Pyrus pyrifolia nakai enzyme and preparation method and application thereof

A technology of red pear enzyme and pear enzyme, applied in the field of red pear enzyme and its preparation, can solve the problem of unsatisfactory effect of boron element, etc., and achieve the effect of sweet and mellow taste, obvious efficacy and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

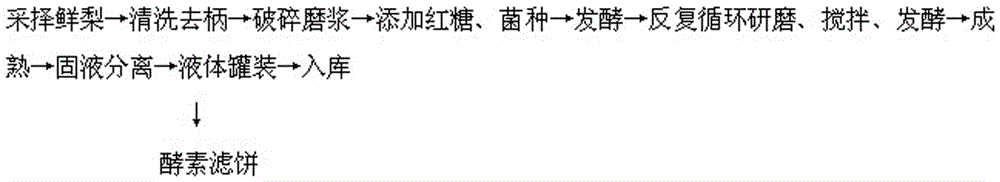

[0079] The preparation method of red pear enzyme of the present invention comprises pretreatment, fermentation step, specifically comprises:

[0080] A. Pretreatment: Sorting, removing handles, cleaning, crushing and refining the fresh organic red pears as raw materials;

[0081] B. Fermentation:

[0082] 1) Strain preparation: take intact fresh organic red pears, put them in rice bran and store them at room temperature for more than 15 days until the surface of the pear skin turns black and white enzyme spots appear; then the organic red pears are washed, crushed and refined, and added The weight ratio of sugar, sugar and organic red pear is 0.1~0.3:1, the measured sugar content is a, and transferred to fermenter for natural fermentation for more than 15 months to obtain the red pear enzyme strain, during which the sugar content of the fermentation liquid is monitored and Add sugar so that the sugar content is a, that is, keep the same as the sugar content when entering the ...

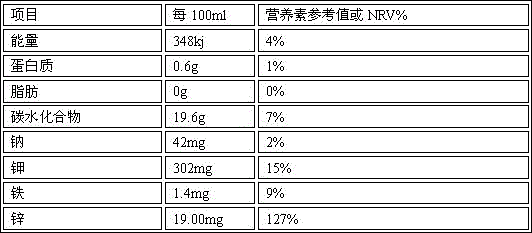

Embodiment 1

[0090] Take 3000kg of fresh red pears, sort them, remove the stalks, wash them, then crush them with a pulverizer, grind them with colloids, and then pump them into a closed 3.75m³ stainless steel fermentation tank, add 580Kg of brown sugar and 0.75kg of red pear enzyme bacteria species, and the sugar content of the fermentation broth was detected to be 18.1 degrees [°Brix]. The first six days are the first stage of fermentation, that is, the vaporization stage. Mechanical stirring is performed for 30 minutes every day, and then the pressure is 8kg / cm 2 Stir with compressed air for 30 minutes (the air pressure is 8kg / cm 2 Before entering the fermentation tank, it has undergone purification treatment such as pickling, alkali washing and air filter, the same below) continuously adding 590kg of organic brown sugar. That is the saccharification stage. Every three days, carry out mechanical stirring for 30 minutes, then feed compressed air and stir for 30 minutes, and continue to...

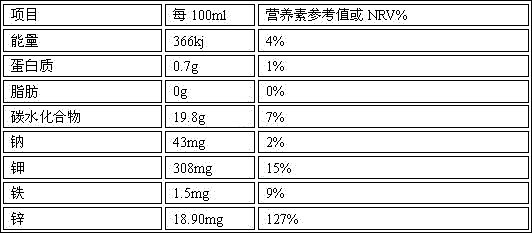

Embodiment 2

[0094] Take 4000kg of fresh red pears, sort them, remove the stalks, clean them, then crush them with a pulverizer, grind them with colloids, pump them into a closed 5m3 stainless steel fermentation tank, add 780Kg of brown sugar and 1kg of red pear enzyme strains, It is 18.4 degree [°Brix] to add 0.75kg red pear enzyme bacterial classification to detect that the sugar content of fermented liquid is 18.4 degrees. The first six days are the first stage of fermentation, that is, the vaporization stage. Mechanical stirring is performed for 30 minutes every day, and then the pressure is 8kg / cm 2 Stir with compressed air for 30 minutes (the air pressure is 8kg / cm 2 Before entering the fermentation tank, it has undergone purification treatment such as pickling, alkali washing and air filter, the same below) 810kg of organic brown sugar is continuously added. That is the saccharification stage. Every three days, carry out mechanical stirring for 30 minutes, then feed compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com