Method for extraction and separation of verbascoside from rehmannia glutinosa

A technology of verbascoside and Rehmannia glutinosa, applied in chemical instruments and methods, sugar derivatives, sugar derivatives and other directions, can solve the problems of large solvent consumption and long time consumption, and achieve the effects of saving resources, high speed and controllable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

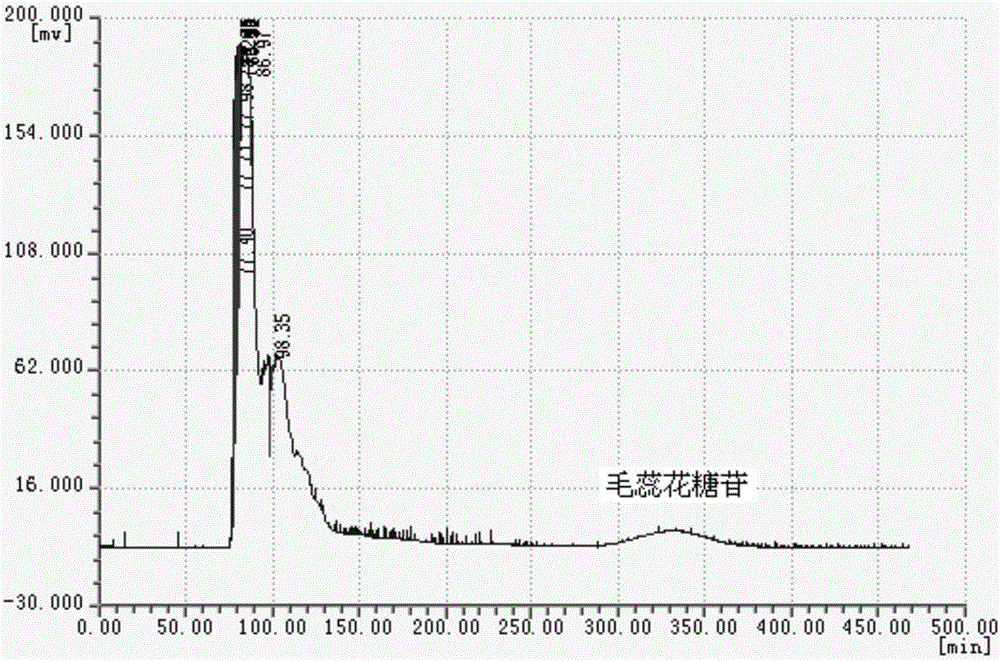

[0033] Extraction: Weigh 300g of rehmannia medicinal material, put it in a 1000ml round bottom flask, add 500ml of ethanol solution with a volume fraction of 75%, heat and reflux for extraction, the number of extractions is 2 times, and each time is 1.5h. Combine the extracts, cool, filter, move the filtrate to a 1000ml flask, spin dry with a rotary evaporator to obtain an extract. Enrichment of verbascoside with macroporous resin: Take a certain amount of pretreated D101 macroporous resin, pack it into a column, take the extract and dilute it with water and load it as a sample, and control the flow rate at 4BV / h until the adsorption is complete. Then carry out gradient elution, first elution with water to remove sugars, and then sequentially elution with 5%, 10%, 20% volume concentration of ethanol aqueous solution, each gradient elution, when the effluent is colorless, you can replace the next one Gradient, collect the eluate eluted with 5% ethanol aqueous solution, and conc...

Embodiment 2

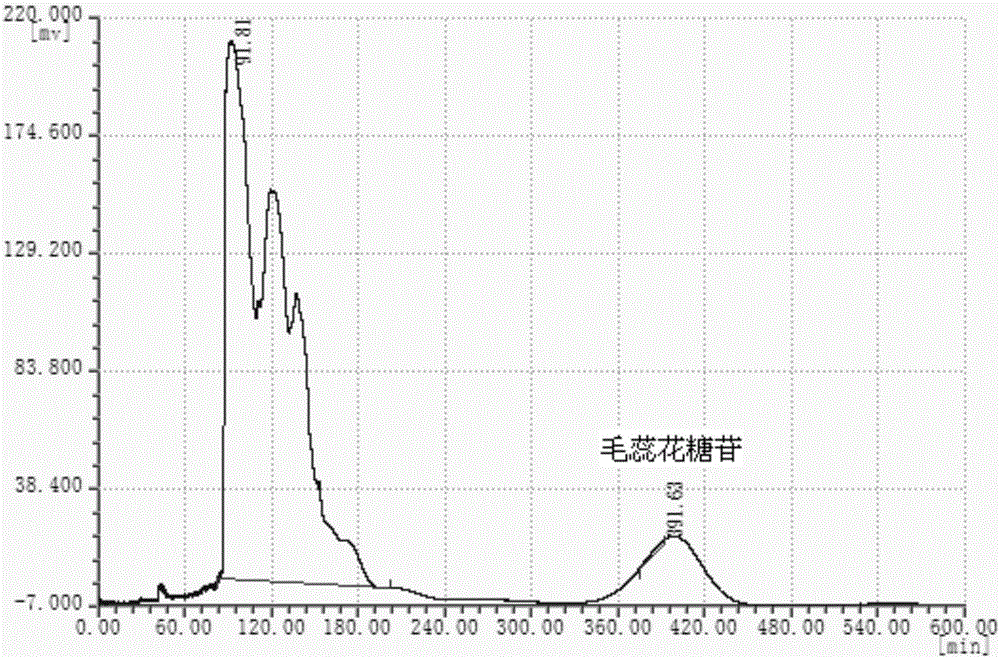

[0035]Extraction: Weigh 300g of rehmannia medicinal material, put it in a 1000ml round bottom flask, add 500ml of 75% ethanol solution, heat and reflux for extraction twice, each time is 1.5h. Combine the extracts, cool, filter, move the filtrate to a 1000ml flask, spin dry with a rotary evaporator to obtain an extract. Macroporous resin enrichment of verbascoside: take a certain amount of pretreated D101 resin (equivalent to 10g dry resin), pack it into a column, dilute the total extract of Rehmannia glutinosa with water as the loading solution, and control the flow rate of the resin column to 4BV / h until the adsorption is complete. Then carry out gradient elution, first elution with water to remove sugar components, and then sequentially elution with 10%, 20% volume concentration of ethanol aqueous solution, during each gradient elution, when the effluent is colorless, the next gradient can be replaced. The eluate eluted with 10% ethanol aqueous solution was collected and s...

Embodiment 3

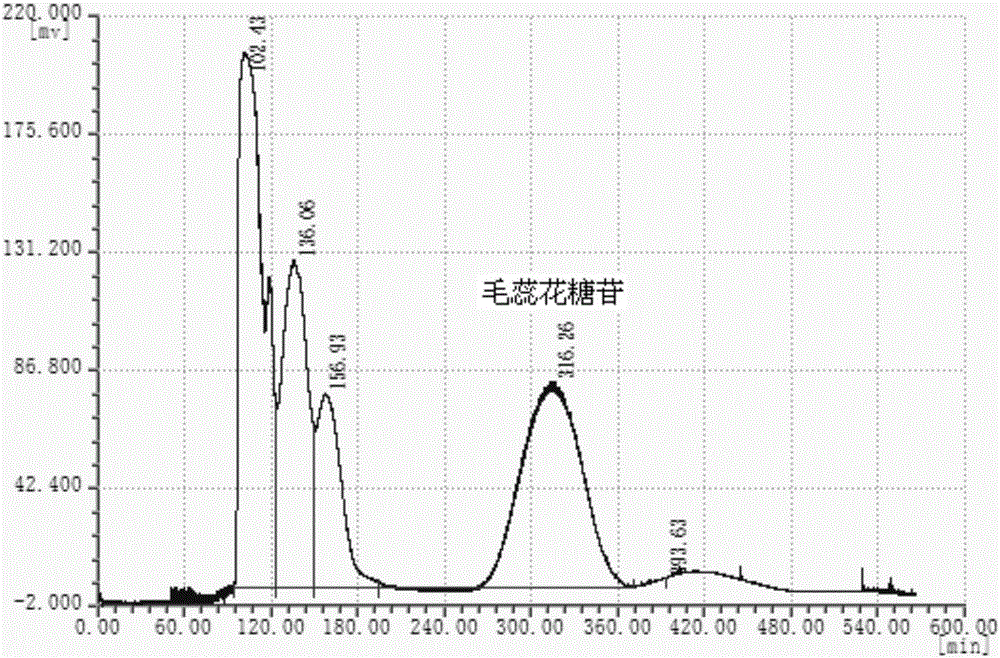

[0037] Extraction: Weigh 300g of rehmannia medicinal material, put it in a 1000ml round bottom flask, add 500ml of 75% ethanol solution, heat and reflux for extraction twice, each time is 1.5h. Combine the extracts, cool, filter, move the filtrate to a 1000ml flask, spin dry with a rotary evaporator to obtain an extract. Enrichment of verbascoside with macroporous resin: Take a certain amount of pretreated D101 resin (equivalent to 10g dry resin), pack it into a column, dilute the total extract of Rehmannia glutinosa and load the sample, control the flow rate of the resin column to 4BV / h until the adsorption completely. Then carry out gradient elution, first elution with water to remove sugar components, and then sequentially elution with 5%, 10%, 20% volume concentration of ethanol aqueous solution, during each gradient elution, the effluent can be replaced when it is colorless A gradient, collect the eluate eluting with 5% and 10% ethanol aqueous solution, combine, see the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com