Composite microorganism additive for removing mycotoxin and preparation method of composite microorganism additive

A technology of compound microorganisms and mycotoxins, applied in application, animal feed, animal feed, etc., can solve the problems of poor thermal stability of enzymes, reduced nutritional value and palatability of feed, difficult operation, etc., to achieve high stability and inhibit mold growth. and the production of mycotoxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

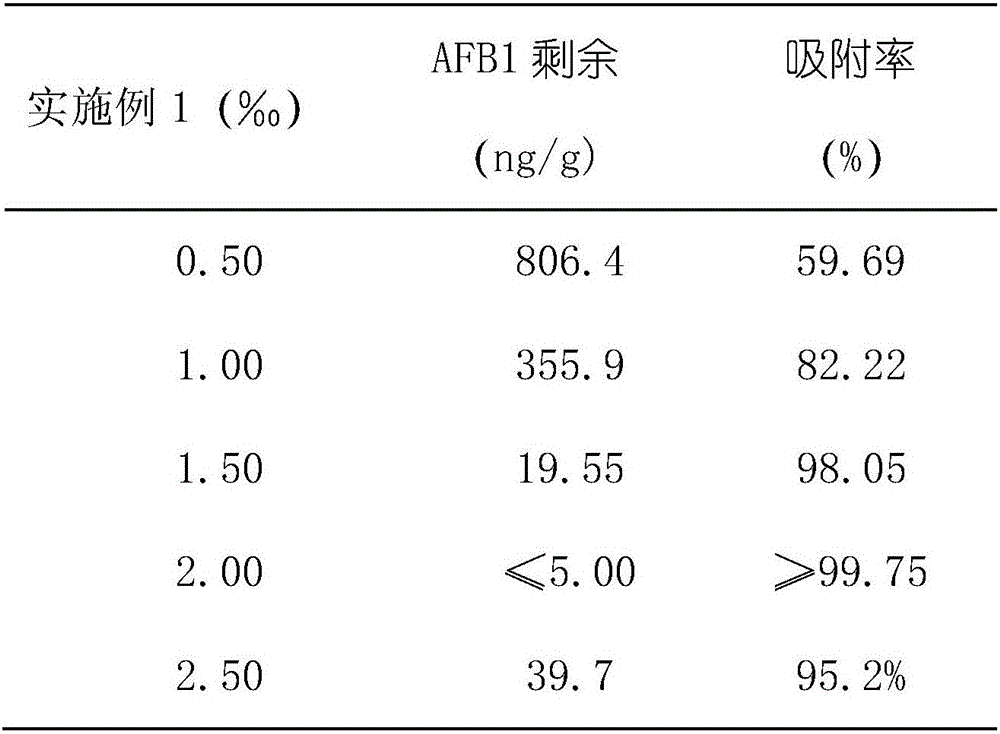

Embodiment 1

[0031] The compound microbial additive used to remove mycotoxins is made of the following raw materials: 1Kg of Lactobacillus plantarum, 1Kg of Bacillus subtilis, 1Kg of sodium propionate, 2Kg of ginger extract, 3Kg of proteolytic enzyme, 2Kg of gypsum, Mannan oligosaccharide 30Kg, montmorillonite 60Kg.

[0032] The preparation method of the above-mentioned composite microbial additive for removing mycotoxins adopts the following steps:

[0033] (1) According to the above weight, Lactobacillus plantarum and Bacillus subtilis with a bacterial count of ≥ 1 billion / g are selected for use; the Lactobacillus plantarum is purchased from Shandong Weilan Biotechnology Co., Ltd.; the Bacillus subtilis is purchased from Shandong Weilan Biological Technology Co., Ltd;

[0034] (2) preparation of ginger extract:

[0035] a. Wash the ginger, slice it and dry it naturally;

[0036] b. Place the air-dried ginger in step a in a drying oven at 55° C. for 8 hours, take it out and pulverize i...

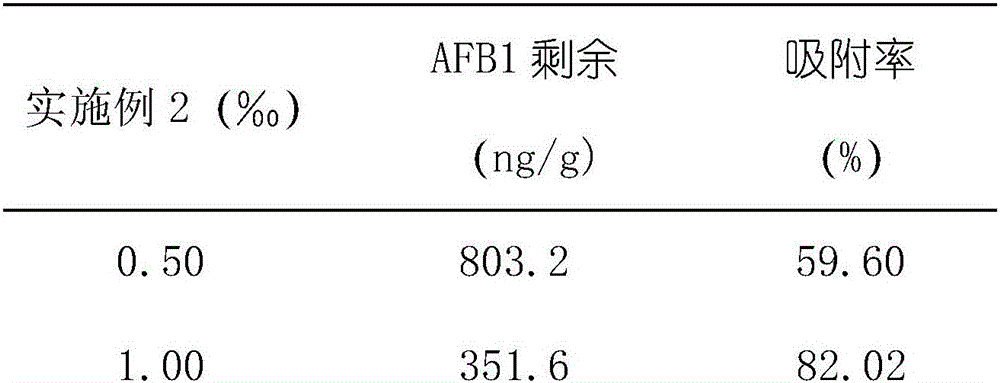

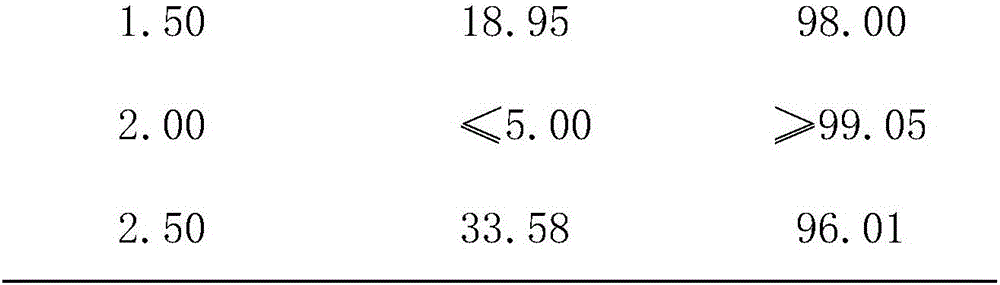

Embodiment 2

[0044] The compound microbial additive used to remove mycotoxins, its active ingredients are made of the following raw materials: 0.5Kg of Lactobacillus plantarum, 0.5Kg of Bacillus subtilis, 0.5Kg of sodium propionate, 1Kg of ginger extract, 2Kg of proteolytic enzyme, Gypsum 1Kg, mannan oligosaccharide 20Kg, montmorillonite 55Kg.

[0045] The preparation method of the above-mentioned composite microbial additive for removing mycotoxins adopts the following steps:

[0046] (1) According to the above-mentioned parts by weight, Lactobacillus plantarum and Bacillus subtilis with the number of bacteria ≥ 1 billion / g are selected for use; the Lactobacillus plantarum is purchased from Shandong Weilan Biotechnology Co., Ltd.; the Bacillus subtilis is purchased from Shandong Weilan Biotechnology Co., Ltd.;

[0047] (2) preparation of ginger extract:

[0048] a. Wash the ginger, slice it and dry it naturally;

[0049] b. Place the air-dried ginger in step a in a drying oven at 50° C...

Embodiment 3

[0057] The compound microbial additive used to remove mycotoxins is made of the following raw materials: 3Kg of Lactobacillus plantarum, 3Kg of Bacillus subtilis, 3Kg of sodium propionate, 3Kg of ginger extract, 4Kg of proteolytic enzyme, 3Kg of gypsum, Mannan oligosaccharide 40Kg, montmorillonite 75Kg.

[0058] The preparation method of the above-mentioned composite microbial additive for removing mycotoxins adopts the following steps:

[0059] (1) According to the above weight, Lactobacillus plantarum and Bacillus subtilis with a bacterial count of ≥ 1 billion / g are selected for use; the Lactobacillus plantarum is purchased from Shandong Weilan Biotechnology Co., Ltd.; the Bacillus subtilis is purchased from Shandong Weilan Biological Technology Co., Ltd;

[0060] (2) preparation of ginger extract:

[0061] a. Wash the ginger, slice it and dry it naturally;

[0062] b. Place the air-dried ginger in step a in a drying oven at 60° C. for 9 hours, take it out and pulverize i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com