Preparation method of sound-insulation aerated concrete building block prepared from dyeing sludge

A technology for aerated concrete and printing and dyeing sludge, applied in the field of building materials, can solve the problems of poor geotechnical strength, easy corruption, large capacity, etc., and achieve the effects of improving strength and toughness, reducing pollution, and improving toughness and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

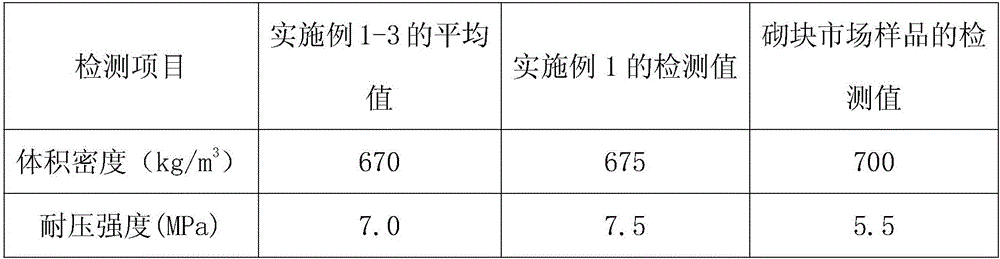

Examples

Embodiment 1

[0026] A method for preparing soundproof aerated concrete blocks from printing and dyeing sludge, comprising the following steps:

[0027] Step 1: Add the printing and dyeing sludge into lime water and soak for 12 hours, press filter until the water content is 22%, add the crushed polyester scraps, stir evenly, and dry at 38°C until the water content is 10%;

[0028] Step 2: Mix and grind river sand, lime, gypsum, expanded vermiculite powder and dried printing and dyeing sludge, pass through a 120-mesh sieve, take the under-sieve, and heat with steam;

[0029] Step 3: Add aluminum powder, stir, and steam to obtain aerated concrete mixture slurry;

[0030] Step 4: pour the air-entrained concrete mixture into shape, perform gas generation, static stop, cutting, and steam curing to obtain aerated concrete blocks. The temperature of the steam curing is 48°C, the pressure is 1.1MPa, and gas generation Stop for 3.5h.

[0031] In the solid content of the printing and dyeing sludge ...

Embodiment 2

[0042] A method for preparing soundproof aerated concrete blocks from printing and dyeing sludge, comprising the following steps:

[0043] Step 1: add printing and dyeing sludge to lime water and soak for 10 hours, press filter until the water content is 20%, add crushed polyester scraps, stir evenly, and dry at 35°C until the water content is 12%;

[0044] Step 2: Mix and grind river sand, lime, gypsum, expanded vermiculite powder and dried printing and dyeing sludge, pass through a 120-mesh sieve, take the under-sieve, and heat with steam;

[0045] Step 3: Add aluminum powder, stir, and steam to obtain aerated concrete mixture slurry;

[0046] Step 4: pour the air-entrained concrete mixture into shape, perform gas generation, static stop, cutting, and steam curing to obtain aerated concrete blocks. The temperature of the steam curing is 50°C, the pressure is 1.2MPa, and gas Stop for 4 hours.

[0047] In the solid content of the printing and dyeing sludge in the step 1, the...

Embodiment 3

[0058] A method for preparing soundproof aerated concrete blocks from printing and dyeing sludge, comprising the following steps:

[0059] Step 1: Add the printing and dyeing sludge into lime water and soak for 15 hours, press filter until the water content is 25%, add the crushed polyester scraps, stir evenly, and dry at 40°C until the water content is 8%;

[0060] Step 2: Mix and grind river sand, lime, gypsum, expanded vermiculite powder and dried printing and dyeing sludge, pass through a 120-mesh sieve, take the under-sieve, and heat with steam;

[0061] Step 3: Add aluminum powder, stir, and steam to obtain aerated concrete mixture slurry;

[0062] Step 4: pour the air-entrained concrete mixture slurry into shape, perform gas generation, static stop, cutting, and steam curing to obtain aerated concrete blocks. The temperature of the steam curing is 45°C, the pressure is 1.0MPa, and gas generation Stop for 3h.

[0063] In the solid content of the printing and dyeing slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com