Anatase titanium dioxide nanomaterial with controllable and highly active crystal face exposed, its preparation method and application

An anatase-type titanium dioxide and nanomaterial technology, applied in the field of nanomaterials, can solve the problems of high recombination rate of photogenerated electron-hole pairs, cumbersome steps, easy agglomeration of titanium dioxide nanocrystals, etc., and achieve efficient visible light catalytic antibacterial performance, good The effect of the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing an anatase titanium dioxide nanomaterial exposing a controllable highly active crystal face, specifically comprising the following steps:

[0033] (1) Weigh water and ammonium fluoride at a molar ratio of 1 to 10:5 to prepare solution A;

[0034] (2) Add titanium tetrachloride solution in solution A, stir 0.5h with the speed of 800r / min, make solution B;

[0035] (3) Put the solution B into a polytetrafluoroethylene reactor, react in a drying oven at 170-210°C for 8-24 hours, and then cool to room temperature;

[0036] 4) Pour off the supernatant in the hydrothermal reaction kettle, and wash the solid-liquid mixture at the bottom in a 10000rpm centrifuge with water for three times;

[0037] 5) The precipitate obtained in step 4) is washed several times with absolute ethanol and deionized water successively;

[0038] 6) drying the washed precipitate obtained in step 5) at 60° C. for 6 hours to prepare anatase titanium dioxide nanomaterials with c...

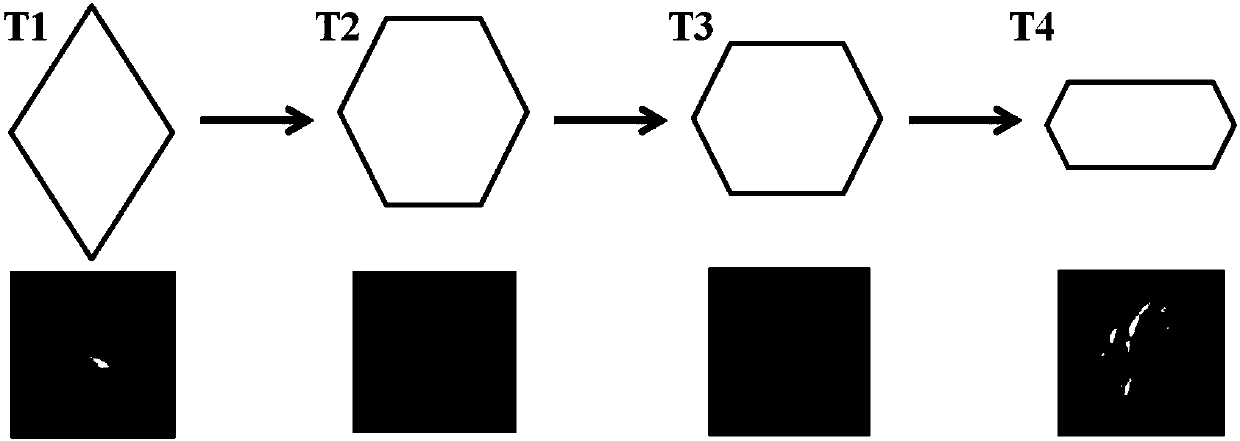

Embodiment 1

[0040] Weigh 1.7g of ammonium fluoride and dissolve it in 10mL of water. After stirring at a constant speed to dissolve, add 2mL of titanium tetrachloride, continue to stir at a speed of 800r / min for 30min, transfer to a polytetrafluoroethylene-lined autoclave, and react at 180°C for 12h. After cooling down to room temperature, put the reaction solution in a centrifuge at 10,000rpm, wash it with water for three times, then wash the obtained precipitate with absolute ethanol and deionized water for more than three times, and then dry it at 60°C for 6 hours to obtain the exposed The anatase titanium dioxide nanomaterial (marked as T1) with controlled high-activity crystal plane, the ratio of {001} crystal plane and {101} crystal plane of the material is 1%, and the size is 50-70nm.

Embodiment 2

[0042] Weigh 1.2g of ammonium fluoride and dissolve it in 10mL of water. After stirring at a constant speed to dissolve, add 2mL of titanium tetrachloride, continue to stir at a speed of 800r / min for 30min, transfer to a polytetrafluoroethylene-lined autoclave, and react at 210°C for 8h. After cooling down to room temperature, put the reaction solution in a centrifuge at 10,000rpm, wash it with water for three times, then wash the obtained precipitate with absolute ethanol and deionized water for more than three times, and then dry it at 60°C for 6 hours to obtain the exposed The anatase titanium dioxide nanomaterial (marked as T2) with controlled high-activity crystal plane, the proportion of {001} crystal plane and {101} crystal plane of the material is 10%, and the size is 50-70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com