, filter, wash, and dry to obtain a precursor Mo 3 (BTC) 2 , and then placed the precursor in a quartz tube under an argon atmosphere for in-situ carbonization at 500-1000°C for 8 hours, cooled to room temperature, washed with dimethyl fumarate, and dried to obtain molybdenum monocarbide nanoparticles and ultra-thin graphite ene-shell composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com